Fuel cell cathode catalyst with high stability suitable for dynamic conditions

A high-stability technology for fuel cell cathodes, applied in battery electrodes, catalyst carriers, physical/chemical process catalysts, etc., can solve the problems of low catalyst stability and achieve suitable for large-scale production, high catalyst stability, and conditions easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix the raw material MWNTs (diameter: 8nm) with concentrated nitric acid (65-68%) at a ratio of 1g:100mL, treat with ultrasonic waves for 15min, then reflux at 120°C for 4h, cool to room temperature, filter, and wash the solid with distilled water several times To neutral, dry overnight at 80°C in a vacuum oven.

[0037] The carbon nanotube-supported platinum catalyst was prepared by intermittent microwave heating method, specifically: firstly, the treated MWNTs and ethylene glycol were mixed and ultrasonically stirred until uniform, and then an appropriate amount of H 2 PtCl 6The solution was ultrasonically stirred, and finally the pH value was adjusted to pH>12 with NaOH in ethylene glycol solution. Then heat it in a household microwave oven, cool it to room temperature, add dilute hydrochloric acid to adjust the pH value to pH<2, and after centrifugal washing to no chloride ion, vacuum dry it in a vacuum oven at 80°C overnight. The loading of Pt was 20%.

[0038] ...

Embodiment 2

[0040] Mix the raw material MWNTs (diameter: 10-20nm) with concentrated nitric acid (65-68%) at a ratio of 1g:100mL, treat with ultrasonic waves for 15min, then reflux at 120°C for 4h, cool to room temperature, filter, and wash the solid with distilled water Multiple times to neutral, dry overnight at 80°C in a vacuum oven.

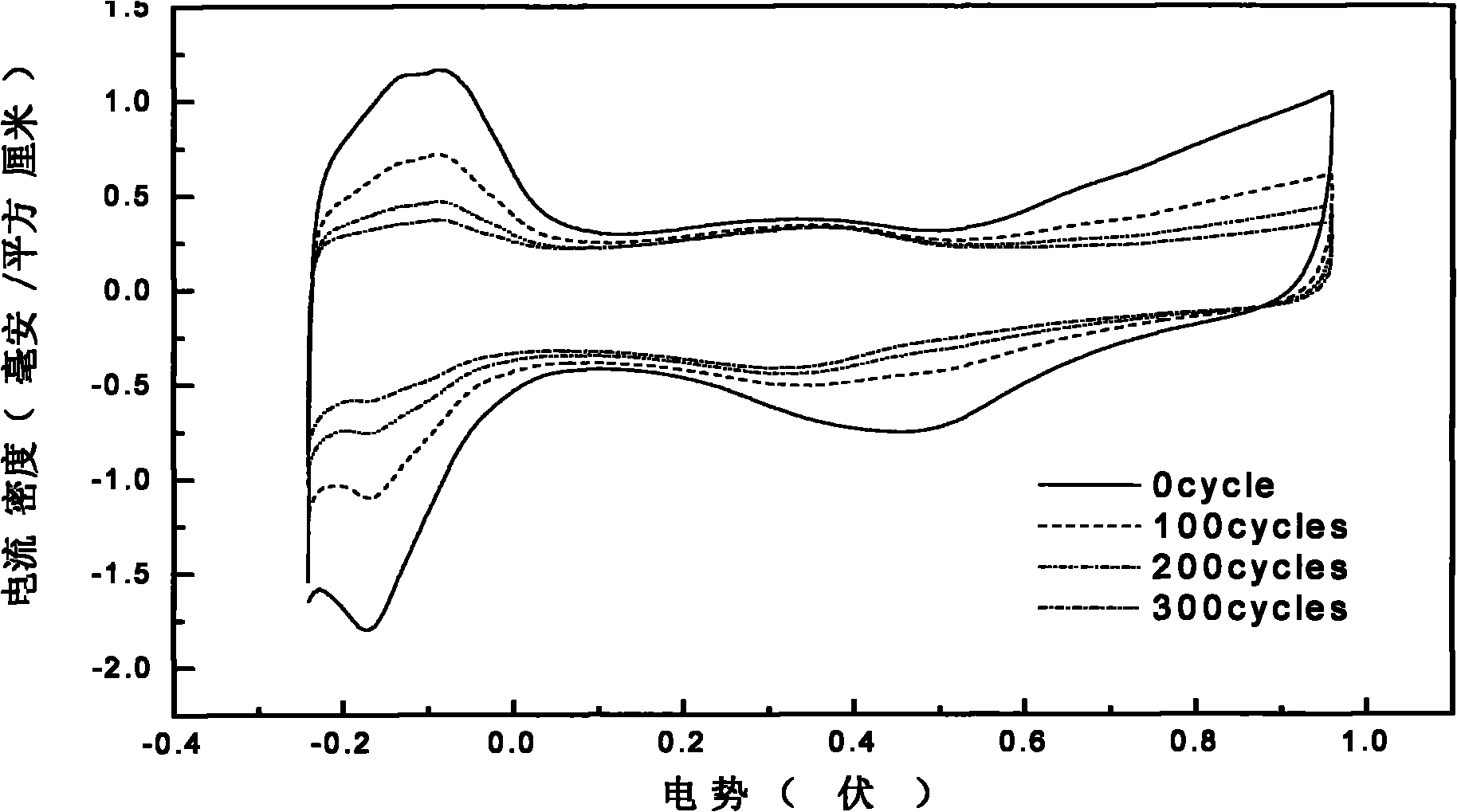

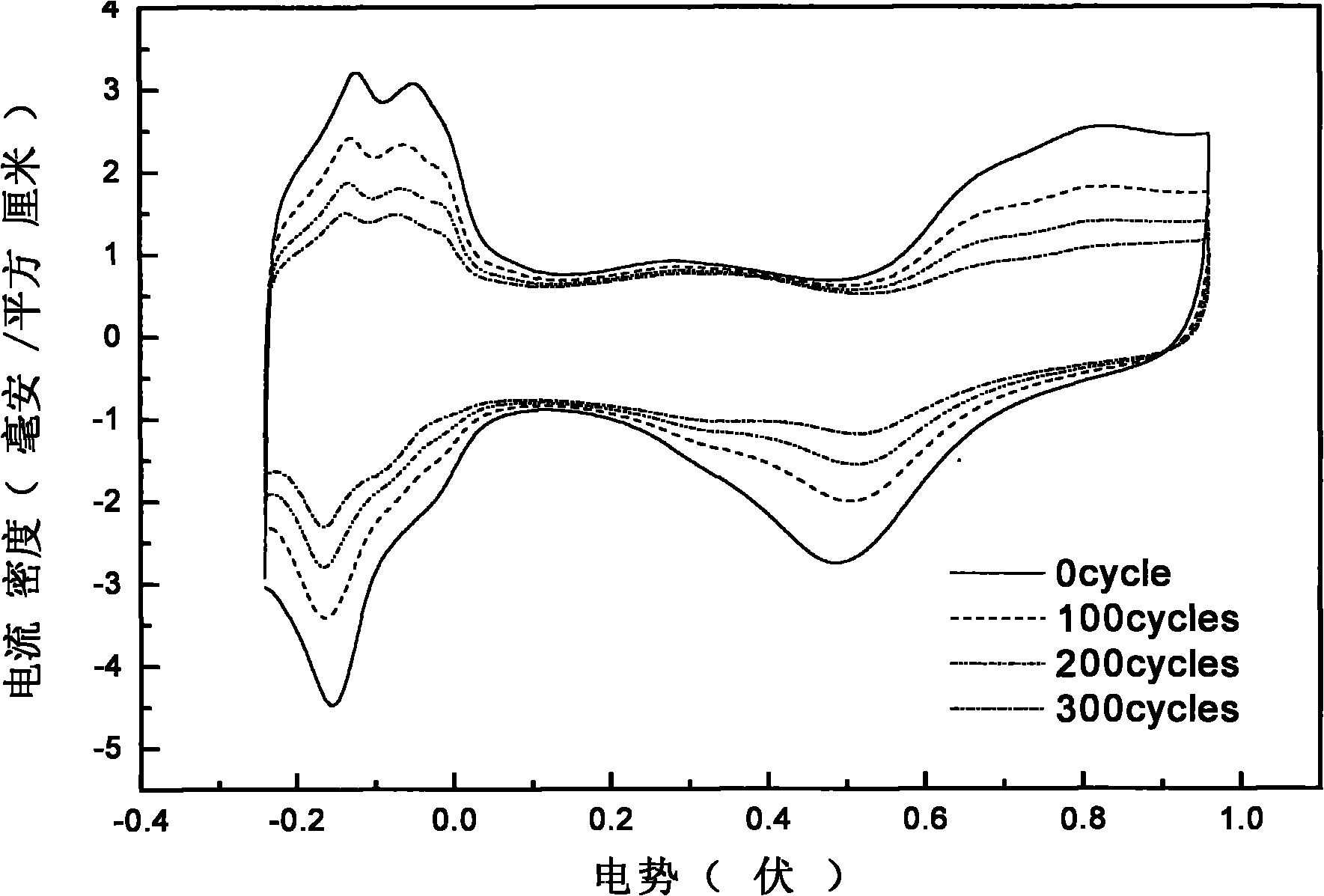

[0041] The carbon nanotube-supported platinum catalyst was prepared by intermittent microwave heating method, specifically: firstly, the treated MWNTs and ethylene glycol were mixed and ultrasonically stirred until uniform, and then an appropriate amount of H 2 PtCl 6 The solution was ultrasonically stirred, and finally the pH value was adjusted to pH>12 with NaOH in ethylene glycol solution. Then heat it in a household microwave oven, cool it to room temperature, add dilute hydrochloric acid to adjust the pH value to pH figure 2 , 5 It is the CV and ORR diagrams before and after 300 scans of the catalyst prepared from the treated carbon nanotubes in th...

Embodiment 3

[0043] Mix the raw material MWNTs (diameter: 30-50nm) with concentrated nitric acid (65-68%) at a ratio of 1g:100mL, treat with ultrasonic waves for 15min, then reflux at 120°C for 4h, cool to room temperature, filter, and wash the solid with distilled water Multiple times to neutral, dry overnight at 80°C in a vacuum oven.

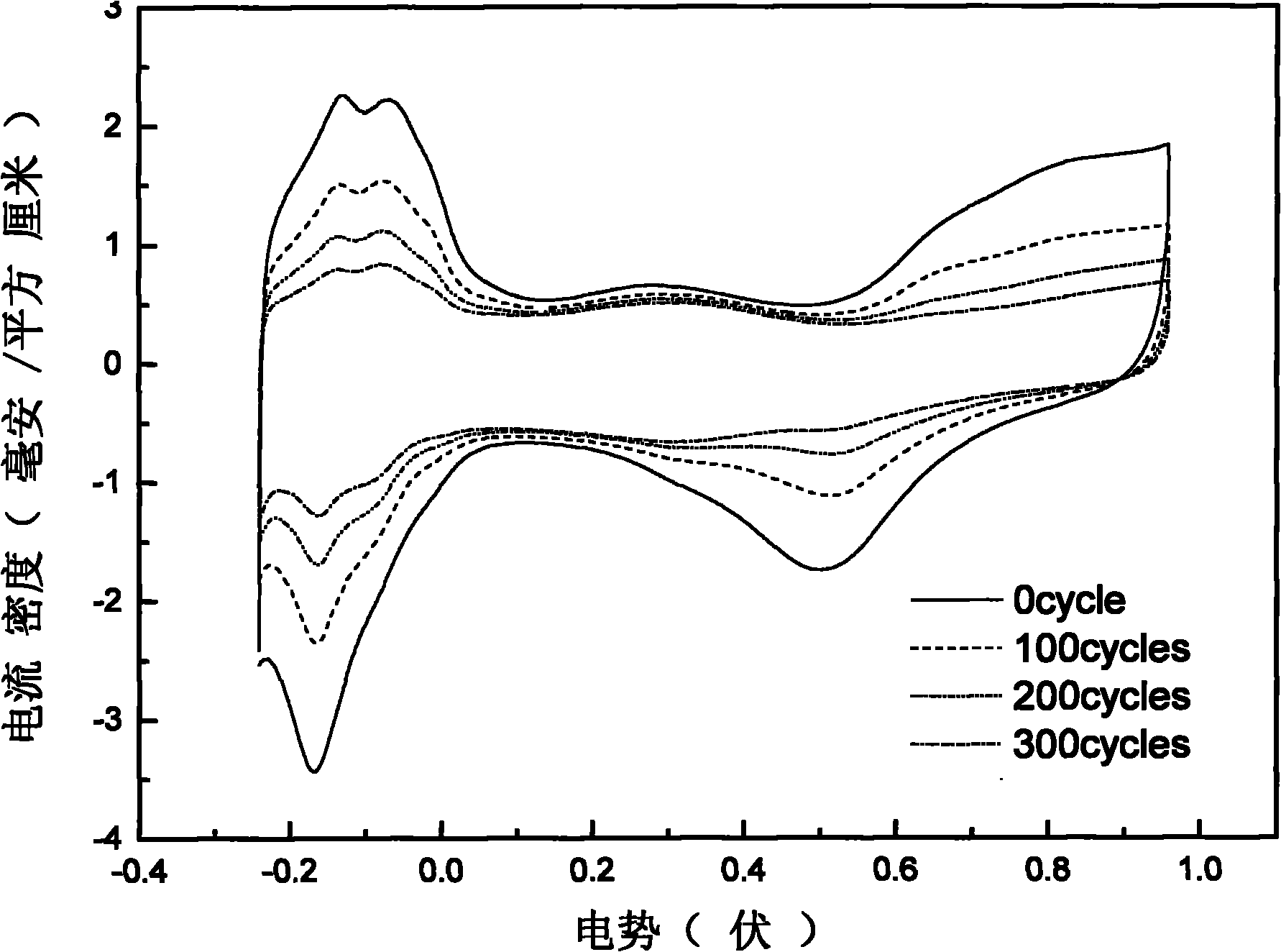

[0044] The carbon nanotube-supported platinum catalyst was prepared by intermittent microwave heating method, specifically: firstly, the treated MWNTs and ethylene glycol were mixed and ultrasonically stirred until uniform, and then an appropriate amount of H 2 PtCl 6 The solution was ultrasonically stirred, and finally the pH value was adjusted to pH>12 with NaOH in ethylene glycol solution. Then heat it in a household microwave oven, cool it to room temperature, add dilute hydrochloric acid to adjust the pH value to pH image 3 , 6 It is the CV and ORR diagrams before and after 300 scans of the catalyst prepared from the treated carbon nanotubes in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com