P-type super-junction transverse double-diffusion metal oxide semiconductor tube

An oxide semiconductor, lateral double diffusion technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as depletion of P-type pillars and failure to fully deplete breakdown voltage at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

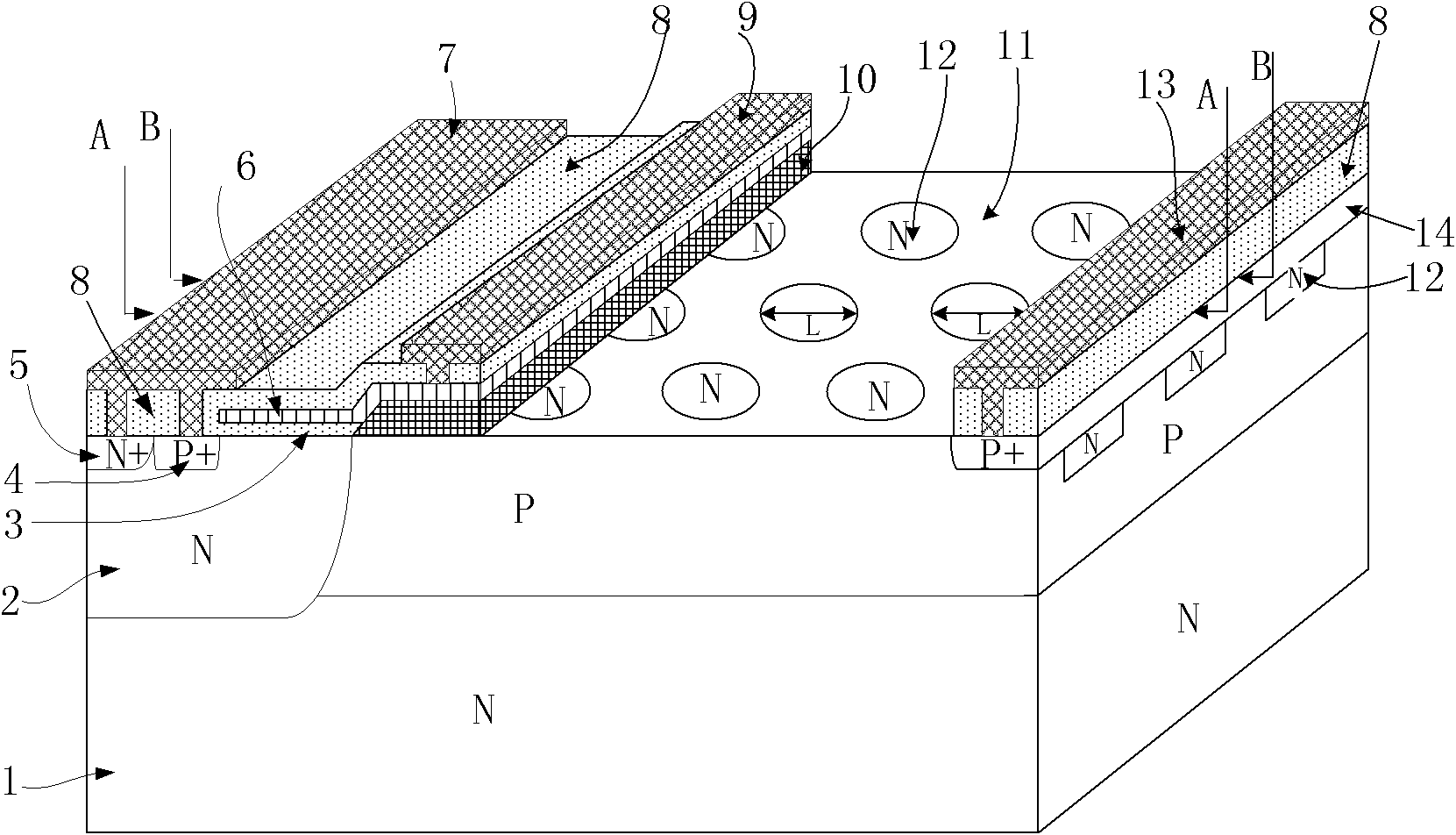

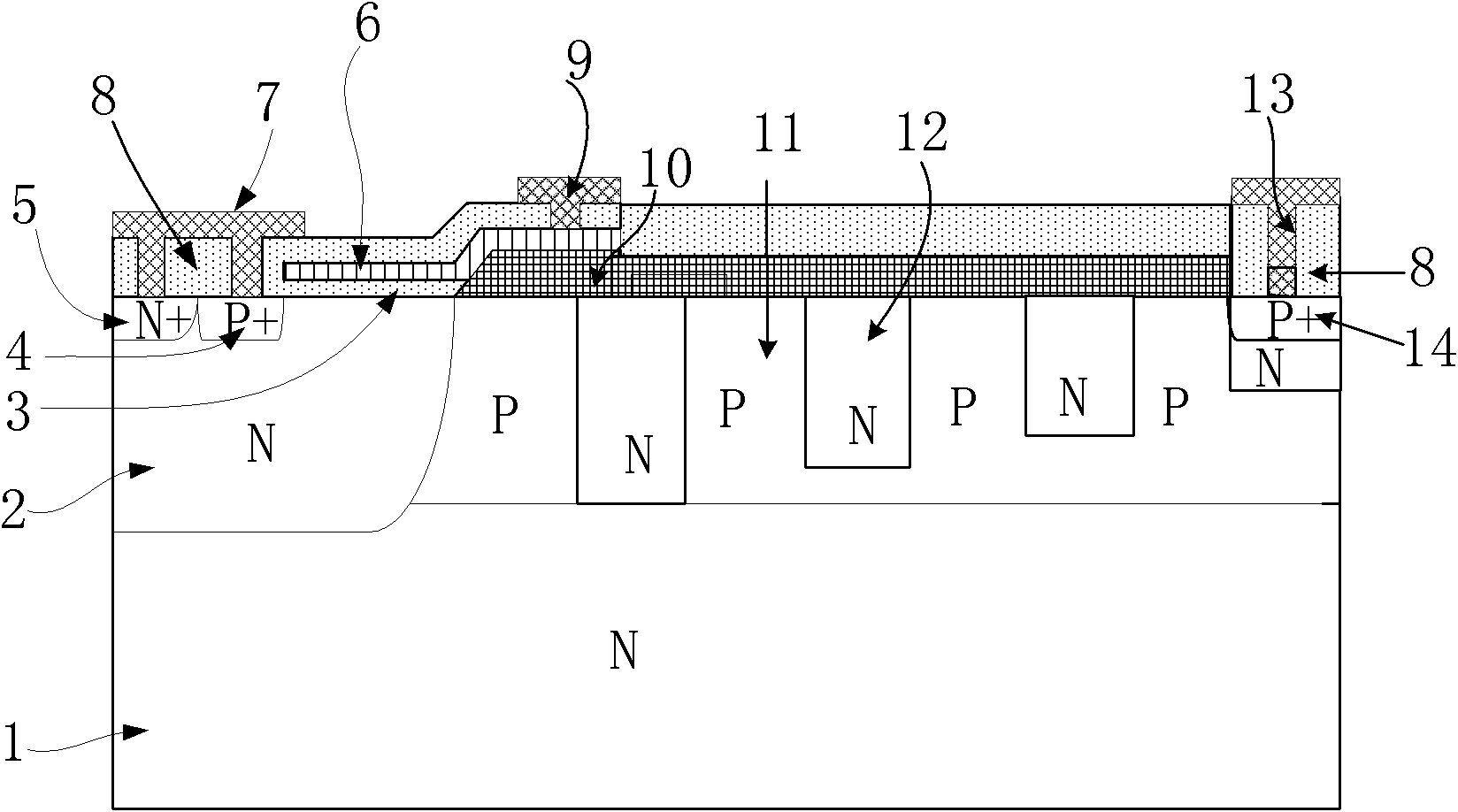

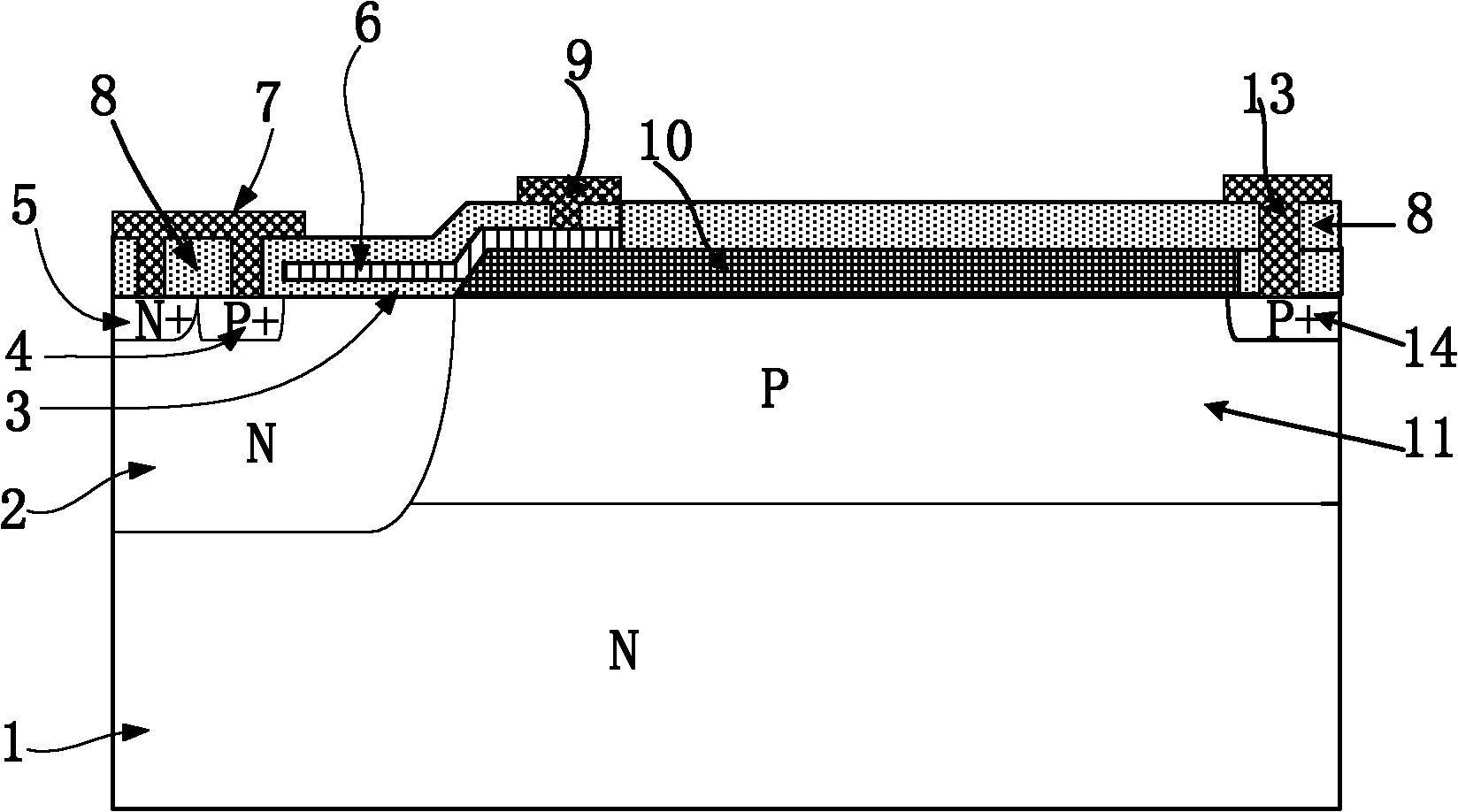

[0017] refer to figure 1 , a P-type superjunction lateral double-diffused metal oxide semiconductor transistor, comprising: an N-type substrate 1, a superjunction structure and an N-type body region 2 are arranged on the N-type substrate 1, and the superjunction structure is composed of a P-type epitaxial layer 11 and an N-type semiconductor region 12 embedded in the P-type epitaxial layer 11. A P-type source region 4, an N-type body contact region 5 and a gate oxide layer 3 are arranged above the N-type body region 2. In the super junction structure A P-type drain region 14 is arranged above the super junction structure, and a first-type field oxide layer 10 is arranged on the area outside the P-type drain region 14, and a polysilicon gate 6 and a polysilicon gate are arranged above the gate oxide layer 3. 6 extends from above the gate oxide layer 3 to above the first type field oxide layer 10, above the P type source region 4, the N type body contact region 5, the P type dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com