Epoxy resin composition and application thereof

A technology of epoxy resin and composition, applied in electrical components, circuits, electrical solid devices, etc., can solve problems such as difficulty in meeting lead-free reflow soldering requirements for high-voltage electrical performance requirements, non-compliance with environmental protection requirements, etc. The effect of high reliability and good molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

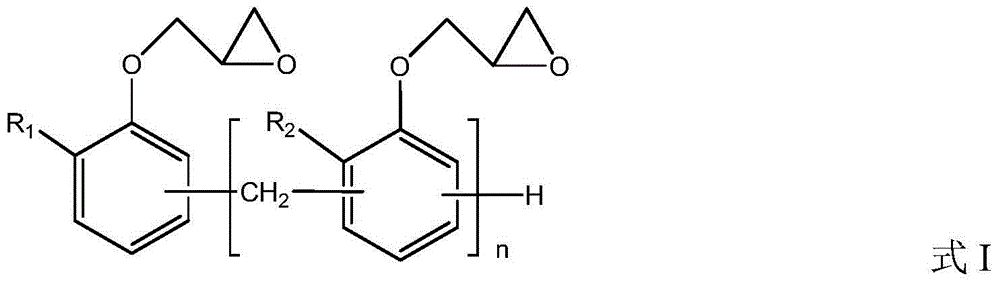

[0042] The formulation of the epoxy resin composition is shown in Table 1. Wherein, in formula I, n=10, and the equivalent ratio of novolak resin to epoxy resin is 1.08.

[0043] The preparation method of the epoxy resin composition is as follows: knead the formula in Table 1 on a twin-screw extruder at 100° C., then cool and pulverize.

Embodiment 2

[0045] The formulation of the epoxy resin composition is shown in Table 1. Wherein, n=12 in formula I, m=10 in formula II, and the equivalent ratio of novolak resin to epoxy resin is 0.89.

[0046] The preparation method of the epoxy resin composition is as follows: knead the formula in Table 1 on a twin-screw extruder at 100° C., then cool and pulverize.

Embodiment 3

[0048] The formulation of the epoxy resin composition is shown in Table 1. Wherein, n=15 in formula I, 1=10 in formula III, and the equivalent ratio of novolak resin to epoxy resin is 0.91.

[0049] The preparation method of the epoxy resin composition is as follows: knead the formula in Table 1 on a twin-screw extruder at 100° C., then cool and pulverize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com