Method for preparing copper tin sulfur film with preferred orientation

A preferred orientation, copper-tin-sulfur technology, applied in the field of preparation of copper-tin-sulfur thin films, can solve the problems of complex process routes and high preparation costs, and achieve the effect of low equipment requirements, low production costs, and large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

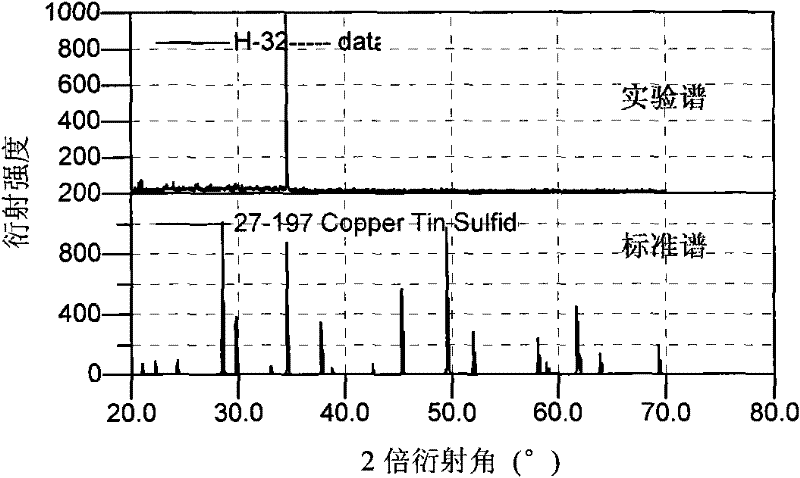

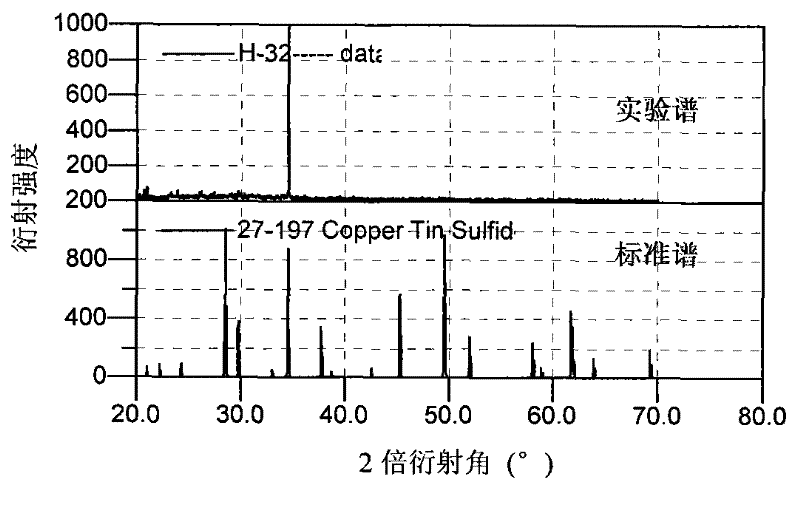

Image

Examples

Embodiment 1

[0025] a. Cleaning of the glass substrate: The glass substrate (size 2mm×2mm) was cleaned as described above.

[0026] b. Add 1.0 part of CuCl 2 2H 2 O, 1.327 parts of SnCl 2 2H 2 O and 1.791 CH 4 N 2 Put S into a glass bottle, add 39.789 parts of deionized water and 26.526 parts of ammonia water, and use ultrasonic vibration for more than 30 minutes to mix the substances in the solution evenly.

[0027] c. Drop the above solution onto the glass substrate placed on the homogenizer, and then start the homogenizer. The homogenizer rotates at 200 rpm for 5 seconds and at 3000 rpm for 15 seconds, so that the dripped solution is coated After uniformity, the substrate was dried at 100°C, and then the above-mentioned solution was dripped and spin-coated again, and then dried again. This was repeated 10 times, and a precursor thin film sample with a certain thickness was obtained on the glass substrate.

[0028] d. Put the precursor thin film sample obtained by the above process...

Embodiment 2

[0031] a. Cleaning of the glass substrate: The glass substrate (size 2mm×2mm) was cleaned as described above.

[0032] b. Add 1.0 part of CuCl 2 2H 2 O, 1.327 parts of SnCl 2 2H 2 O and 1.791 CH 4 N 2 Put S into 39.789 parts of ethylene glycol and mix evenly, add hydrochloric acid until the pH is 2.5, and use ultrasonic vibration for more than 30 minutes to make the substances in the solution evenly mixed.

[0033] c. Drop the above solution onto the glass substrate placed on the homogenizer, and then start the homogenizer. The homogenizer rotates at 200 rpm for 5 seconds and at 3000 rpm for 15 seconds, so that the dripped solution is coated After uniformity, the substrate was dried at 100°C, and then the above-mentioned solution was dripped and spin-coated again, and then dried again. This was repeated 10 times, and a precursor thin film sample with a certain thickness was obtained on the glass substrate.

[0034] d. Put the precursor thin film sample obtained by the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com