Method for removing NOX in flue gas

A technology of nitrogen oxides and flue gas, applied in the field of environmental pollution control, can solve the problems of secondary pollution, low denitrification efficiency, and few, etc., to improve the mixing degree, reduce the ammonia escape rate, improve the utilization rate and denitrification efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for removing nitrogen oxides in flue gas, which is to remove NO in flue gas by using ammonia or urea as a reducing agent X Reduction: The ammonia or urea solution is transported through water vapor and sprayed into the furnace.

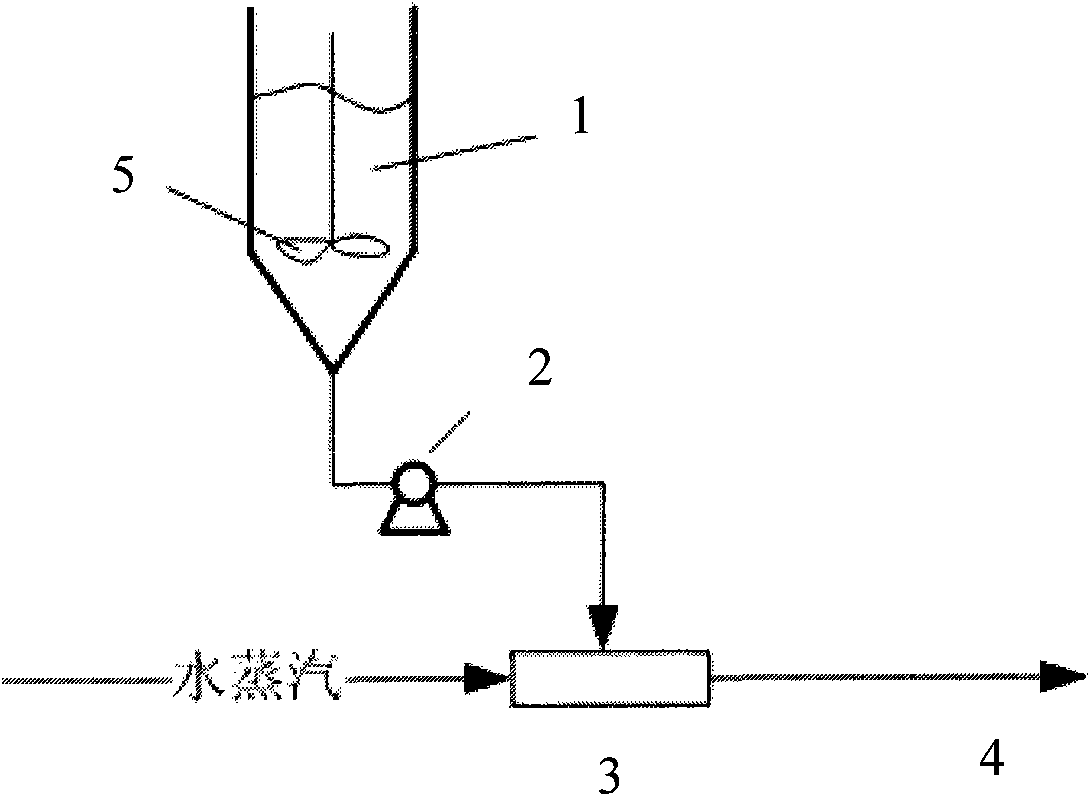

[0038] Such as figure 1 As shown, the urea solution or ammonia solution 1 is delivered to the conveyor 3 through the metering pump 2, and the water vapor is delivered through the conveyor 3, mixed with the water vapor in the conveyor, and sprayed into the furnace. 4 within. A stirrer 5 is provided in the urea solution or ammonia solution.

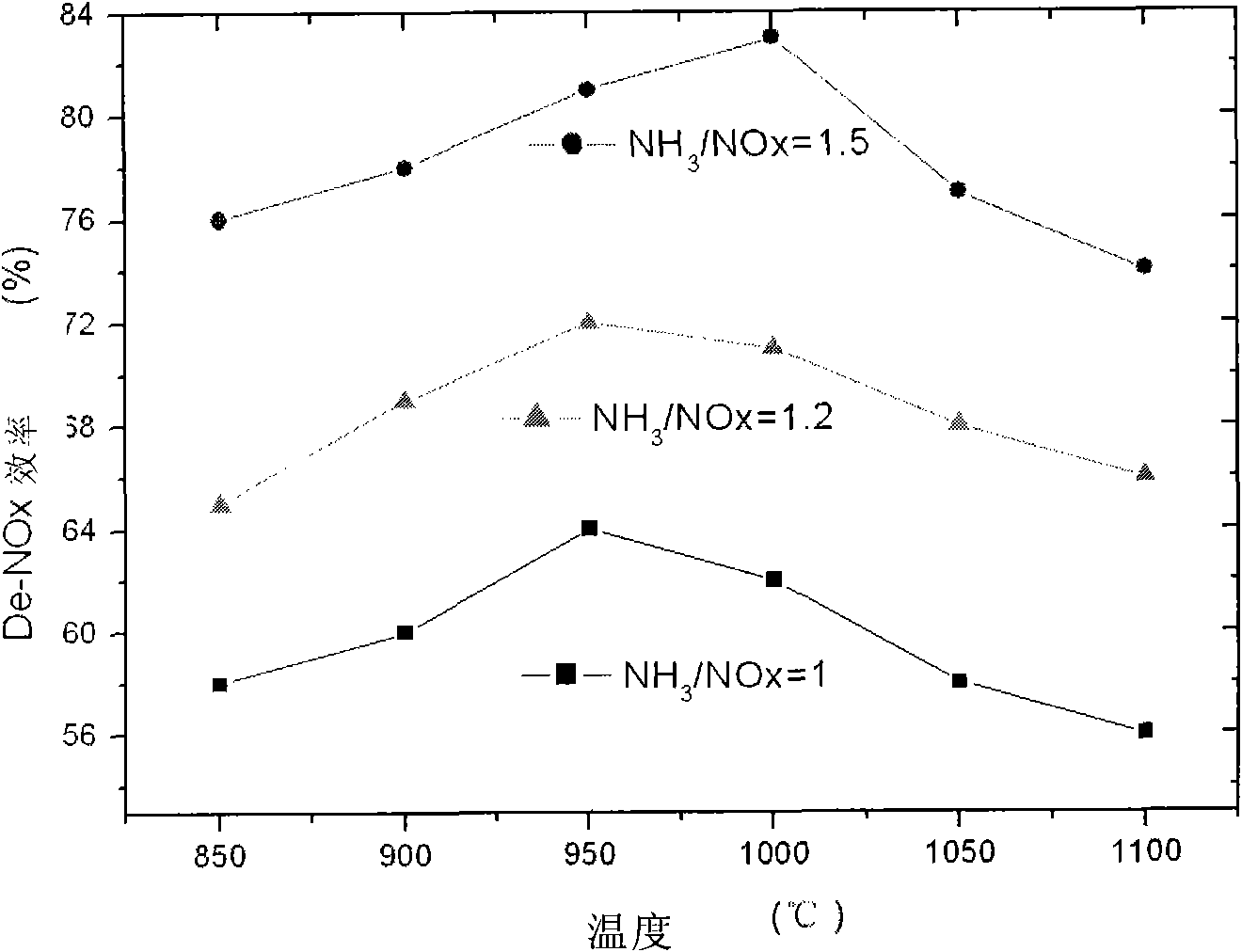

[0039] When urea is used as the reducing agent, the urea solution is generally about 10% to ensure that the moisture content in the flue gas is within the range of 6-10%. 3 The / NOx molar ratio is 1.2-1.5 (determined according to the efficiency of removing NOx), the boiler waste heat steam at 150-300°C is used to spray the urea solution into the boiler furnace, and the weight ratio of steam to urea solut...

Embodiment 2

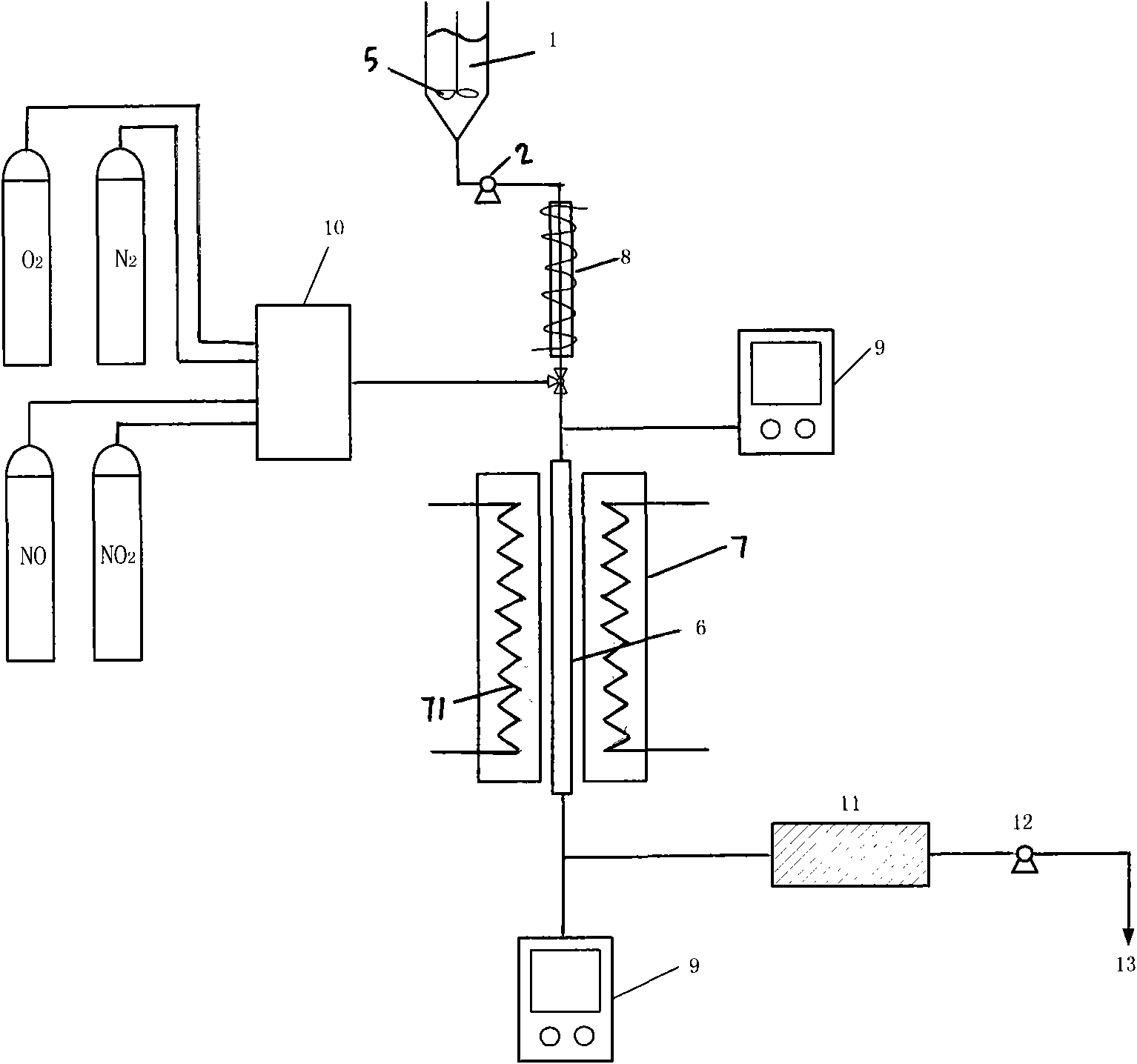

[0042] Example 2 Denitration simulation experiment

[0043] SNCR denitrification device with simulated flue gas volume of 6L / min, such as figure 2 Shown. The quartz glass SNCR reaction tube 6 with an inner diameter of 30mm and a length of 760mm has a wall thickness of 2mm. The SNCR reaction tube 6 is heated to a maximum of 1300°C by the tubular electric furnace 7 (the tubular electric furnace 7 is equipped with heating resistance wires 71). A program controller 8 adjusts the simulated flue gas temperature, and uses the urea solution 1 as the denitration reducing agent. Control the amount of water vapor for denitrification by changing the concentration of the urea solution and the injection amount, and the NOx concentration of the simulated flue gas is 500mg / Nm 3 . The urea solution is pumped into the simulated flue gas through the metering pump 2 and heated by the program controller 8 into the reaction tube. The reaction system is also provided with a flue gas analyzer 9, a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com