Method for injecting high-volatile bituminous coal into blast furnace

A blast furnace coal injection and bituminous coal separation technology, applied in the field of blast furnace coal injection, can solve the problem that the overall coal volume cannot be increased, and achieve the effect of improving product competitiveness and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

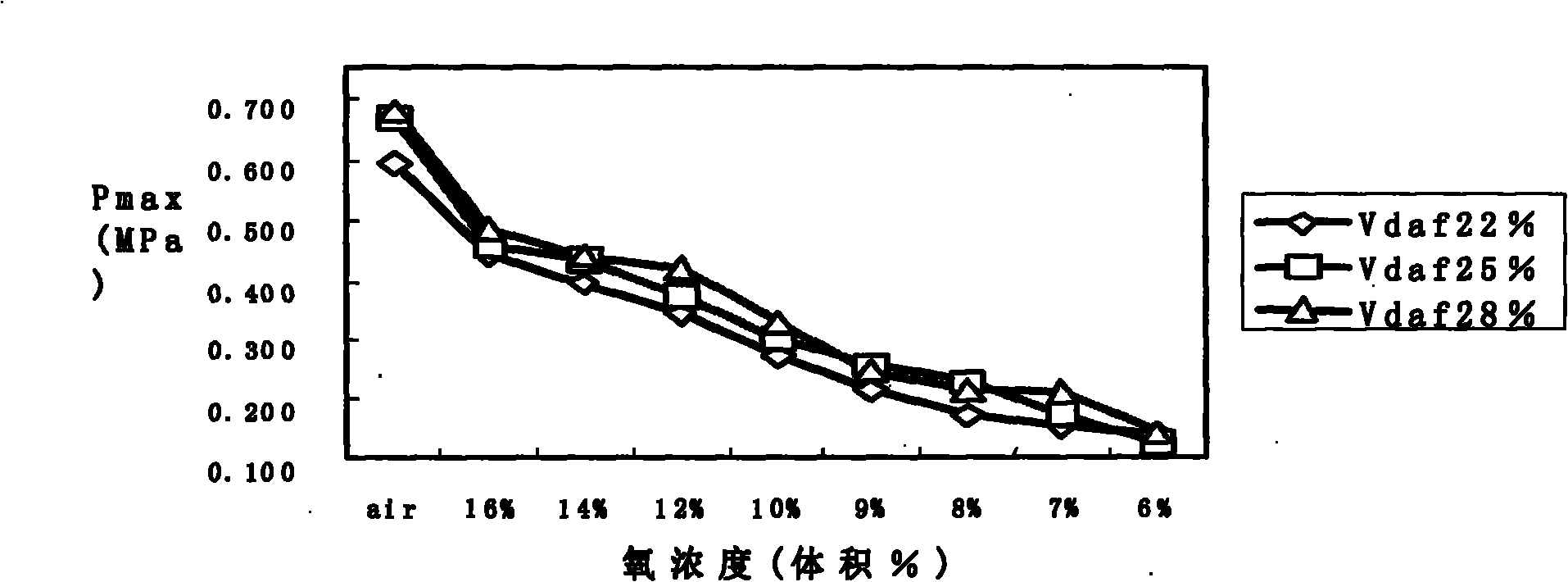

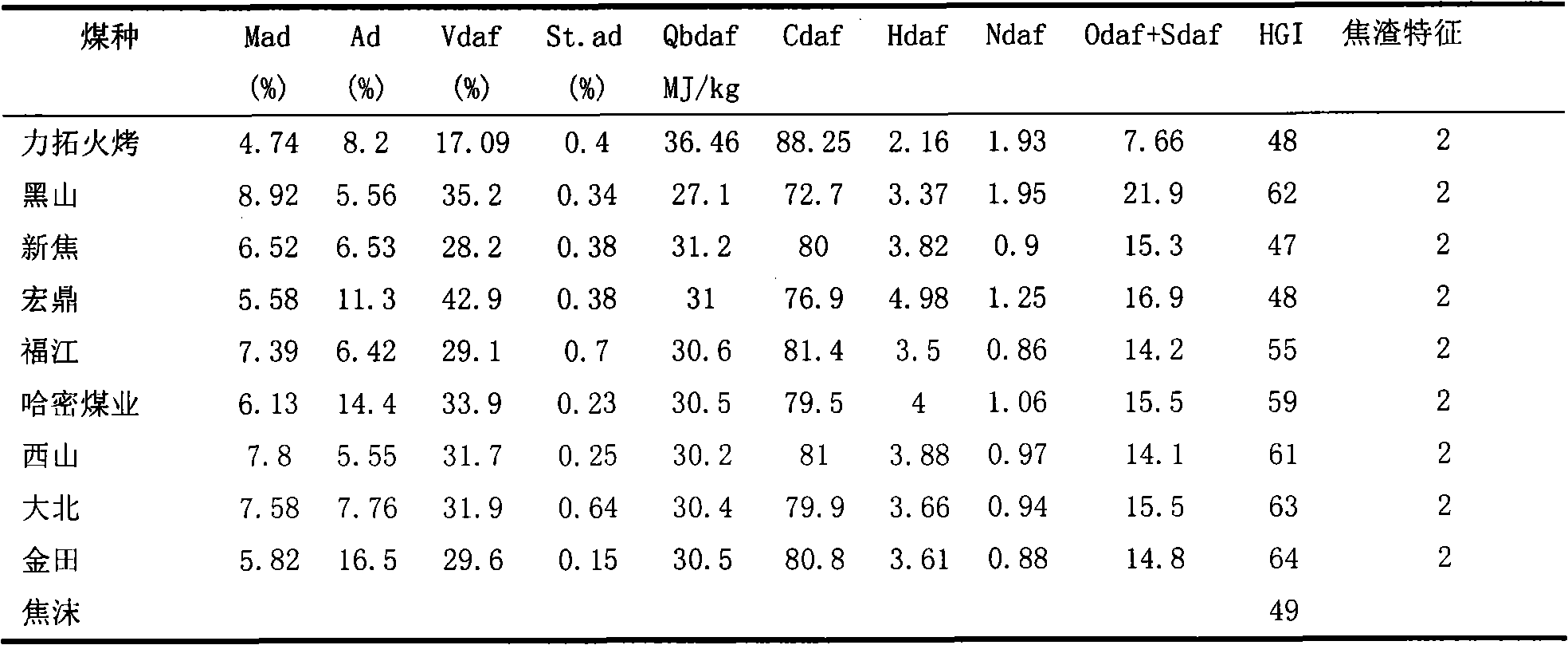

[0100]A method of using high-volatile bituminous coal for blast furnace coal injection, when the temperature at the inlet of the mill is equal to 320 degrees, the oxygen content at the outlet of the bag is equal to 4%, the oxygen content at the entrance of the mill is equal to 3%, and the oxygen content in the flue gas is equal to 2%. Under the condition that the carbon monoxide content in the pulverized coal bunker is equal to 2000PPm and the temperature of the pulverized coal is equal to 70 degrees, the volatile content of the pulverized coal injected into the blast furnace is equal to 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com