Preparation method of wear-resistant coating on inner wall of cylinder of twin-screw extruder

A twin-screw extrusion and wear-resistant coating technology, applied in the field of plastic machinery manufacturing, can solve problems such as residual plastic at seams, and achieve the effects of easy operation, low cost of preparation process and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

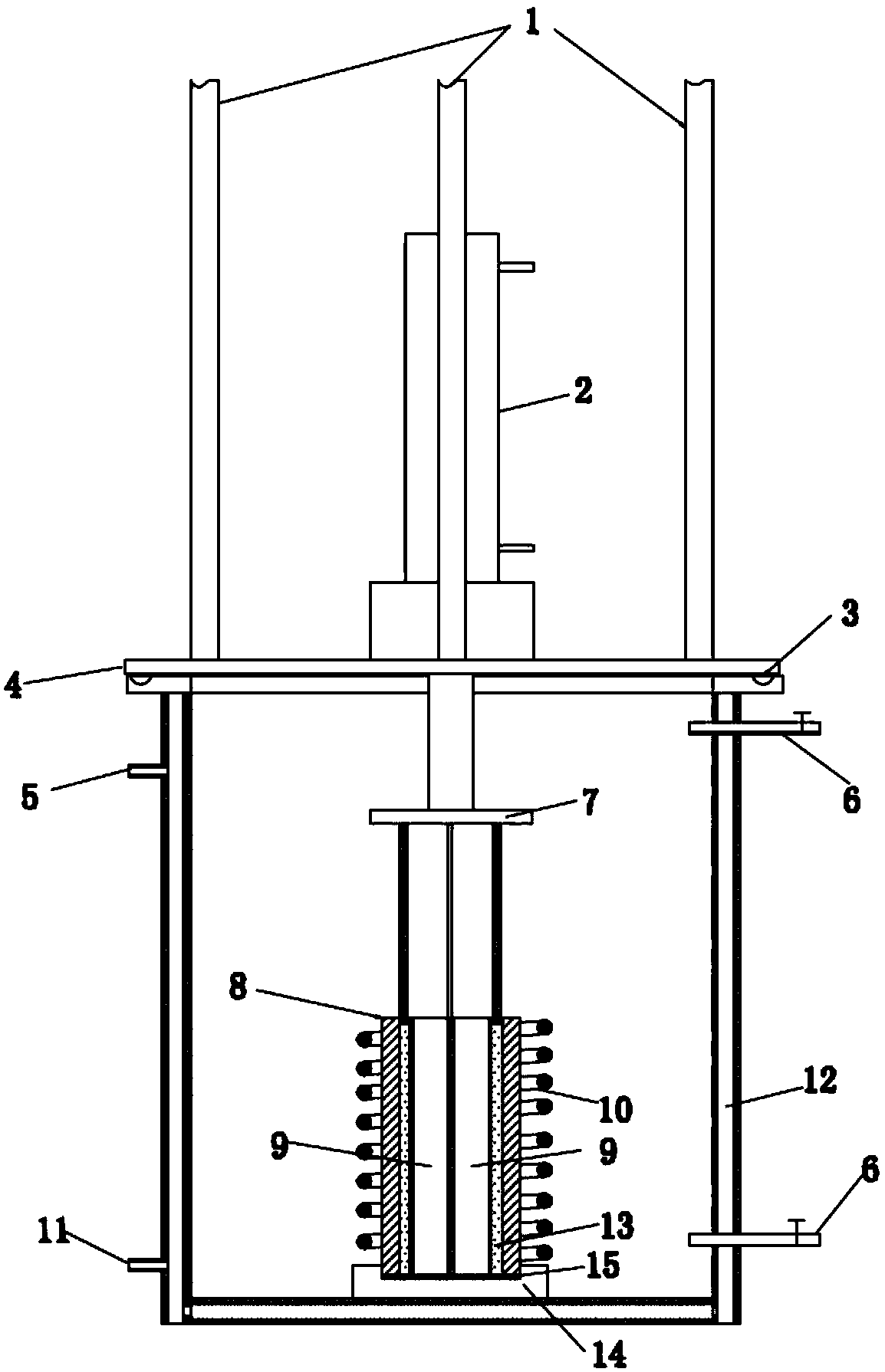

[0043] A method for preparing a wear-resistant coating on the inner wall of a twin-screw extruder barrel:

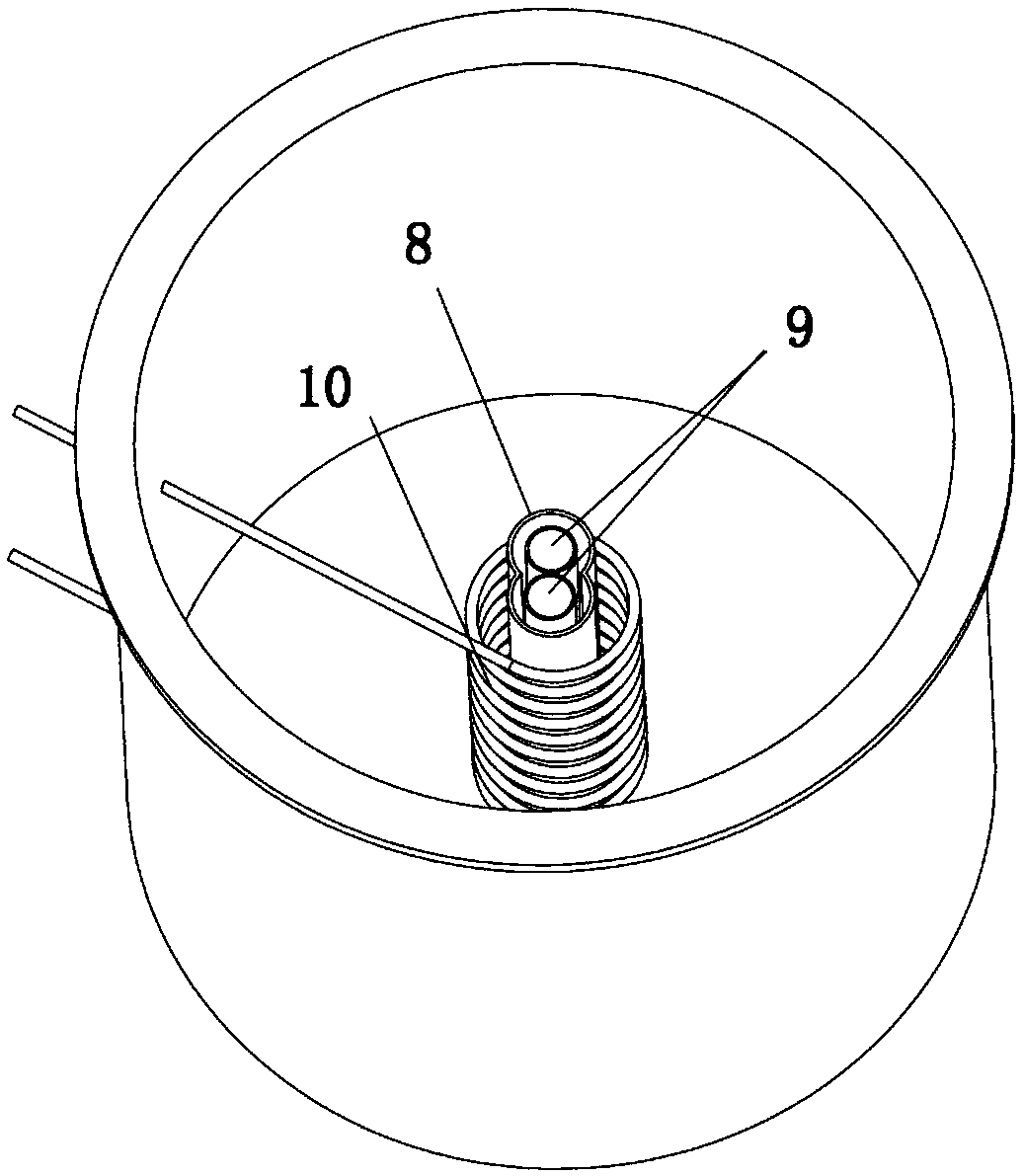

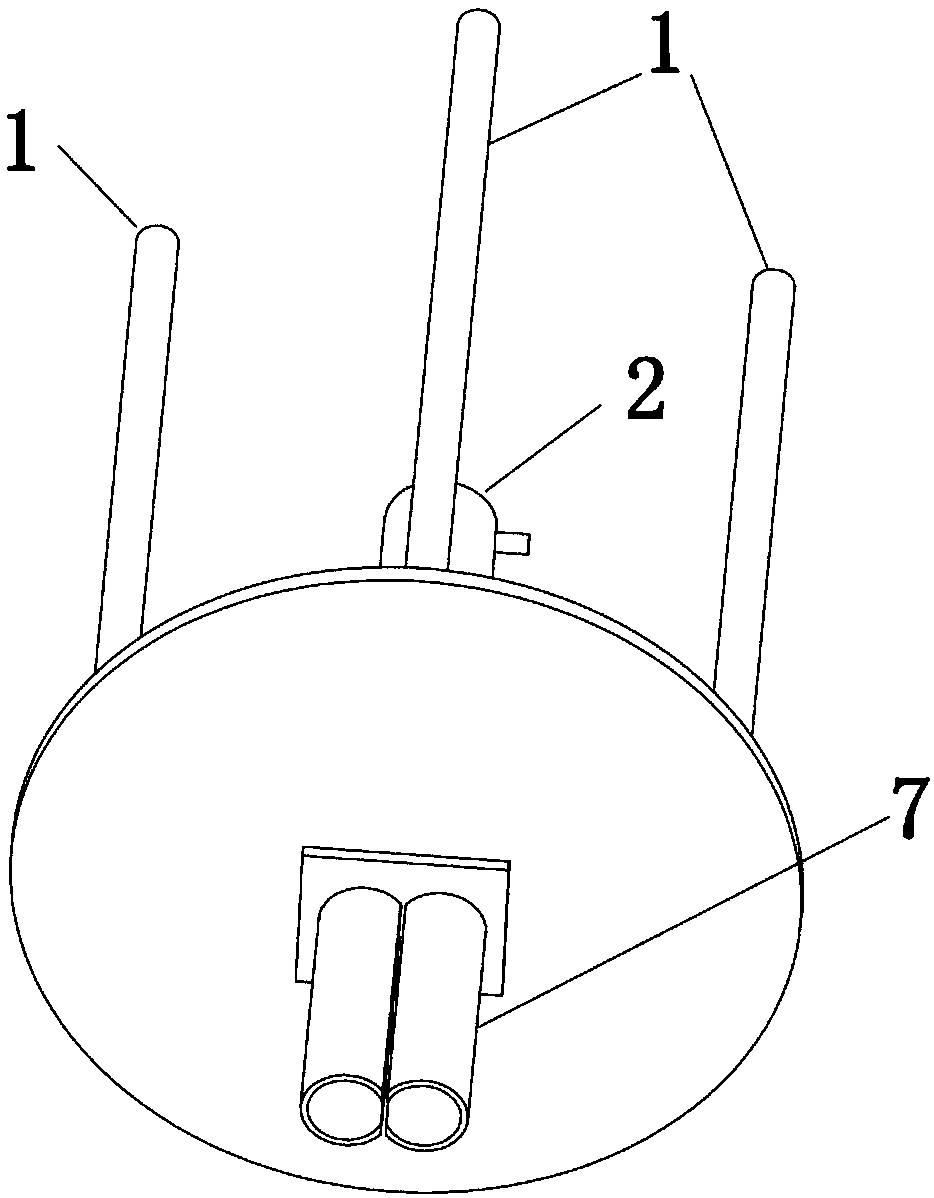

[0044] Step 1. Use a double-hole steel cylinder as the barrel jacket 8 of the twin-screw extruder. The outer diameter of the double holes is 70mm, and the wall thickness is 10mm. The inner wall of the barrel jacket 8 is derusted and degreased, and the center distance between the two holes is measured. ;

[0045] Step 2, take a steel plate 15 with a thickness of 10mm, take two steel pipes 9 with an outer diameter of 42mm, and have a wall thickness of 2mm, and seamlessly weld the bottoms of the two steel pipes 9 on the steel plate 15, so that the distance between the centers of the two steel pipes 9 is equal to the above-mentioned The center-to-center distance of the cylinder jacket 8 double holes;

[0046] Step 3, nesting the two steel pipes 9 in the cylinder jacket 8, and seamlessly welding the bottom of the cylinder jacket 8 on the steel plate 15, so that the two steel...

Embodiment 2

[0053] A method for preparing a wear-resistant coating on the inner wall of a twin-screw extruder barrel:

[0054] Step 1. Adopt a double-hole steel cylinder as the casing 8 of the twin-screw extruder. The outer diameter of the double holes is 90mm and the wall thickness is 15mm. The inner wall of the casing 8 is derusted and degreased, and the center distance between the two holes is measured. ;

[0055] Step 2, take a steel plate 15 with a thickness of 10mm, take two steel pipes 9 with an outer diameter of 50mm, and have a wall thickness of 3mm, and seamlessly weld the bottoms of the two steel pipes 9 on the steel plate 15, so that the distance between the centers of the two steel pipes 9 is equal to the above-mentioned The center-to-center distance of the cylinder jacket 8 double holes;

[0056] Step 3, nesting the two steel pipes 9 in the cylinder jacket 8, and seamlessly welding the bottom of the cylinder jacket 8 on the steel plate 15, so that the two steel pipes 9 are ...

Embodiment 3

[0062] A method for preparing a wear-resistant coating on the inner wall of a twin-screw extruder barrel:

[0063] Step 1. Use a double-hole steel cylinder as the barrel jacket 8 of the twin-screw extruder. The outer diameter of the double holes is 110 mm, and the wall thickness is 20 mm. The inner wall of the barrel jacket 8 is derusted and degreased, and the center distance between the two holes is measured. ;

[0064] Step 2, take a steel plate 15 with a thickness of 10mm, take two steel pipes 9 with an outer diameter of 56mm, and have a wall thickness of 4mm, and seamlessly weld the bottoms of the two steel pipes 9 on the steel plate 15, so that the distance between the centers of the two steel pipes 9 is equal to the above-mentioned The center-to-center distance of the cylinder jacket 8 double holes;

[0065] Step 3, nesting the two steel pipes 9 in the cylinder jacket 8, and seamlessly welding the bottom of the cylinder jacket 8 on the steel plate 15, so that the two st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com