Method of manufacturing solid solution peforator patches and uses thereof

一种可溶性、微型针的技术,应用在制造和生产固体溶液穿孔器,贴剂注入/插入领域,能够解决浇注方法不适用大规模生产、微型针阵列很贵、复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

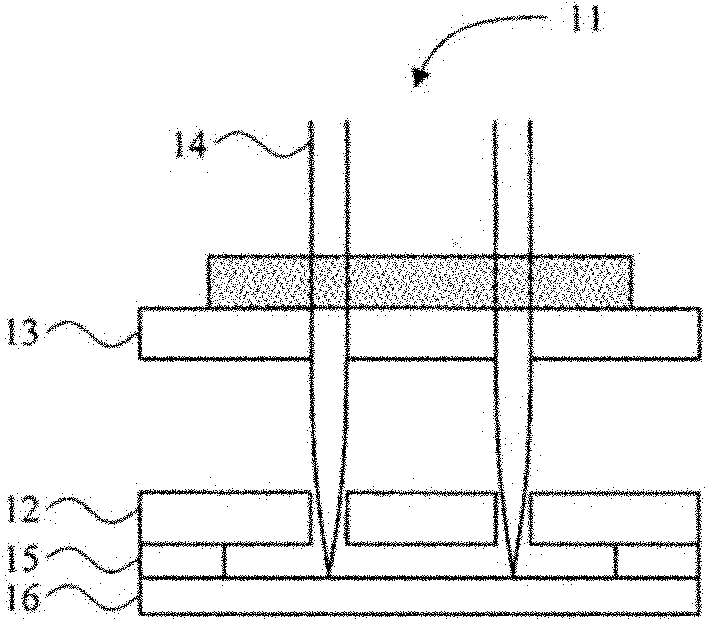

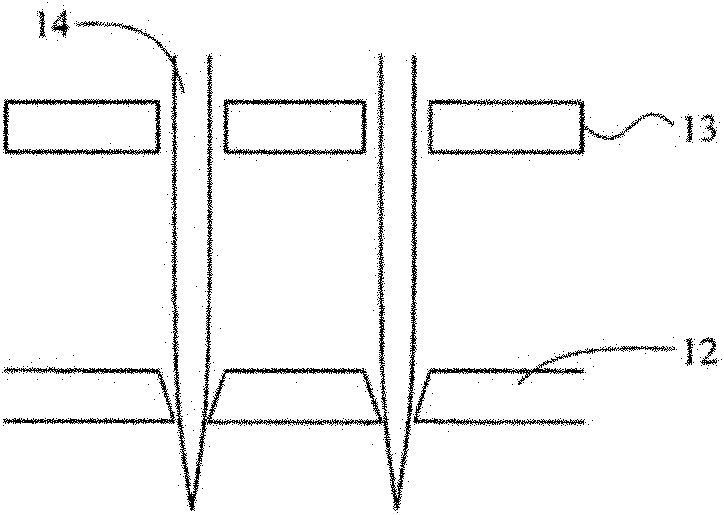

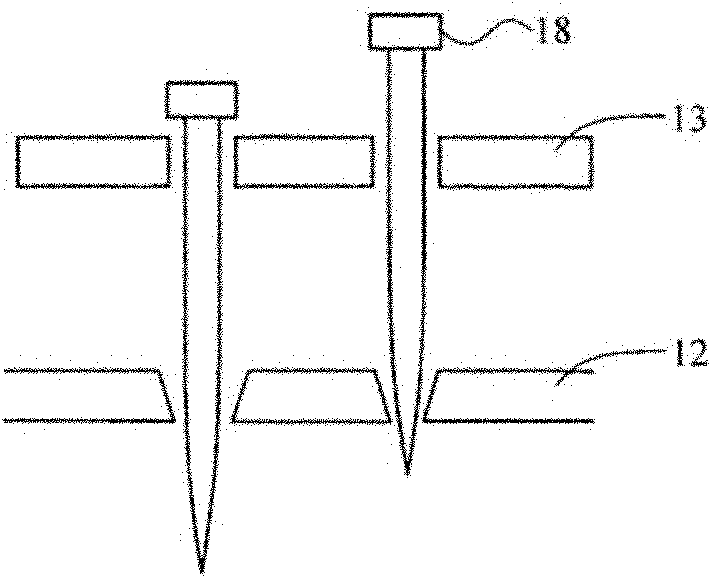

[0089] Example 1: Fabrication of positive master and SSP from silicon mold

[0090] Figure 1D Shown in is the hole 114 made in the glass by chemically etching a through hole in the photoresist film formed by photolithography, and the acupuncture needle alignment and passage hole 114. The tip of the needle passing through the hole is described. Pour PDMS over this side and let it cure overnight. 8% sodium methylcellulose hydrogel was poured on the silicon mold, and then centrifuged at 3000 rpm for 5 minutes. After centrifugation, the hydrogel was dried for one day and peeled from the mold. Figure 5 is an image of dissolvable microneedles made from cellulose. Figure 1F Additional micro-molds fabricated using CNC contouring grinder technology are described in .

example 2

[0091] Example 2: Compression break force and dissolution time of different components

[0092] Compression testing was performed with a dynamometer (NexyGen DF series), measuring the conical compressive force exerted by the microneedle upon snapping off. Test samples were prepared using different carbohydrate derivatives and sodium carboxymethylcellulose (SCMC). Mix 8% SCMC with deionized water. The time for complete dissolution of SCMC in 10 ml of deionized water at 300 rpm was measured. The results were weight normalized since the carbohydrate derivatives were added to fixed 8% SCMC hydrogels. The results are shown in Table 1.

[0093] Table 1

[0094]

[0095]

example 3

[0096] Example 3: Mechanical properties of different lactose components

[0097] Compression and dissolution tests were performed on different lactose components. When lactose was added, the tested granules dissolved faster and the compressive force increased. See Table 2.

[0098] Table 2

[0099]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com