Pipe joint with functions of electricity defending wall

A pipe joint and anti-electric wall technology, which is applied in the field of pipe joints, can solve the problems that the two ends of the insulating water pipe are not directly connected together, cannot guarantee user safety, increase production costs, etc., and achieve simple structure, small size, and easy processing. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

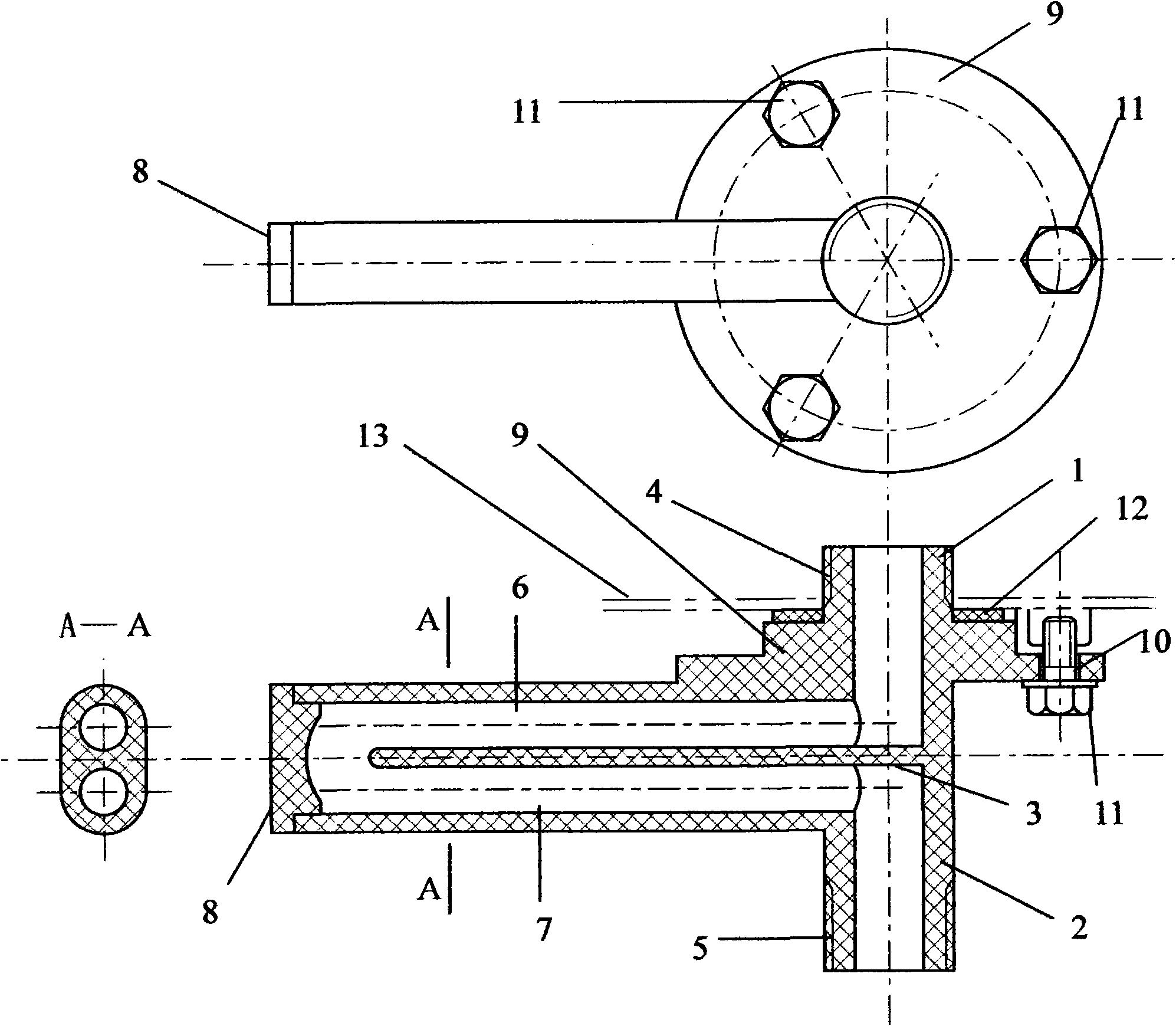

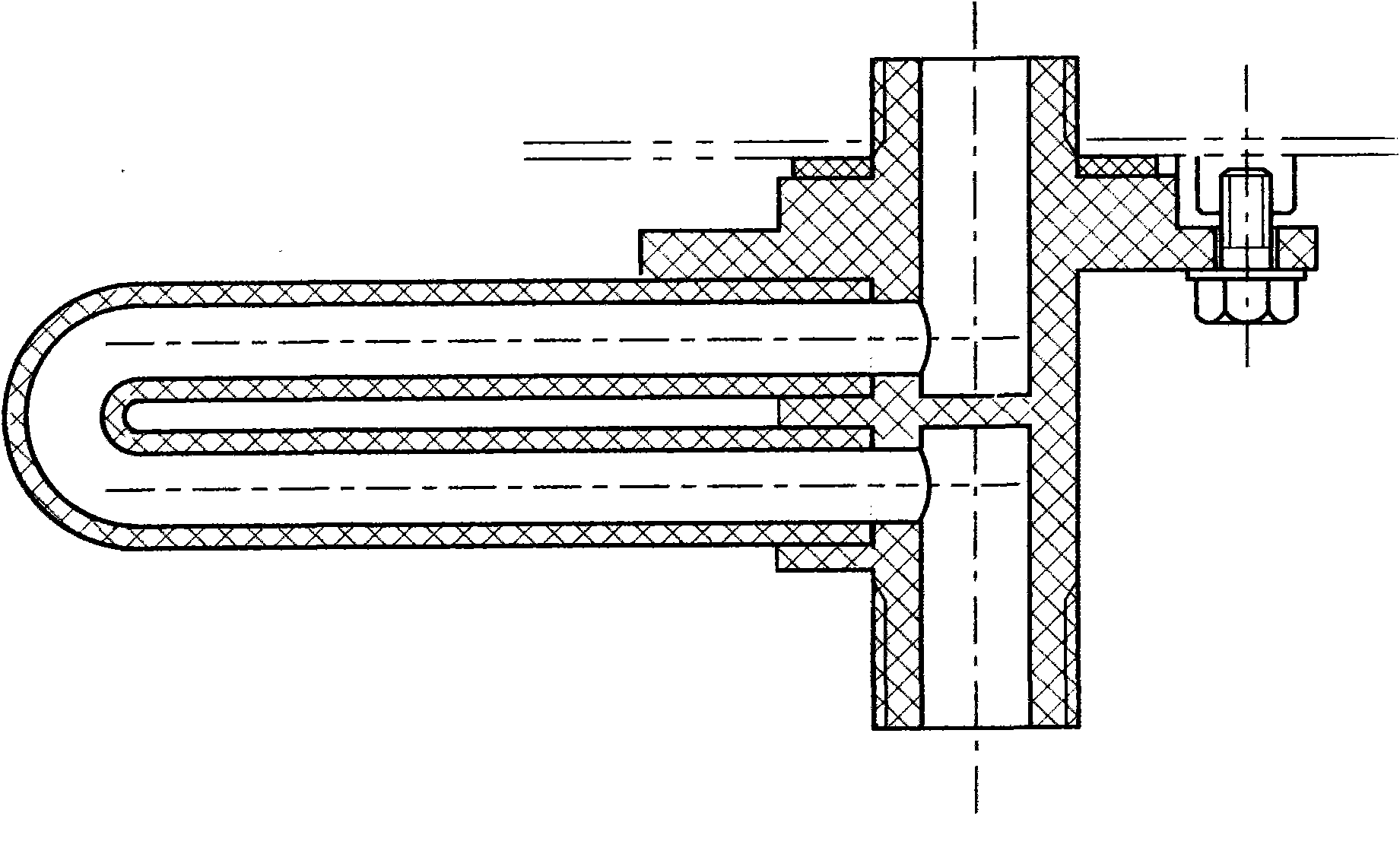

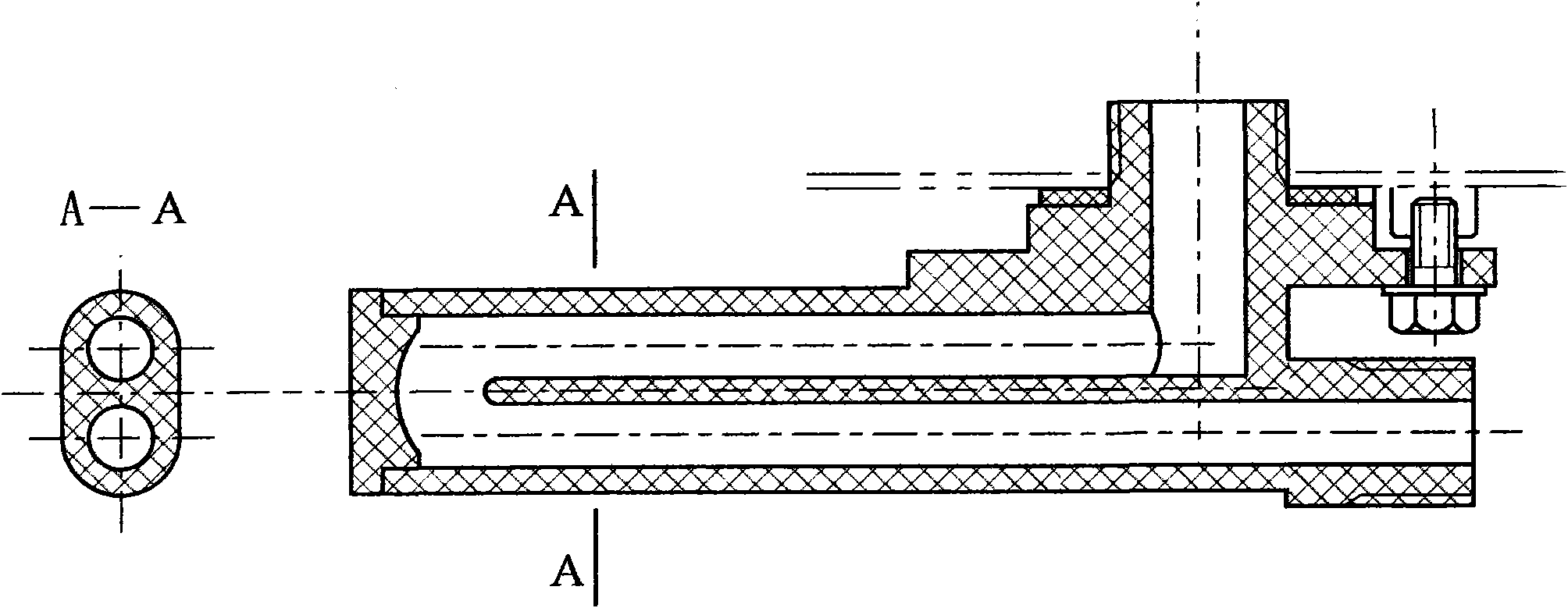

[0040] as attached figure 1 to attach Figure 9 As shown, the pipe joint with the function of the electric wall of the present invention, all its parts (except the bolt, which is made of metal material, which is an accessory of the pipe joint with the function of the electric wall) are all made of high insulation, high temperature resistance, water resistance It is made of decomposed and pressure-resistant plastic material.

[0041] as attached figure 1 As shown, the interface 1 and the interface 2 are directly connected, and the two are separated by a partition 3; the central axis of the interface 1 and the interface 2 is the same axis; there is a thread 4 on the interface 1, and a thread 5 on the interface 2; the U-shaped pipe is composed of The straight pipe 6, the straight pipe 7 and the bottom 8 are composed, and the inner cavity of the three is connected to form a U-shaped pipe; the interface 1 is connected to the straight pipe 6 and the inner cavity is connected, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com