Wood fiber reinforced flame retardant foam composite plate and manufacturing method thereof

A wood fiber and flame retardant foam technology is applied in the field of wood fiber reinforced flame retardant foam composite panels, which can solve the problems of low cost, high cost, high toxicity, etc., and achieves good flame retardancy, improved compression resistance, and low toxic release. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

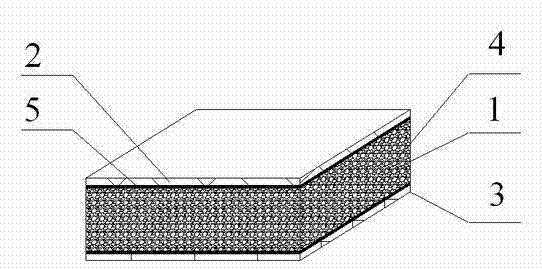

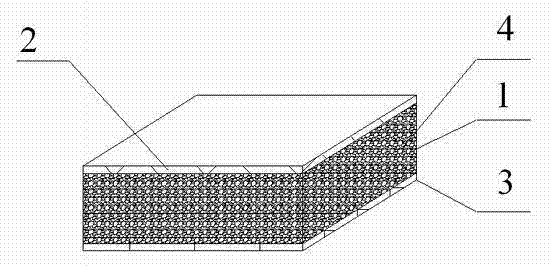

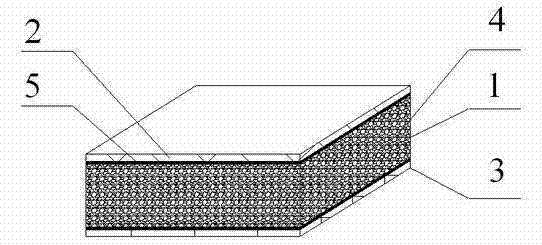

Image

Examples

Embodiment 1

[0033] Step 1: Preparation of wood fiber-reinforced flame-retardant foam material First, add 0.25 parts of γ-aminopropyltriethoxysilane coupling agent to the wood fiber, stir evenly, and dry at 60° C. for use. Then get 60 parts of phenolic resin, then add 6 parts of phosphoric acid curing agent, 2 parts of nitrile rubber, 4 parts of cyclopentane foaming agent and 28 parts of wood fiber after coupling agent treatment. Put the mixture in a kneader at room temperature and knead evenly, then take it out and place it in a foaming mold at 70°C for foaming and solidification.

[0034] Step 2: Preparation of Wood Fiber Reinforced Flame Retardant Foam Composite Sheets

[0035] Cut the foam material obtained in the first step into a certain shape, coat the upper and lower sides with a certain quality of white latex respectively, use a 2mm thick single-layer wood board for the upper and lower panels, and coat the contact surfaces of the wood board and the foam material with a certain qua...

Embodiment 2

[0037] Step 1: Preparation of Wood Fiber Reinforced Flame Retardant Foam

[0038] First, add 0.5 parts of coupling agent γ-chloropropyltriethoxysilane to the wood fiber, stir evenly, and then dry at 60°C. Then take a certain amount of melamine-modified urea-formaldehyde resin, then add successively, then take 55 parts of phenolic resin, then add 10 parts of p-toluenesulfonic acid curing agent, 5 parts of nitrile rubber, and 10 parts of cyclopentane blowing agent And 20 parts of wood fiber after coupling agent treatment. Put the mixture in a kneader at room temperature and knead evenly, then take it out and place it in a foaming mold at 70°C for foaming and solidification.

[0039] Step 2: Preparation of Wood Fiber Reinforced Flame Retardant Foam Composite Sheets

[0040] Cut the foam material obtained in the first step into a certain shape, coat the upper and lower sides with a certain quality of phenolic glue, use 4mm thick high-density flame-retardant plates for the upper ...

Embodiment 3

[0042] Step 1: Preparation of Wood Fiber Reinforced Flame Retardant Foam

[0043] First, add 0.5 parts of coupling agent γ-chloropropyltriethoxysilane to the wood fiber, stir evenly, and then dry at 60°C. Then take a certain amount of melamine-modified urea-formaldehyde resin, then add 75 parts of phenolic resin in turn, then add 9 parts of p-toluenesulfonic acid curing agent, 3 parts of nitrile rubber, and 4 parts of cyclopentane blowing agent And 9 parts of wood fiber after coupling agent treatment. Put the mixture in a kneader at room temperature and knead evenly, then take it out and place it in a foaming mold at 70°C for foaming and solidification.

[0044] Step 2: Preparation of Wood Fiber Reinforced Flame Retardant Foam Composite Sheets

[0045] Cut the foam material obtained in the first step into a certain shape, and coat the upper and lower sides with a certain quality of urea-formaldehyde glue respectively. The upper and lower panels are made of 0.5mm thick high-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flat compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com