Energy-saving and environment-friendly high-voltage closed bus

A closed busbar, energy-saving and environmentally friendly technology, applied in the field of high-voltage closed busbars, can solve the problems of equipment insulation and power grid safety operation threats, insulation and power grid safety operation threats, system capacitive current increase, etc., to reduce the skin effect, Avoid the generation of harmful overvoltage and reduce the effect of distributed capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

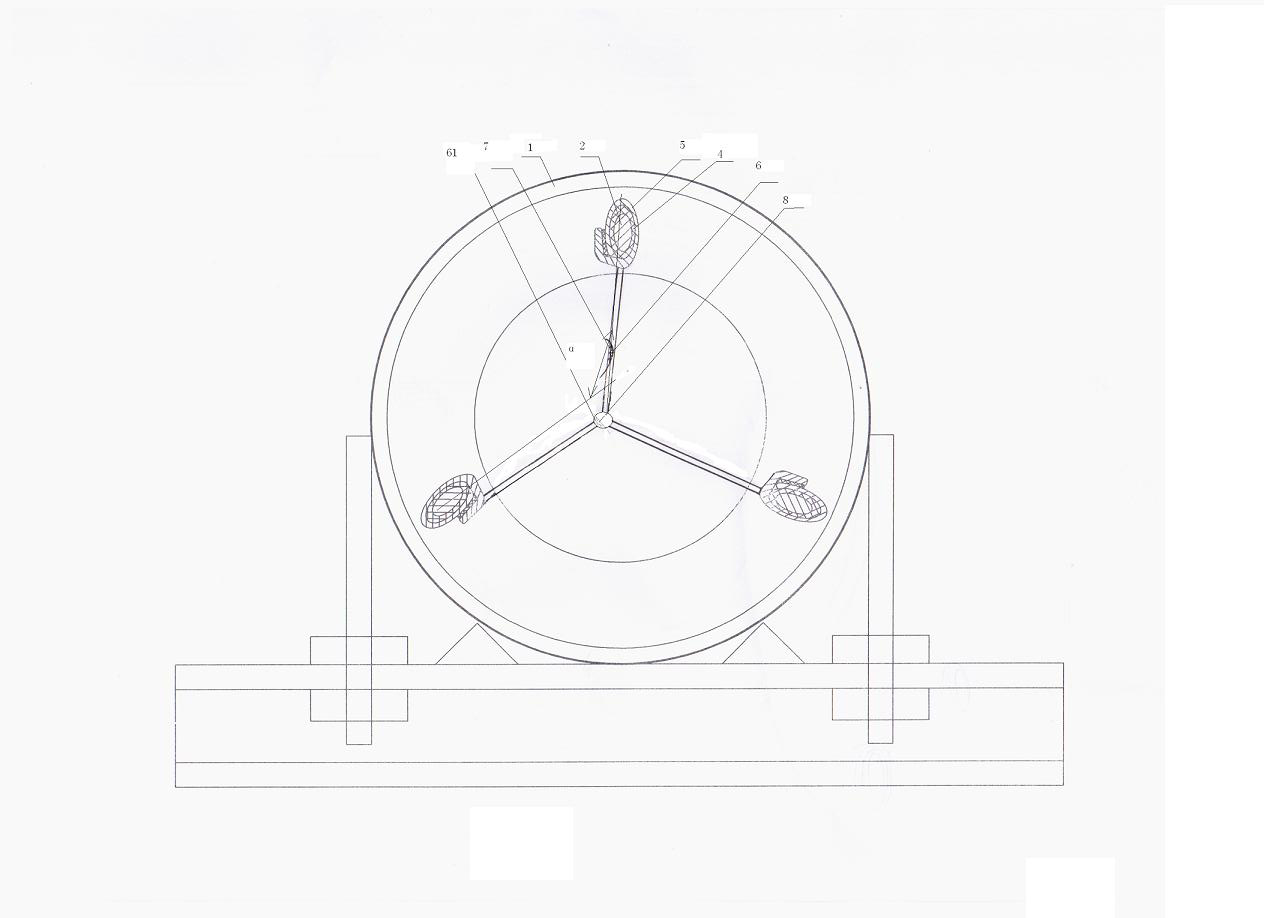

[0012] The invention relates to a segmented energy-saving high-voltage closed busbar with a special structure, which includes a casing 1 and three busbars 2, and the three busbars 2 are uniformly distributed in the closed casing 1, and the casing 1 can be processed by composite resin. It can also be made of aluminum alloy material. In order to further improve the safety of the busbar, it is preferable that the outer shell 1 is made of aluminum alloy material. The shape of the outer shell 1 is not limited, and it can be square or circular. Discharge at the tip to ensure the safety of the busbar. It is preferable to design the cross-section of the busbar 2 as a flat oval. The material of each busbar 2 is copper, and the outer circumference of the busbar 2 is respectively covered with an insulating jacket 4. XLPE cross-linked polyethylene with extremely small dielectric loss is processed. XLPE is the abbreviation of the English name of cross-linked polyethylene. Polyethylene is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com