Expandable and cuttable multi-shaft movement control system

A multi-axis motion and control system technology, applied in the field of numerical control, can solve the problems of limited maximum frequency, unfavorable system reliability and speed improvement, limited system performance and reliability, etc., to achieve good flexibility and adaptability, expansion and reduction. The effect of convenient and flexible applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

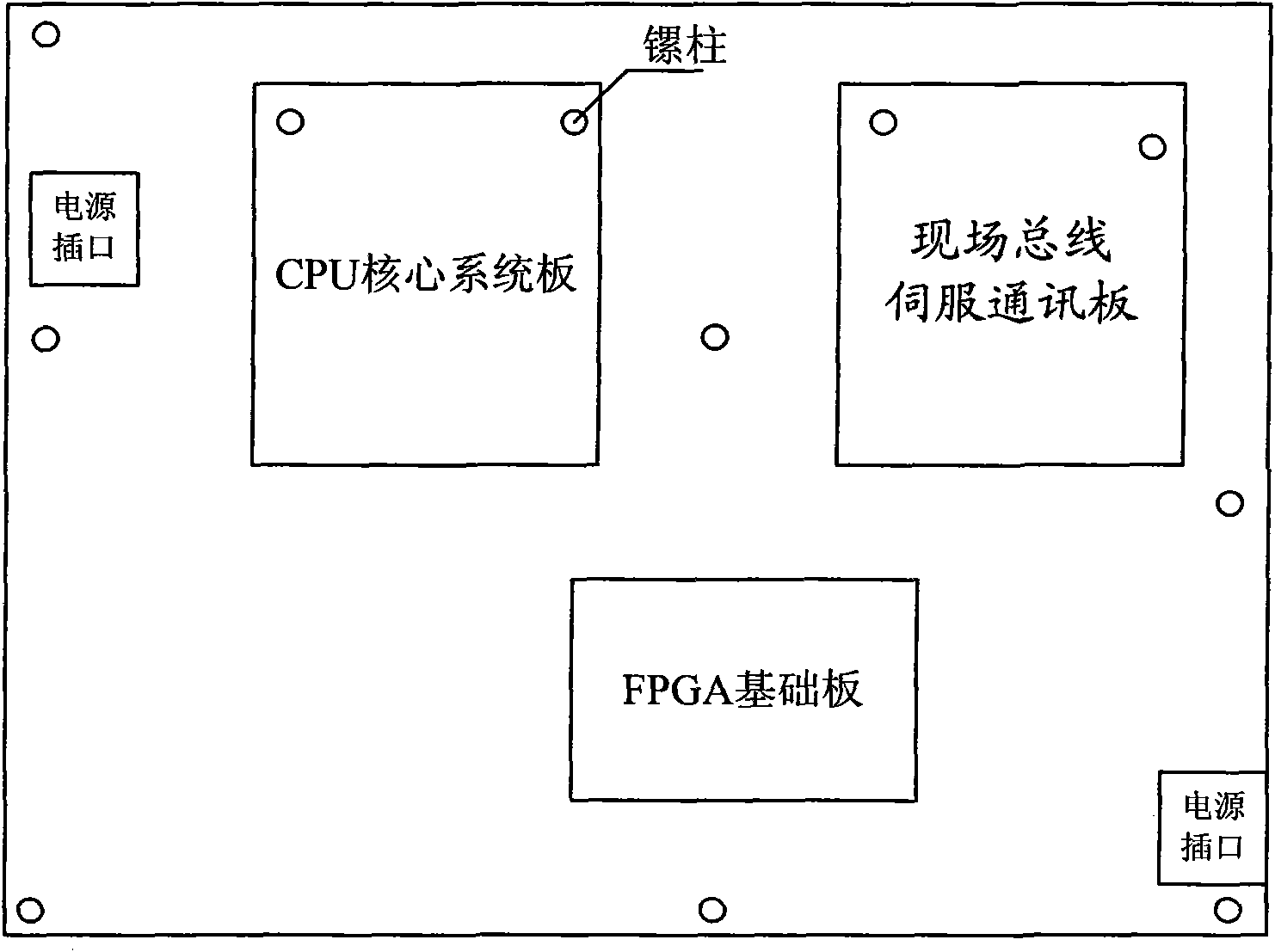

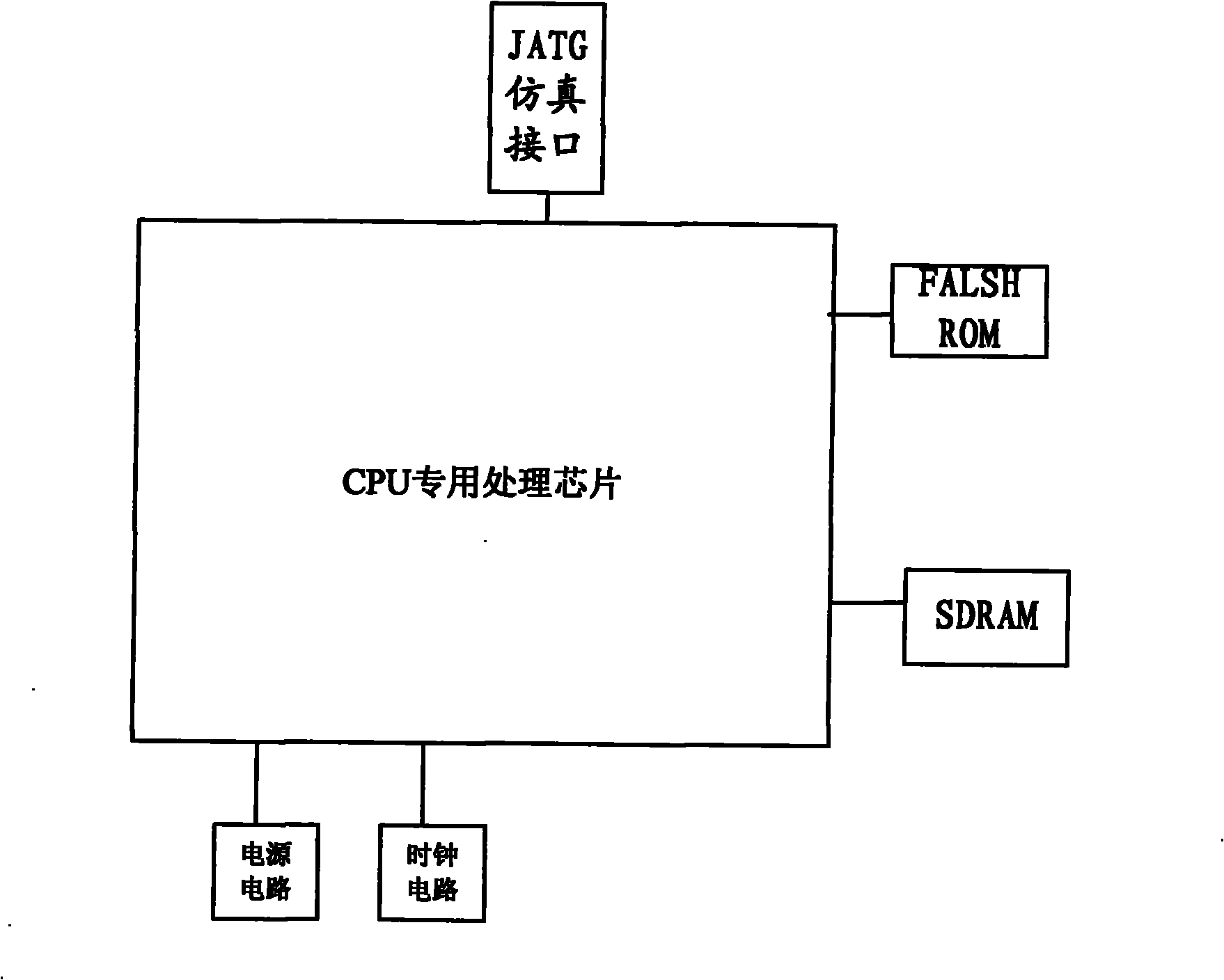

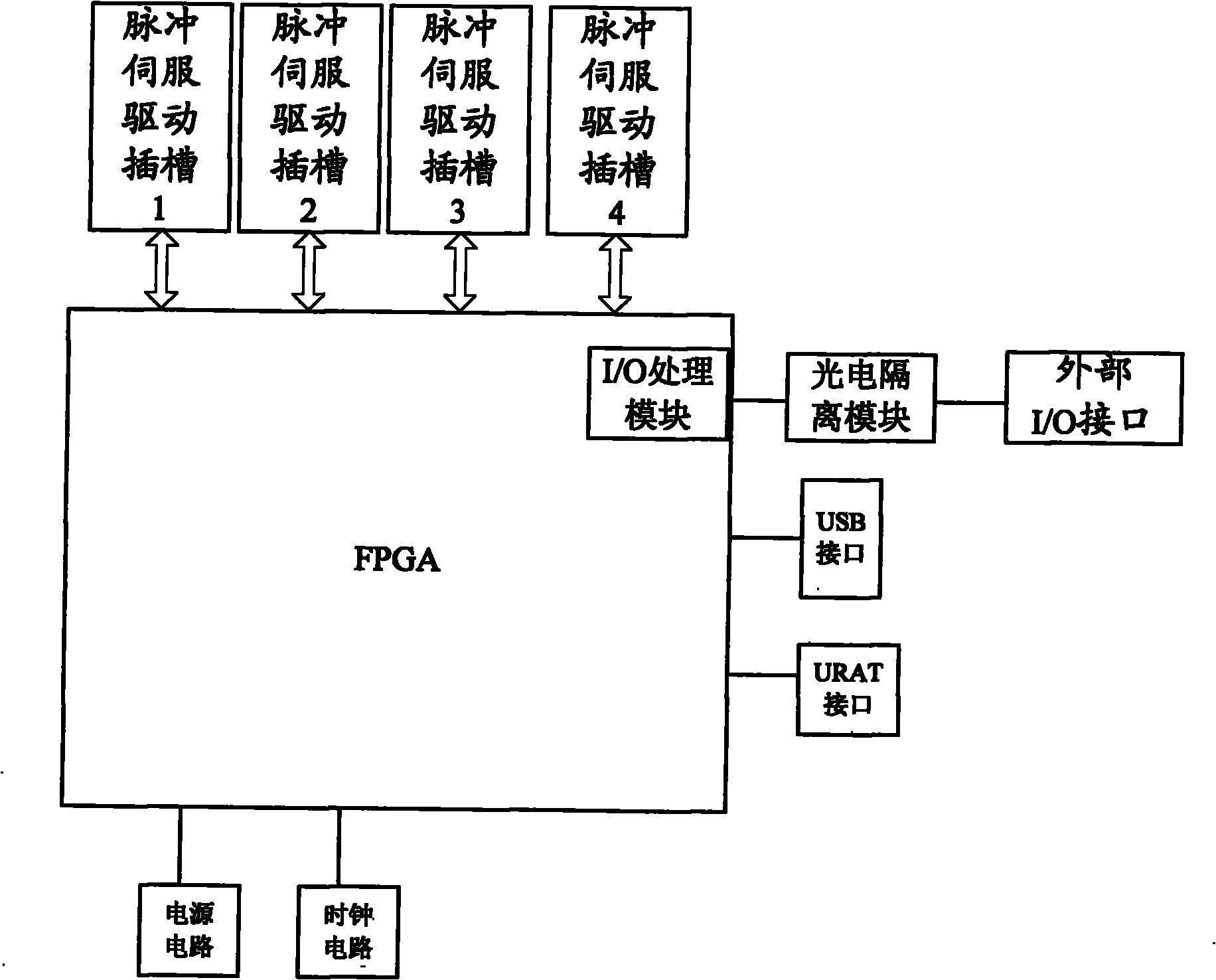

[0043] Such as figure 1 As shown, the scalable and scalable multi-axis motion control system of the present invention is composed of three processing boards, including a CPU core system board, an FPGA base board and a fieldbus servo communication board.

[0044] The CPU core system board and the field bus servo communication board are connected to the FPGA base board through a unified bus slot, and the bus slot is provided with a system internal bus. Specifically, the CPU core system board and the field bus servo communication board are provided with unified slots, and both slots are connected to the FPGA base board through the bus slot at one end of the FPGA base board.

[0045] The FPGA base board, the CPU core system board and the field bus servo communication board are respectively provided with corresponding power circuits, and each power circuit adopts a unified input voltage. The scalable and scalable multi-axis motion control system is equipped with a unified power so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com