Method for detoxifying de-oiled jatropha curcas kernels

A technology of leprosy and tree species, applied in food science, animal feed, food preparation, etc., can solve the problems of no high-performance liquid chromatography, long extraction cycle, heavy workload, etc., achieve significant detoxification effect and shorten the extraction cycle , The effect of reducing the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

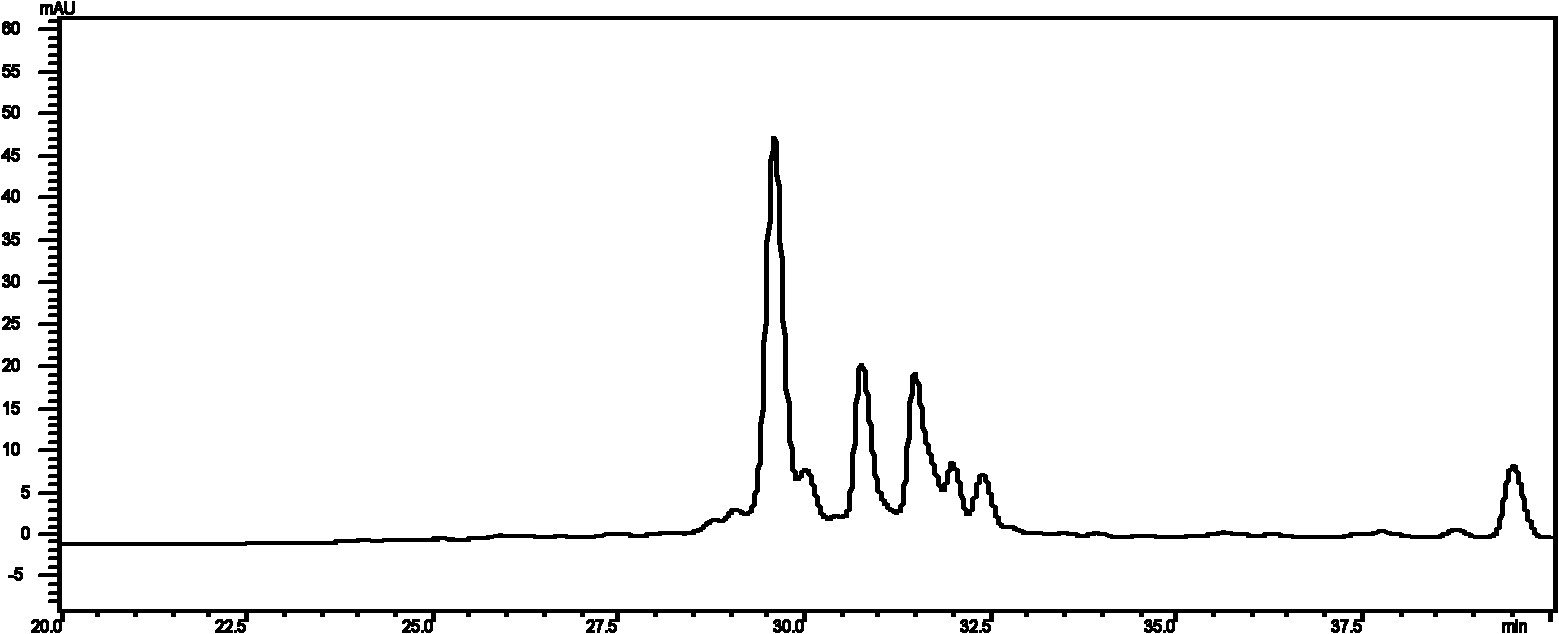

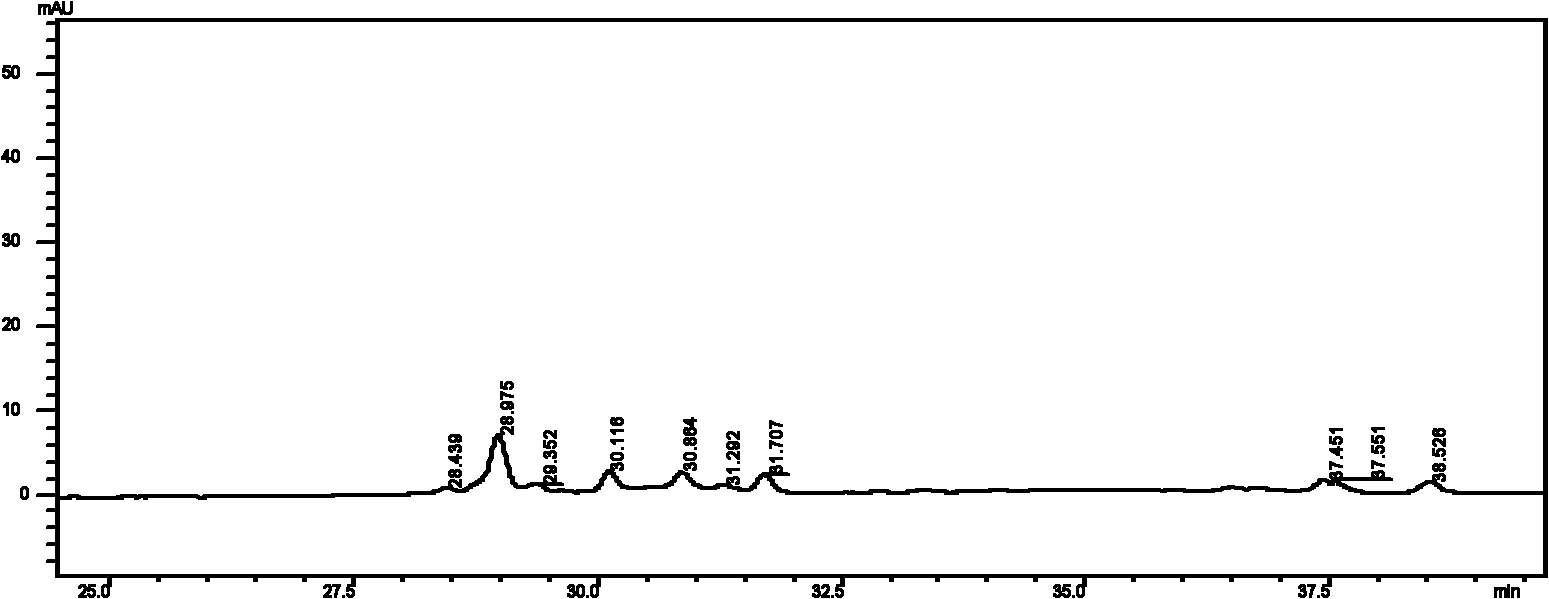

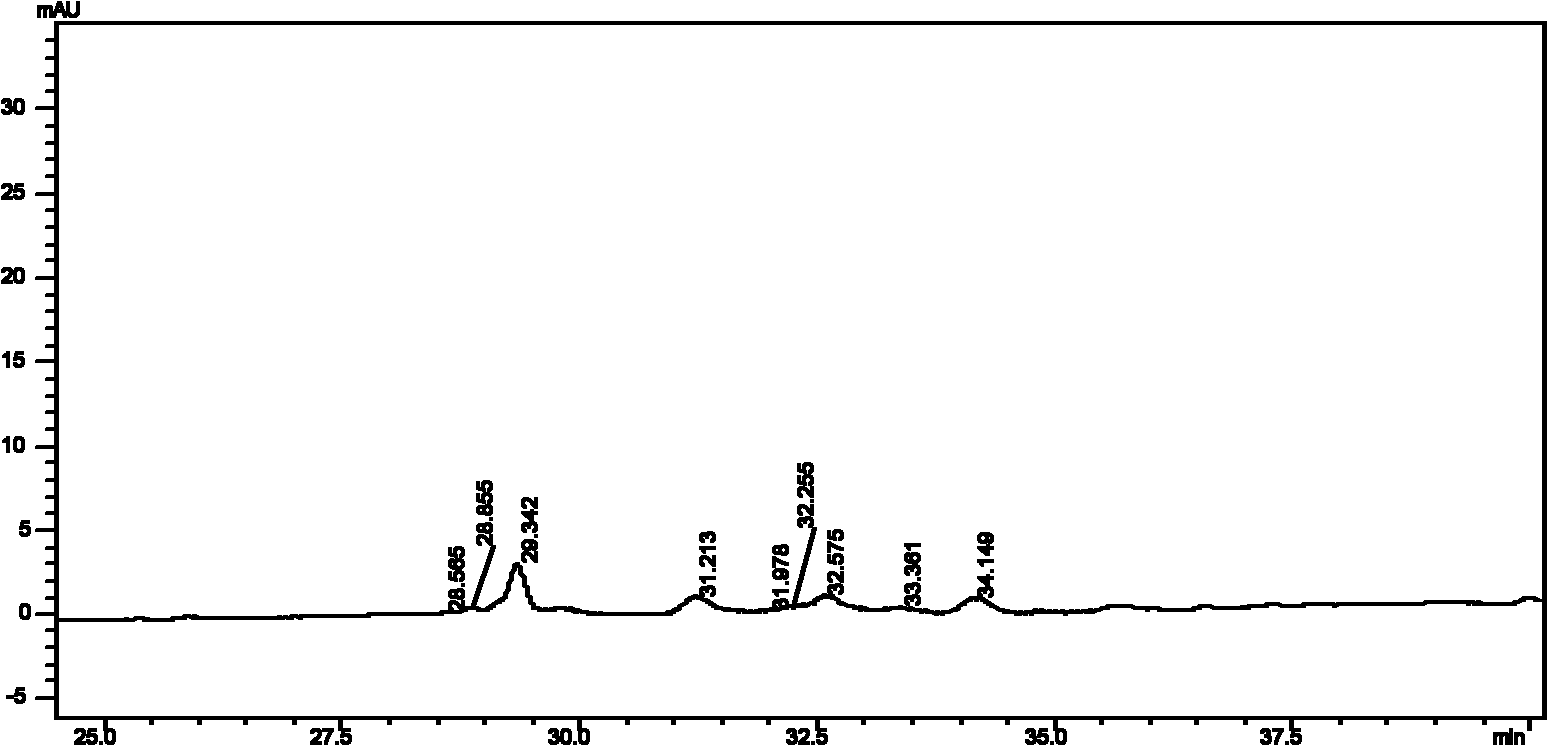

Image

Examples

Embodiment 1

[0031] Take Jatropha curcas seed kernels after cold pressing and deoiling and crush 100 g of granules with a 40-mesh sieve, then dry-steam them at a temperature of 115° C. and a pressure of 0.07 MPa for 20 minutes; 500ml of 95% industrial ethanol, and ultrasonically oscillate at a power of 150W for 28 minutes, repeat the operation once, filter and separate the oily meal and ethanol phase, let the ethanol in the oily meal dry naturally, and then the feed vegetable protein can be obtained.

Embodiment 2

[0033] Take Jatropha curcas seed kernels after cold pressing and deoiling and pulverize 100g of particles through a 40-mesh sieve, then dry-steam them at a temperature of 118°C and a pressure of 0.05MPa for 25min; 500ml of industrial ethanol, and ultrasonically oscillate at a power of 150W for 25 minutes, repeat the operation twice, filter and separate the oily meal and ethanol phase, let the ethanol in the oily meal evaporate naturally, and then the feed vegetable protein can be obtained.

Embodiment 3

[0035]Take Jatropha curcas seed kernels after cold pressing and deoiling and pulverize 100g of particles through a 40-mesh sieve, and then dry-steam them at a temperature of 121°C and a pressure of 0.1MPa for 30min; 300ml of industrial ethanol, and ultrasonically oscillate at a power of 150W for 30 minutes, repeat the operation once, filter and separate the oily meal and ethanol phase, let the ethanol in the oily meal dry naturally, and then the feed vegetable protein can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com