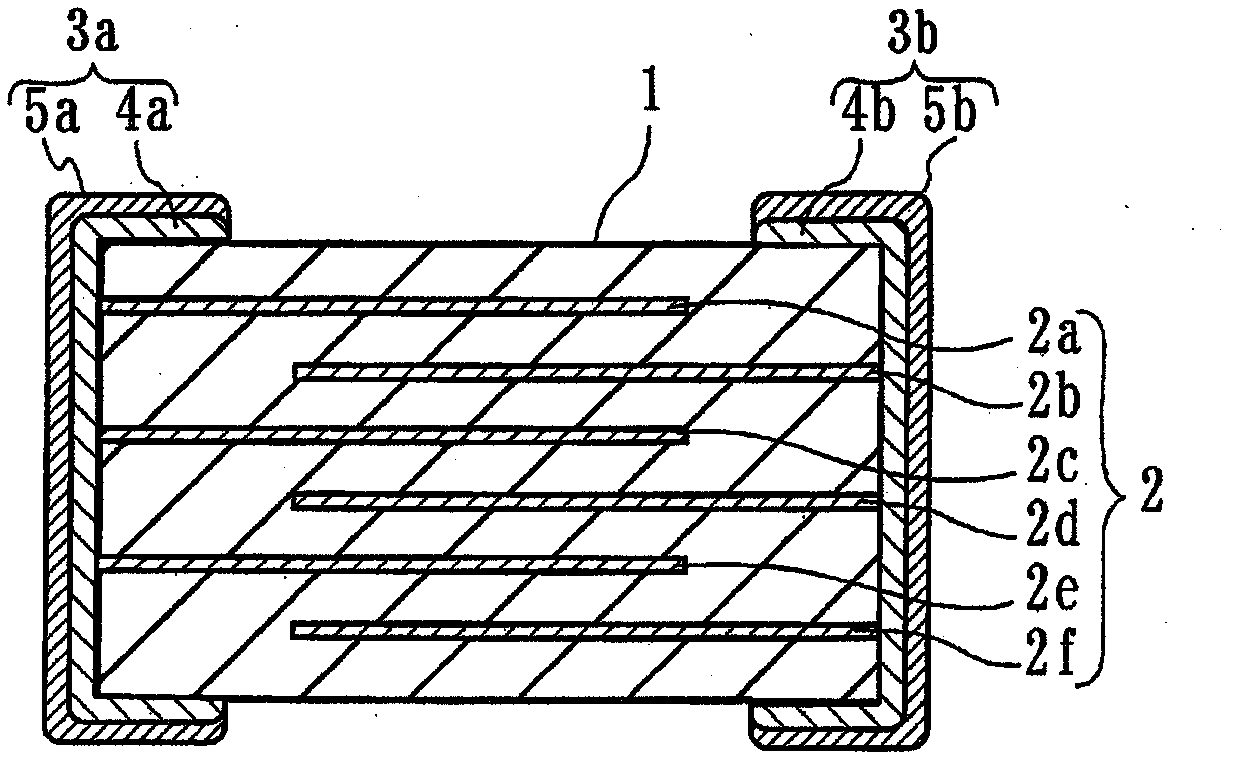

Multilayer electronic component

A kind of electronic parts, laminated technology, applied in the direction of fixed capacitance parts, electrical components, laminated capacitors, etc., can solve the problem of poor moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

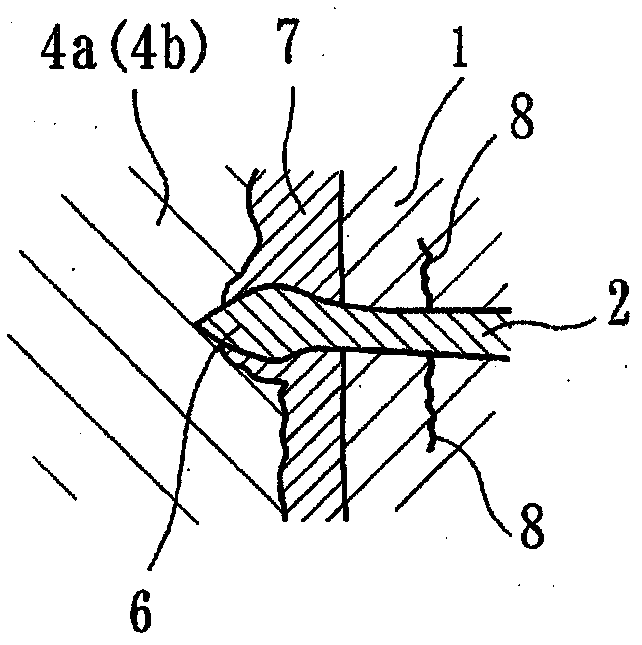

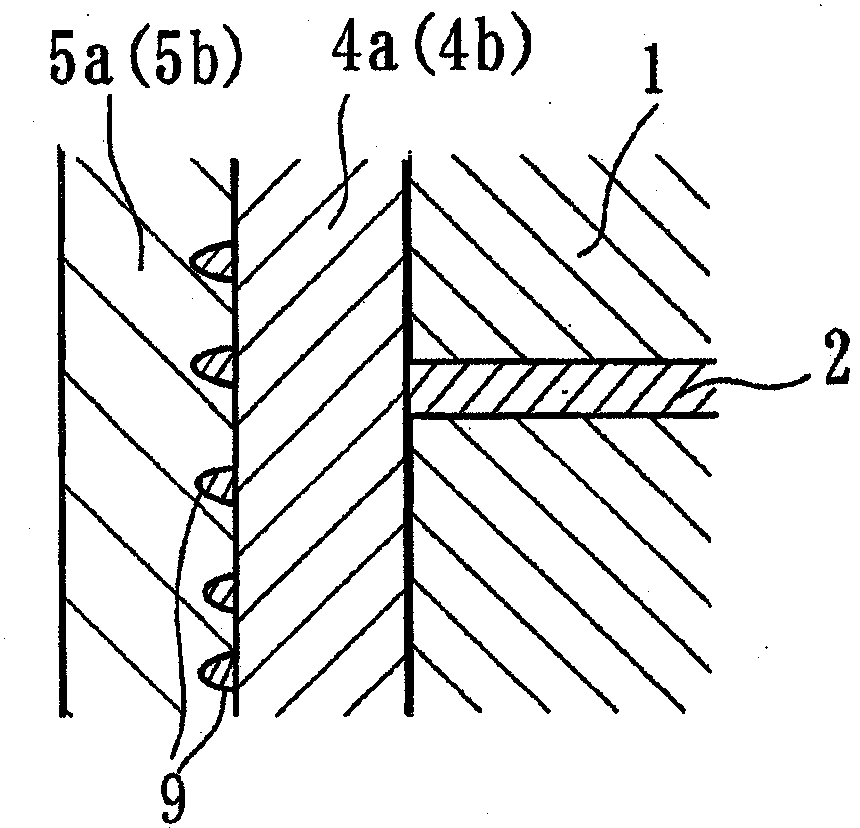

[0049] Next, examples of the present invention will be described in detail.

[0050] 〔Production of ceramic sintered body〕

[0051] First, as a ceramic base, weigh a specified amount of BaCO 3 and TiO 2 Next, these weighed objects were put into a ball mill together with PSZ (partially stabilized zirconia) balls and pure water, wet mixed and pulverized sufficiently, and dried to obtain a mixed powder.

[0052] Next, the mixed powder was calcined in the atmosphere at a temperature of 950°C for 2 hours, and then dry pulverized to produce BaTiO 3 Ceramic raw material powder as the main component.

[0053] Next, using ethanol as a solvent, a polyvinyl butyral-based binder was added, and the ceramic raw material powder was mixed and pulverized to obtain a ceramic slurry. Then, the above-mentioned ceramic slurry was molded using a doctor blade method to obtain a ceramic green sheet.

[0054] Next, a conductive paste for internal electrodes containing Ni as a main component was s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com