Regeneration control method for engineering plant

A construction machinery and regenerative control technology, applied in the direction of engine control, mechanical equipment, engine components, etc., can solve the problems of affecting normal work, cost increase, low operating efficiency, etc., and achieve the effect of improving operating efficiency and increasing absorbed power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

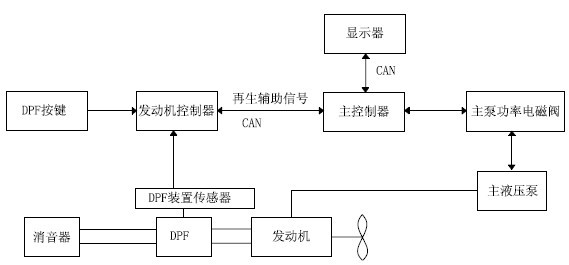

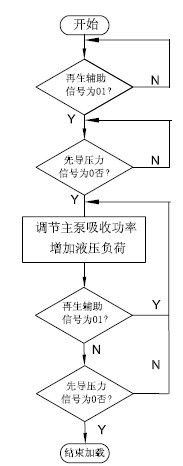

[0017] Embodiment one: see Figures 1 to 5 As shown, a construction machinery regeneration control method, when the construction machinery is in a high-load operation state, the exhaust temperature of the engine is higher than the automatic regeneration temperature, the engine controller automatically controls the DPF to achieve automatic regeneration; when the construction machinery is in a low-load operation or idle speed When idling, at this time the engine exhaust temperature is lower than the automatic regeneration temperature, the engine controller sends a signal to the main controller to increase the power solenoid valve current of the main hydraulic pump, increase the absorbed power of the main hydraulic pump, increase the engine exhaust temperature, and realize regeneration .

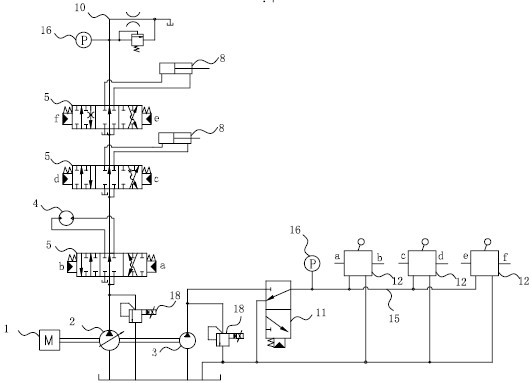

[0018] figure 2 It is the hydraulic circuit device diagram of the engineering model in this embodiment. The hydraulic circuit device of the hydraulic excavator includes: a variable capacity t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com