Method for preparing novel polyether-polyester polyurethane material

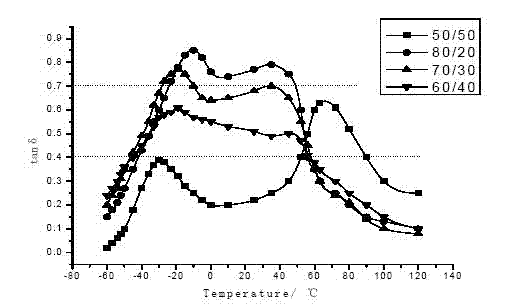

A technology of polyester polyurethane and polyether, which is applied in the field of polyurethane material preparation, can solve the problems of polyester polyol incompatibility, harsh reaction conditions, and high production cost, and achieve wide temperature range damping performance, low production cost, and high-quality products Performance adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

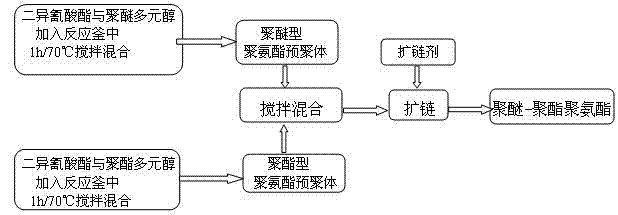

Method used

Image

Examples

Embodiment 1

[0037] ①Add polyether polyol DG330N (polyether polyol of glycerin, propylene oxide and ethylene oxide, hydroxyl value 32~36mgKOH / g) into the reaction kettle, heat at 100~110℃, and dehydrate under high vacuum for 1~2 hours ;Reduce the temperature below 40°C, blow dry nitrogen to release the vacuum; under the protection of nitrogen, add TDI-80 diisocyanate (preset NCO% content is 5%) into the prepolymer reactor continuously with stirring, and then add The dehydrated polyether polyol is properly heated (due to the exothermic reaction) to raise the temperature to 80-100°C, keep it warm for 1-3 hours, and then cool down to 40°C to obtain TDI-DG330N polyether prepolymer.

[0038]② Add polyester polyol PL1201 (phthalic anhydride polyester polyol, hydroxyl value 120±5mgKOH / g) into the dehydration kettle, heat at 100~140°C, dehydrate under high vacuum for 1~2 hours; lower the temperature to below 40°C, pass Introduce dry nitrogen to release the vacuum; under the protection of nitrogen,...

Embodiment 2

[0043] ①Use polyether polyol (PTMG2000, hydroxyl value 53~59mgKOH / g), preset NCO% content as 6%, and prepare TDI-PTMG2000 polyether prepolymer.

[0044] ② Use polyester polyol (PEA2000, hydroxyl value 55-62mgKOH / g) with a preset NCO% content of 6% to prepare MDI-PEA2000 polyester prepolymer.

[0045] ③ Mix TDI-PTMG2000 polyether prepolymer and TDI-PEA2000 polyester prepolymer in a ratio of 1:1, and measure the actual NCO% content to be 6.1±0.2; stir and add pre-melted chain extender MOCA to obtain a casting Type polyether-polyester polyurethane elastomer material.

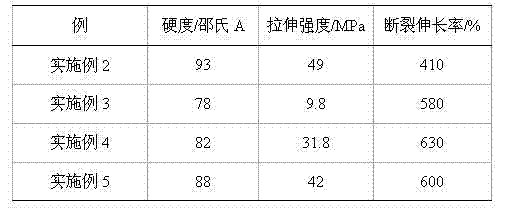

[0046] The physical and mechanical properties of polyether-polyester polyurethane are shown in Table 2.

Embodiment 3

[0048] ①Use polyether polyol (PPG1000, hydroxyl value 53~59mgKOH / g), preset NCO% content as 5.5%, and prepare HDI-PPG2000 polyether prepolymer.

[0049] ② Use polyester polyol (PBA2000, hydroxyl value 55.6mgKOH / g) with a preset NCO% content of 5.5% to prepare HDI-PBA2000 polyester prepolymer.

[0050] ③ Mix HDI-PPG2000 polyether prepolymer and HDI-PBA2000 polyester prepolymer in a ratio of 1:1, and add chain extender propylene glycol PDO according to NCO:OH = 1.05:1 to prepare castable polyether- Polyester polyurethane elastomer material.

[0051] The physical and mechanical properties of polyether-polyester polyurethane are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com