Preparation method of ultrahigh molecular weight polyethylene (UHMWPE) short fibers

A technology of ultra-high molecular weight and polyethylene, which is applied to the types of furnaces, lighting and heating equipment, drying, etc., and can solve problems such as differences in mechanical properties and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention discloses a method for preparing ultra-high molecular weight polyethylene short fibers, including:

[0027] Preheating: Preheat the ultra-high molecular weight polyethylene long fibers at 40°C to 60°C;

[0028] Crimping: mechanically crimping the preheated ultra-high molecular weight polyethylene long fibers;

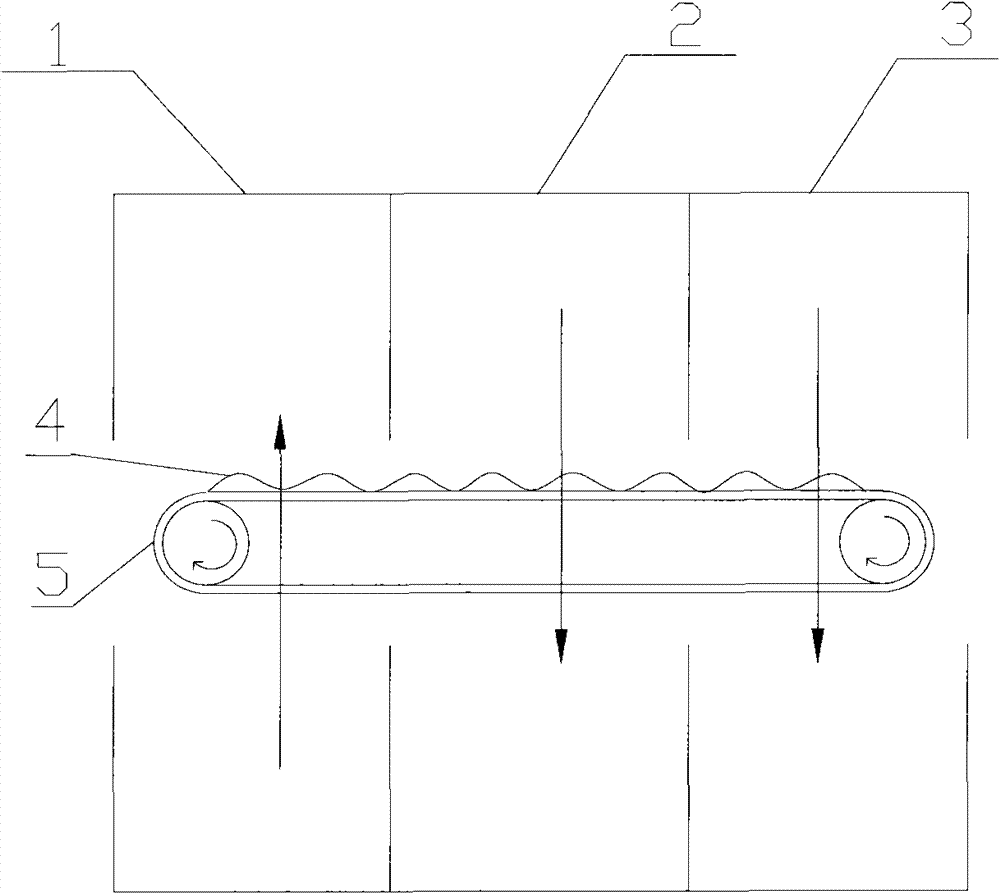

[0029] Drying: The crimped ultra-high molecular weight polyethylene long fibers are sequentially subjected to first-stage drying, second-stage drying, and third-stage drying. In the first-stage drying, the hot air direction is from above the ultra-high molecular weight polyethylene long fibers Blowing downwards, in the third stage drying, the direction of the hot air is blowing downwards from above the ultra-high molecular weight polyethylene long fibers;

[0030] Cutting: Cut the dried ultra-high molecular weight polyethylene long fibers into short fibers of 50mm-100mm.

[0031] For the spinning method of UHMWPE, fibers ...

Embodiment 1

[0048] 1. The fibers spread evenly

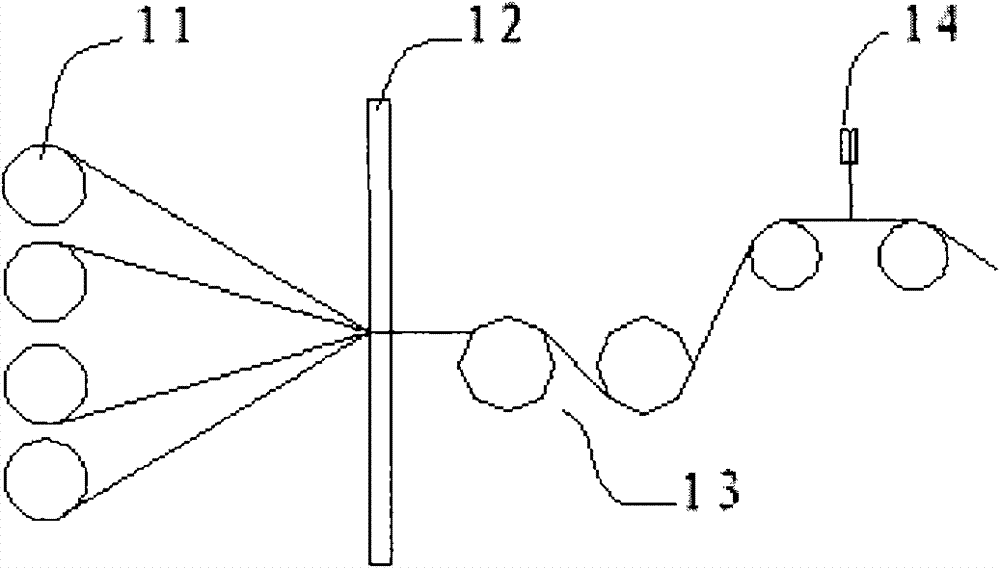

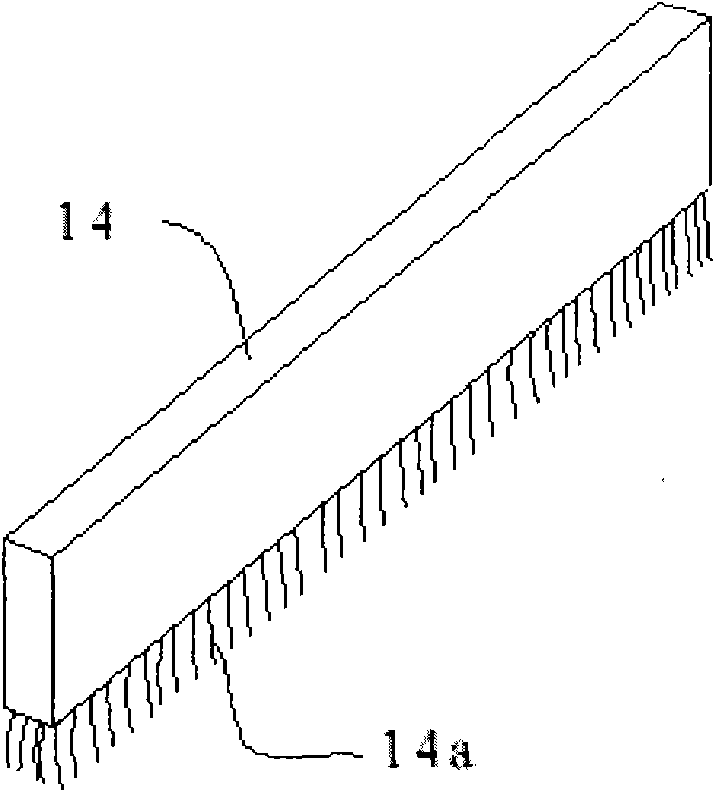

[0049] Place the 400-denier RYX90 ultra-high molecular weight polyethylene fiber produced by Ningbo Rongyi Chemical Fiber Technology Co., Ltd. on the creel 11. The spindles on the creel pass through the cluster frame 12 and then gather into bundles. After passing through the static electricity generation device 13, they enter the static elimination Device 14, eliminates static electricity.

[0050] 2. Preheat

[0051] The uniformly spread fibers were preheated at a temperature of 50 °C through a heat shaft.

[0052] 3. Curly.

[0053] 4. Dry

[0054] The crimped ultra-high molecular weight polyethylene long fibers are sequentially subjected to the first stage drying, the second stage drying, and the third stage drying:

[0055] 4a. Introduce the pre-dried ultra-high molecular weight polyethylene long fibers 4 into the first drying chamber 1 for first-stage drying, control the direction of the hot air to blow from the bottom to the top o...

Embodiment 2

[0061] 1. The fibers spread evenly

[0062] In the present embodiment, the fiber uniform spreading process is the same as in embodiment 1.

[0063] 2. Preheat

[0064] The uniformly spread fibers were preheated at a temperature of 42°C through a heat shaft.

[0065] 3. Curly.

[0066] 4. Dry

[0067] The crimped ultra-high molecular weight polyethylene long fibers are sequentially subjected to the first stage drying, the second stage drying, and the third stage drying:

[0068] 4a. Introduce the crimped ultra-high molecular weight polyethylene long fibers 4 into the first drying chamber 1 for first-stage drying, control the direction of hot air to blow from the bottom of the ultra-high molecular weight polyethylene long fibers 4 to the top, and set the drying temperature to 100°C. Set to 85m / min;

[0069] 4b. Introduce the ultra-high molecular weight polyethylene long fibers 4 after the first stage drying into the second drying chamber to carry out the second stage drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com