Method for digesting sample in process of measuring chemical oxygen demand (COD)

A chemical oxygen demand and sample technology, which is applied in the preparation of test samples, test water, material inspection products, etc., can solve the problem of high acid consumption, and achieve the effect of low analysis cost and accurate chemical analysis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

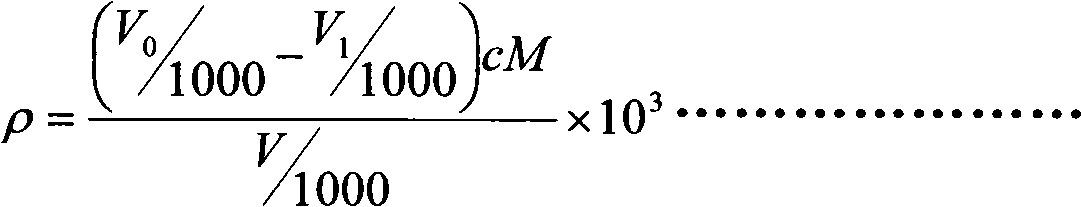

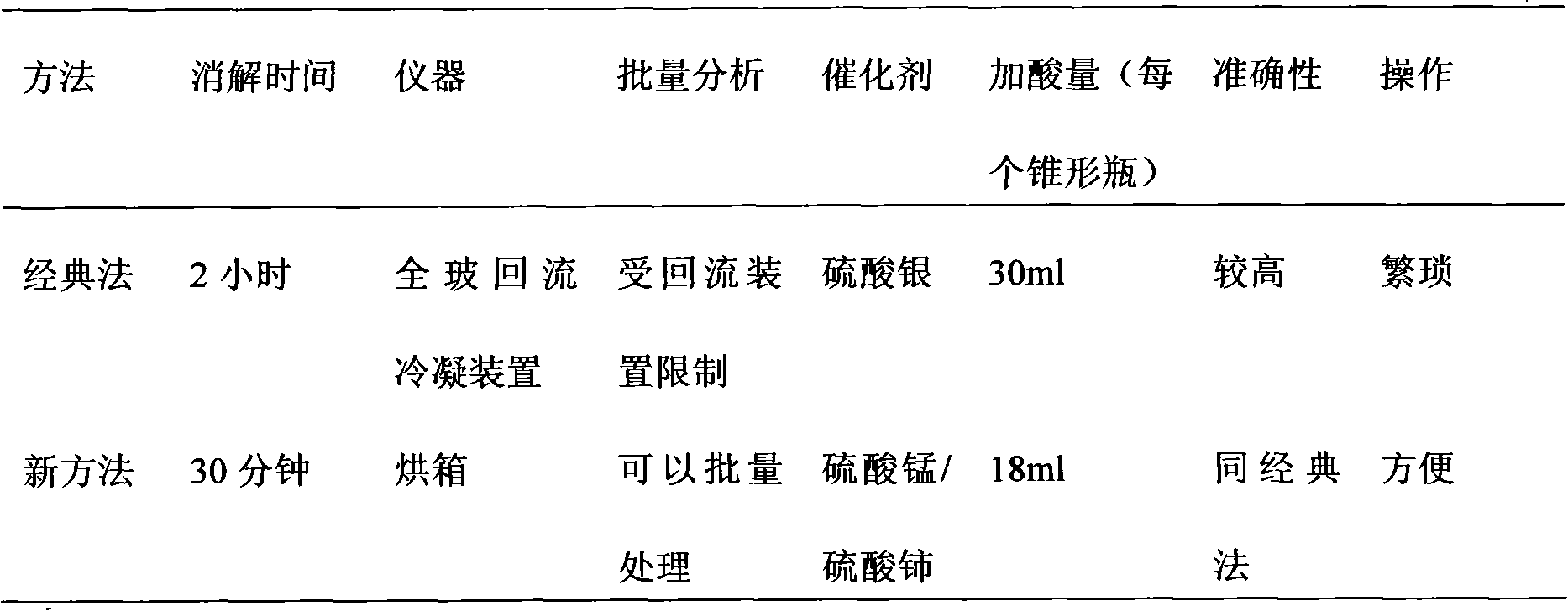

Method used

Image

Examples

Embodiment 1

[0034] (1) Accurately measure 10.00ml of the prepared 50mg / L COD standard sample into the Erlenmeyer flask with a single-marked pipette;

[0035] (2) Accurately measure 5.00ml of potassium dichromate standard solution of 0.0250mol / L in the above-mentioned Erlenmeyer flask with a single-marked pipette;

[0036] (3) Add respectively 3.3ml of manganese sulfate solution of 50g / L with graduated pipette in the above-mentioned conical flask, add 1.0ml of 50g / L cerium sulfate solution;

[0037] (4) Measure 18ml of concentrated sulfuric acid with a graduated cylinder and slowly add it to the above-mentioned triangular flask, shake gently while adding, and cover the bottle mouth with a small petri dish after adding;

[0038] (5) Put the triangular flask in an oven at 160°C, start timing and heating for 30 minutes from the oven temperature of 160°C, stop heating in the oven, turn on the blast, and take the triangular flask out of the oven when the temperature drops slightly.

[0039] (6...

Embodiment 2

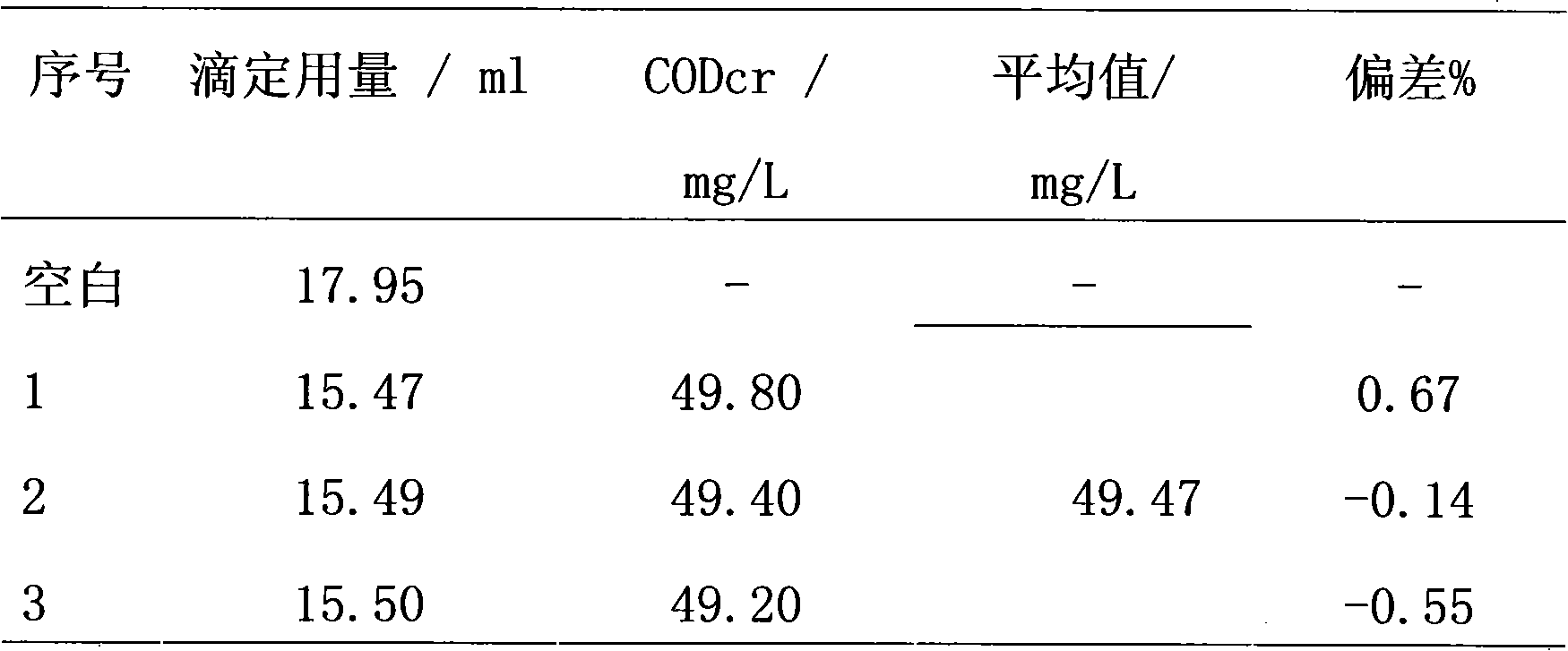

[0046] Determination of the actual water sample in a water purification plant was performed according to the analysis and determination steps described in Example 1. At that time, the calibration concentration of ammonium ferrous sulfate was 0.02505 mol / L, and the calculation results are shown in Table 2.

[0047] Table 2 CODcr measurement results of actual water samples in the factory

[0048] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com