Preparation method of mixed polyether-polyester polyurethane/epoxy damping composite

A damping composite material, polyester polyurethane technology, applied in the direction of polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesive types, etc., can solve the incompatibility of polyester polyols, complicated synthesis process, reactive Harsh conditions and other problems, to achieve the effect of adjustable product performance, simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

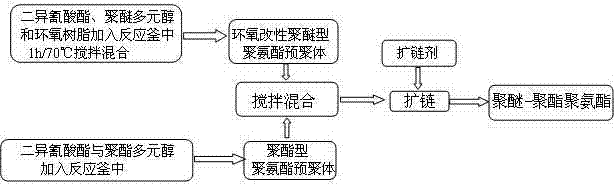

Method used

Image

Examples

preparation example Construction

[0035] ① Preparation of epoxy modified polyether prepolymer:

[0036] Add polyether polyol into the reaction kettle, heat at 100~110°C, and dehydrate under high vacuum for 1~2 hours; lower the temperature to below 40°C, blow dry nitrogen to release the vacuum; under the protection of nitrogen, stir and add diisocyanate ( Calculate the addition amount according to the preset NCO% content) into the prepolymer reactor, then add the dehydrated polyether polyol, heat it properly (due to the exothermic reaction), make the temperature rise to 80~100℃, and keep it warm for 1~3 hour, then add epoxy resin to react for 2 hours, and cool down to 40°C to obtain epoxy-modified polyether prepolymer.

[0037] ② Preparation of polyester prepolymer:

[0038]Add the polyester polyol into the dehydration kettle, heat at 100~140°C, and dehydrate under high vacuum for 1~2 hours; lower the temperature to below 40°C, pass through dry nitrogen to release the vacuum; under the protection of nitrogen, ...

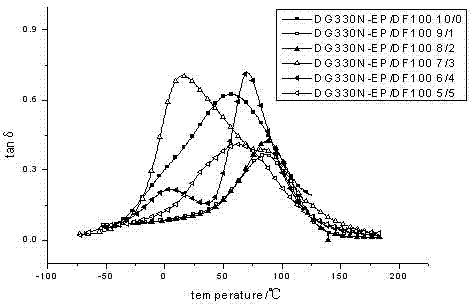

Embodiment 1

[0044] ① Add polyether polyol PPG (brand DG330N, hydroxyl value 32~36mgKOH / g) into the reaction kettle, heat at 100~110°C, dehydrate under high vacuum for 1~2 hours; lower the temperature below 40°C, and pass dry nitrogen Release the vacuum; under the protection of nitrogen, stir and continuously add TDI-80 diisocyanate (preset NCO% content is 4%) to the prepolymer reactor, then add dehydrated polyether polyol, heat (also exothermic reaction ), raise the temperature to 80~100°C, keep it warm for 1~3 hours, then add E-44 epoxy resin to react for 2 hours, and cool down to 40°C to obtain epoxy modified polyether prepolymer.

[0045] ② Add polyester polyol PET (brand DF100, hydroxyl value 100±5mgKOH / g) into the dehydration kettle, heat at 100~140°C, dehydrate under high vacuum for 1~2 hours; lower the temperature to below 40°C, and pass dry nitrogen into it Release the vacuum; under the protection of nitrogen, stir and continuously add MDI diisocyanate (preset NCO% content is 4%) ...

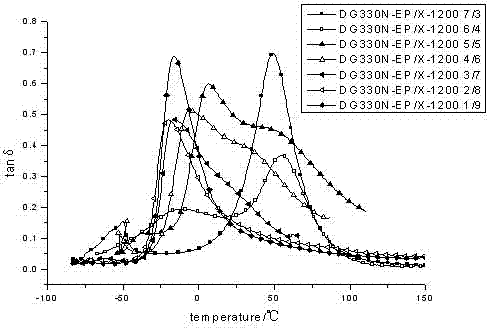

Embodiment 2

[0048] The polyester polyol PET among the embodiment 1 is changed into PEA (brand X-1200, hydroxyl value 73mgKOH / g) and MDI is changed into TDI, prepares TDI-PEA; DG330N polyether prepolymer, the mass ratio of epoxy modified polyether type / polyester type prepolymer is 10 / 0, 9 / 1, 8 / 2, 7 / 3, 6 / 4, 5 / 5, Measure the actual NCO% to be 4.1±0.2%; Stir and add the pre-melted chain extender MOCA, enter the mold for curing, preheat the mold at 90°C, and hot press; demould and post-vulcanize to obtain polyether (PPG)-polyester (PEA) polyurethane / epoxy damping material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com