Slag micro-powder dry mixed mortar

A technology of slag powder and dry-mixed mortar, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example one (inner wall plastering dry-mixed mortar):

[0034] formula:

[0035] Slag powder: 25Kg Fly ash: 7Kg

[0036] Machine-made sand: 68Kg (fineness less than 4mm) Compound activator: 0.4Kg

[0037] Hydroxypropyl methylcellulose: 0.015Kg Wood fiber: 0.4Kg

[0038] The composite activator is a mixture of sodium silicate and sodium thiosulfate with a weight ratio of 1:1.

[0039] Preparation:

[0040] After the various raw materials are accurately measured according to the above formula, the target product is obtained by mixing and forced mechanical stirring evenly.

Embodiment 2

[0041] Example two (external wall plastering dry-mixed mortar):

[0042] formula:

[0043] Slag powder: 25Kg Fly ash: 7Kg

[0044] Machine-made sand: 68Kg (fineness less than 4mm) Compound activator: 0.4Kg

[0045] Hydroxypropyl methylcellulose: 0.015Kg Wood fiber: 0.4Kg

[0047] The composite activator is a mixture of sodium silicate and sodium thiosulfate in a weight ratio of 1:1.

[0048] Preparation:

[0049] After the various raw materials are accurately measured according to the above formula, the target product is obtained by mixing and forced mechanical stirring evenly.

[0050] During the construction process, the water consumption is calculated according to the standard water consumption with a slurry diffusion diameter of 150±5 mm. Before construction, the wall surface should be fully moistened, and the materials should be fully mixed evenly to produce better strength.

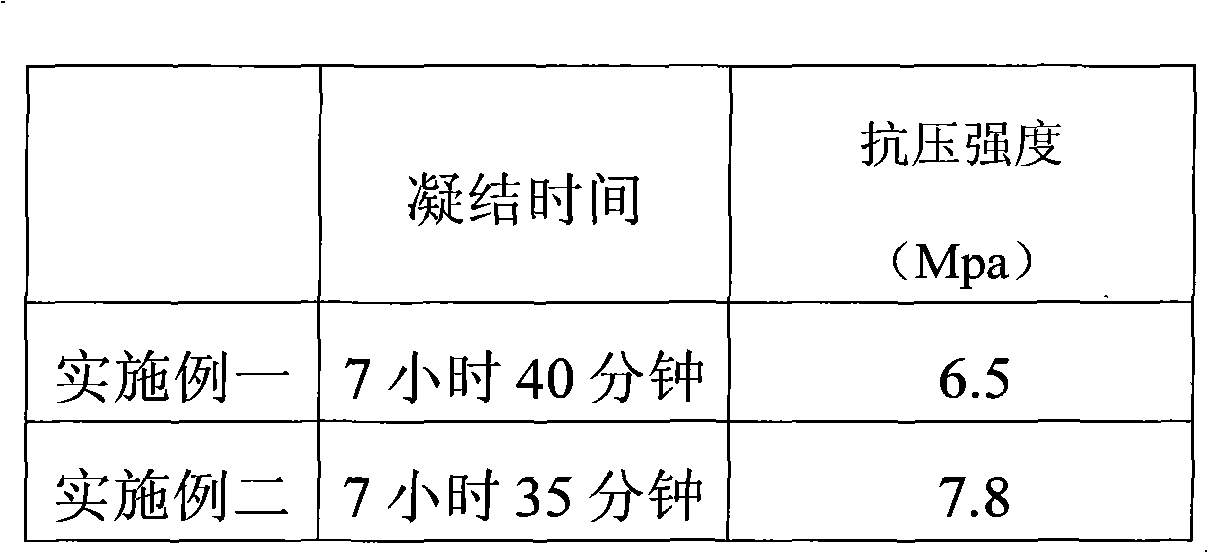

[0051] According to the standard method used in my country's construction indu...

Embodiment 3

[0053] Example three (inner wall plastering dry-mixed mortar):

[0054] formula:

[0055] Slag powder: 22Kg Fly ash: 9Kg

[0056] River sand: 73Kg (fineness less than 4mm) composite activator: 0.35Kg

[0057] Phosphated starch: 0.012Kg polyacrylonitrile fiber: 0.45Kg

[0058] The composite activator is a mixture of sodium silicate and calcium oxide with a weight ratio of 1:1.

[0059] Preparation:

[0060] After the various raw materials are accurately measured according to the above formula, the target product is obtained by mixing and forced mechanical stirring evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com