Method for producing lutein from microalgae

A technology of lutein and microalgae, applied in the direction of fermentation, can solve the problems of restricting the industrialization process of lutein, high cost of large-scale cultivation of microalgae, low lutein content and lutein yield, etc. The effect of high quality, rapid accumulation and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Add the following heterotrophic medium and water to 2.8L in a 5L bioreactor, then steam sterilize it, then insert Chlorella pyrenoidosa when the temperature drops to 30°C, and start heterotrophic culture.

[0076] Heterotrophic culture conditions: the temperature is 30±1°C, the air flow rate is 1vvm, the pH is less than 8.0, and the dissolved oxygen is controlled above 15%.

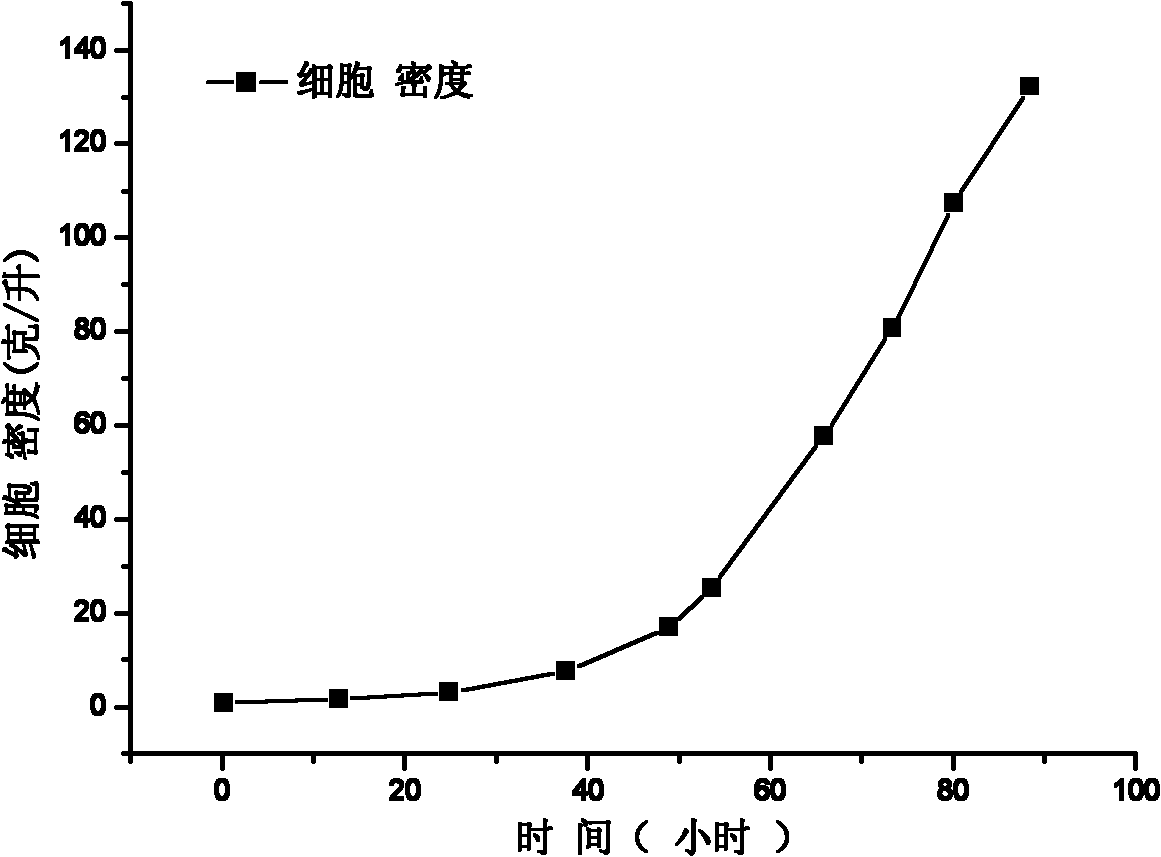

[0077] Feed was fed for the first time 53.9 hours after inoculation, and then fed every 5 to 8 hours for a total of 4 times, until the dry weight of cells reached 132.2g / L at 88.40 hours (see figure 1 ), at this time the heterotrophic culture was completed and transferred to light-induced culture.

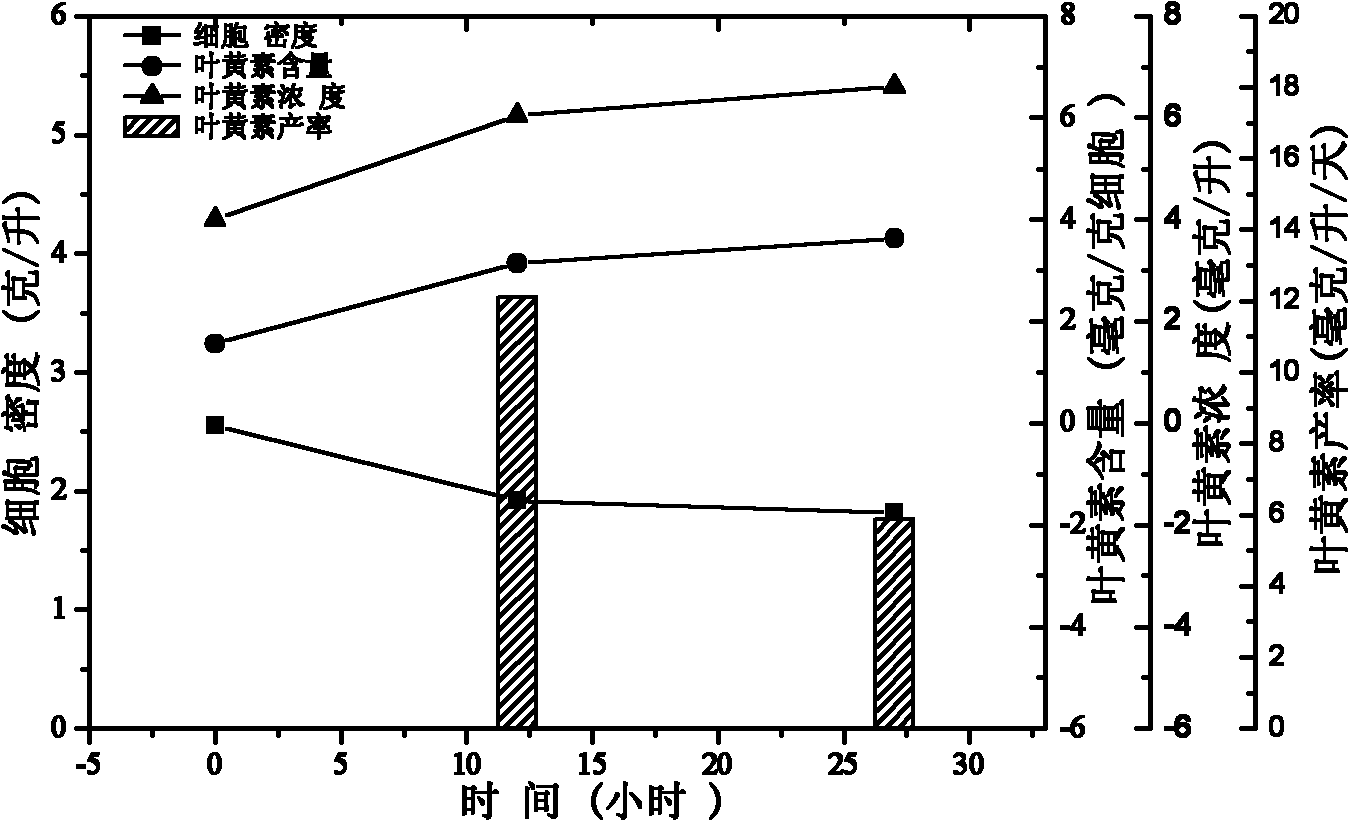

[0078] Dilute the high-density algae liquid after the heterotrophic culture to 2.55g / L, add the following light-induced medium, and transfer it to a 3L flat-plate photobioreactor for light-induced culture. Light-induced culture conditions: the temperature is maintained at 28-33°C, the air flow rate is ...

Embodiment 2

[0090] Add the following heterotrophic medium and tap water to a 50L bioreactor to 25L, then sterilize at 121°C for 20min, then insert Chlorella pyrenoidosa according to 10% of the working volume when the temperature drops to about 30°C, and start heterotrophic Raise and cultivate.

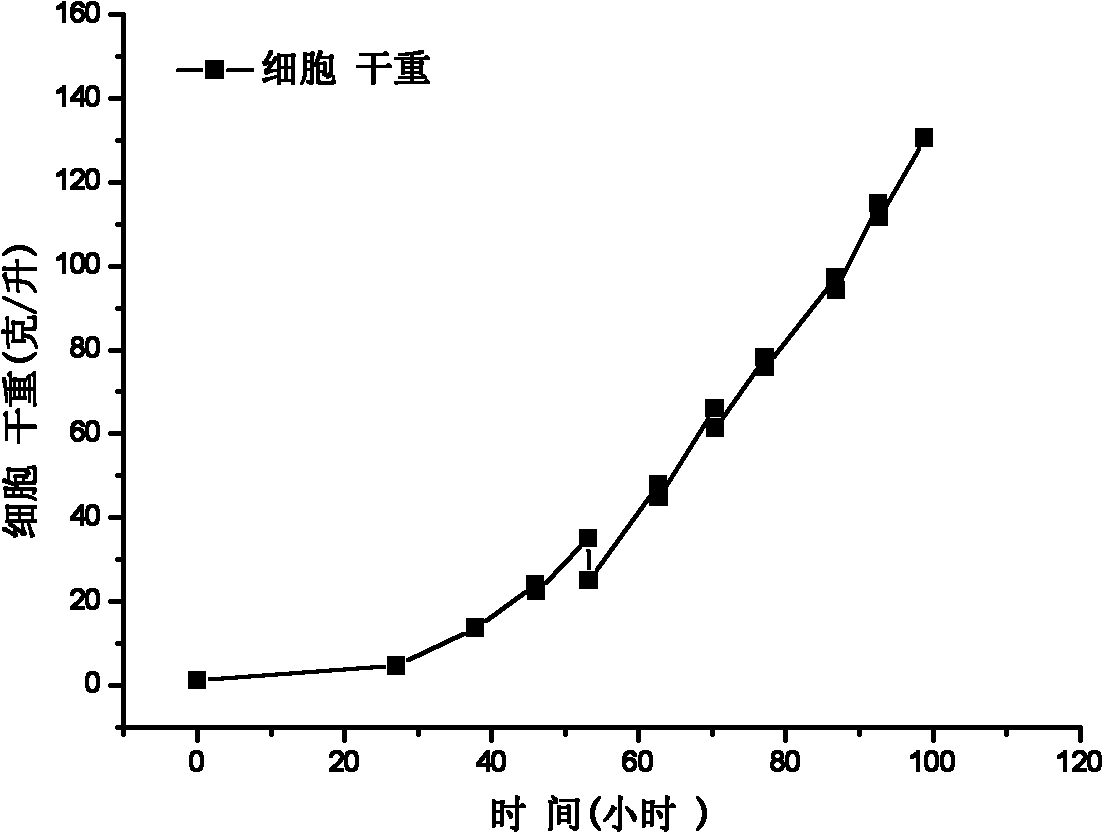

[0091] Heterotrophic culture conditions: the temperature is 30°C, the air flow rate is 1vvm, the pH is 6.0-8.0, and the dissolved oxygen is controlled above 15%. During the cultivation process, when the glucose was consumed, the carbon source was supplemented, and when the urea was consumed, the nitrogen source was supplemented. After adding carbon source 6 times, the algae cell density reached 130.5g / L at 98.89h after adding nitrogen source 3 times (see image 3 ).

[0092] Dilute the high-density algae after heterotrophic culture to 2.01g / L, add light-induced medium, and transfer to a 10L cylindrical photobioreactor for light-induced induction.

[0093] Light-induced culture conditions: natur...

Embodiment 3

[0095] Add the following heterotrophic medium and tap water to a 50L bioreactor to 25L, then sterilize at 121°C for 20 minutes, then insert Chlorella vulgaris into 13% of the working volume when the temperature drops to about 30°C, and start heterotrophy to cultivate.

[0096] Heterotrophic culture conditions: temperature is 30°C, air flow is 1vvm, pH is less than 9.0. During the cultivation process, when the carbon source was exhausted, glucose was supplemented, and when the nitrogen source was exhausted, potassium nitrate was supplemented. By adding carbon source and nitrogen source 5 times, the algae cell density reached 54.5g / L at 58.20h (see Figure 5 ).

[0097] Dilute the heterotrophically cultured high-density algae to about 3.2g / L, add light-induced medium, and transfer to a 30L flat-plate photobioreactor for light-induced culture outdoors. Light-induced culture conditions: natural temperature, natural light, and air flow of 1.0vvm. After 28 hours of light inducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com