Composite diaphragm, preparation method and battery thereof

A technology of composite diaphragm and heat insulation layer, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as poor safety performance of the diaphragm, and achieve the effect of enhancing high temperature safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

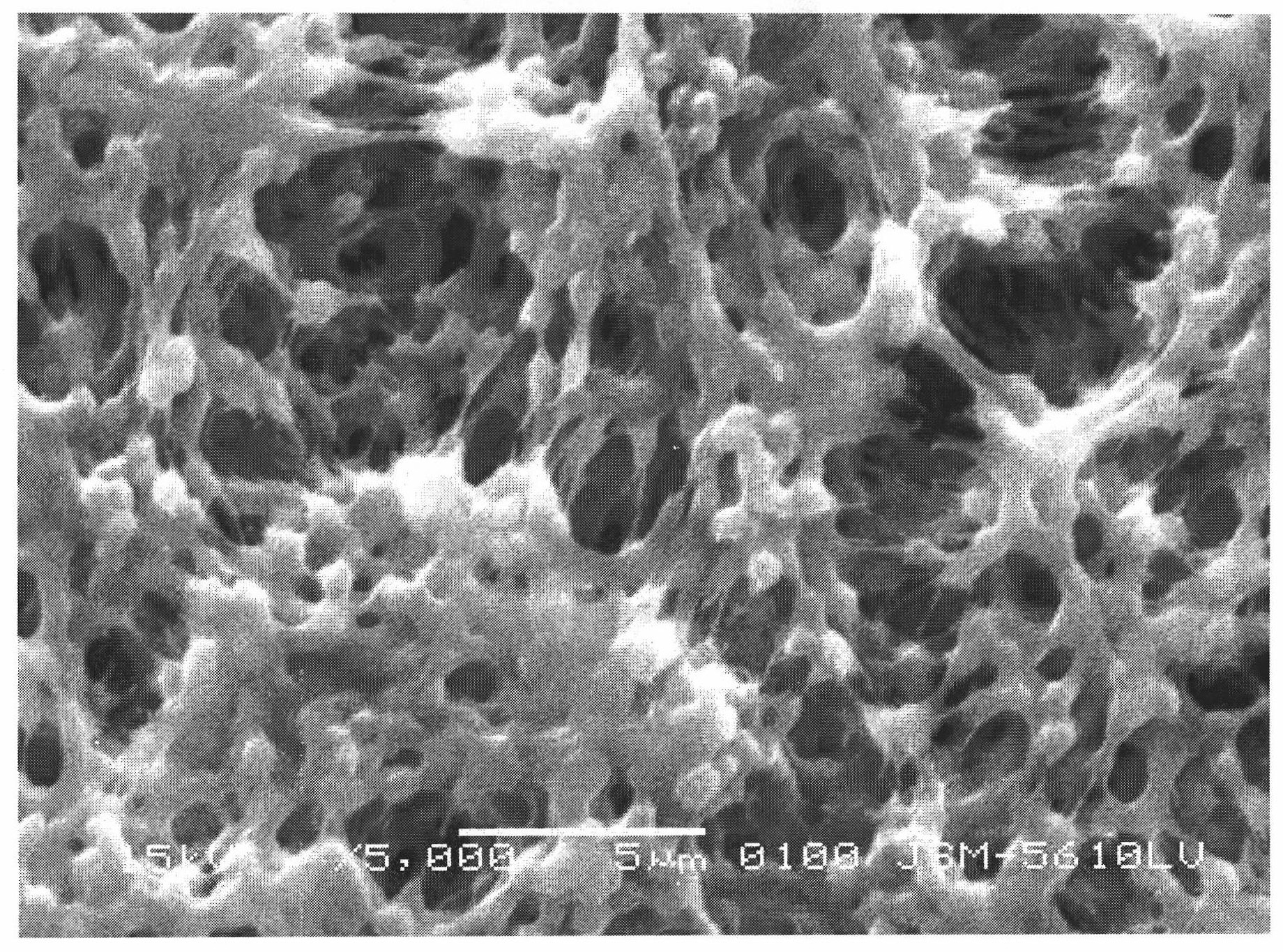

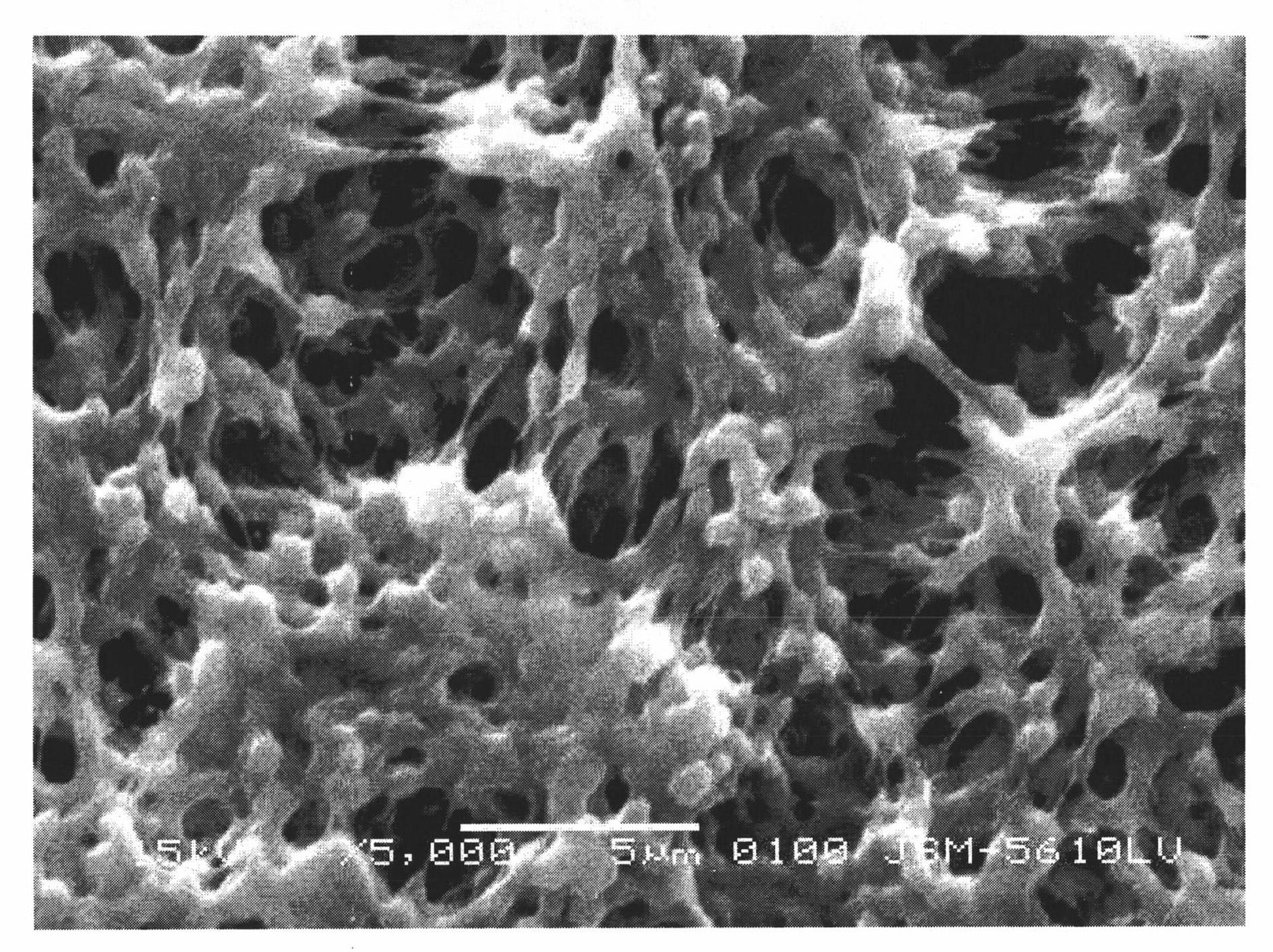

Image

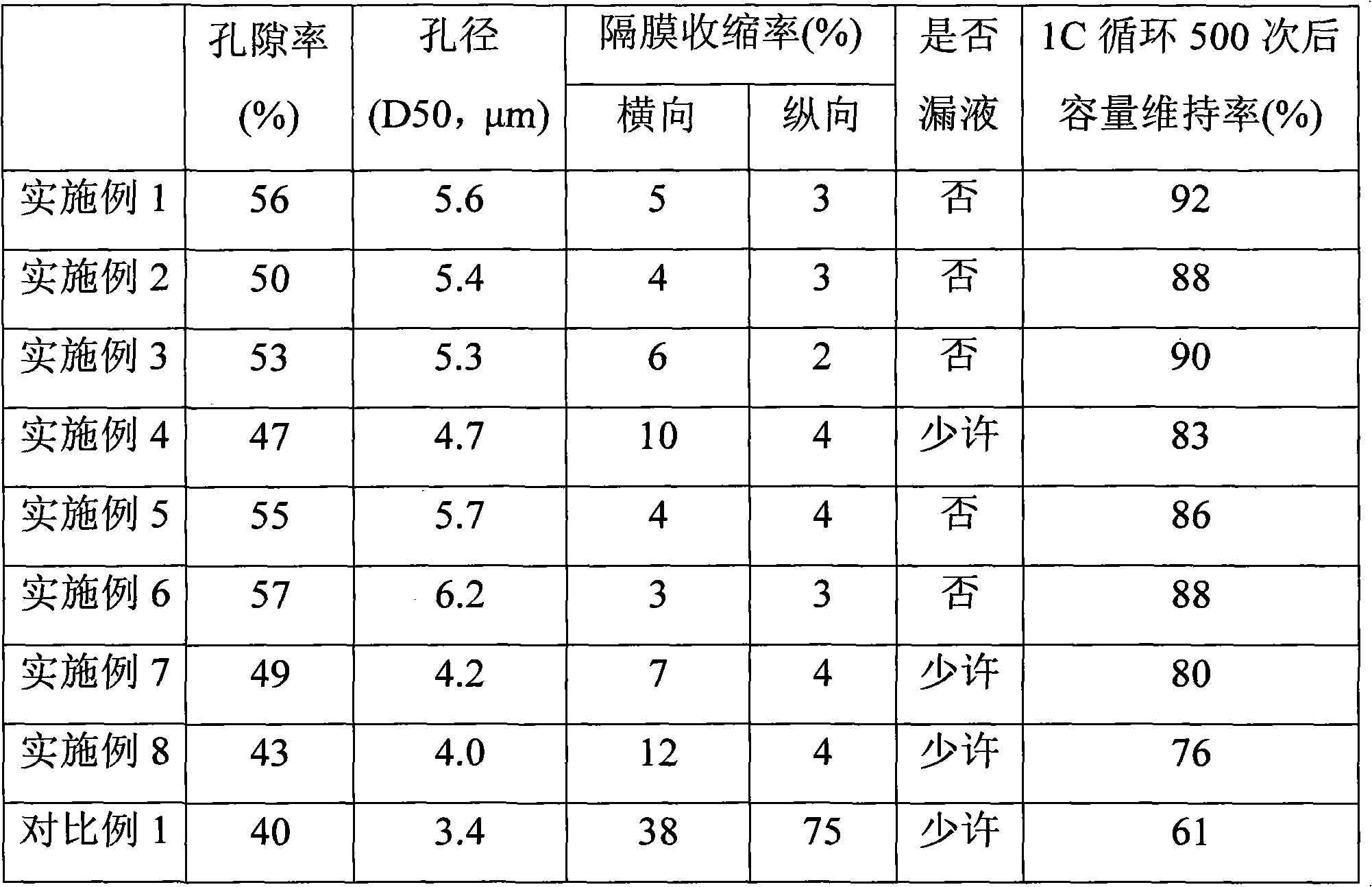

Examples

preparation example Construction

[0028] A kind of preparation method of above-mentioned composite diaphragm, it comprises the steps:

[0029] (1) Dispersing the nano-inorganic oxide in a dispersant to make a slurry, and then coating the slurry on both upper and lower surfaces of the base layer to form a thermal insulation layer;

[0030] (2) dissolving the polymer in a solvent, adding a plasticizer and stirring evenly to make a polymer coating solution; coating the polymer coating solution on the heat-insulating layer described in step (1);

[0031] (3) The product of step (2) is vacuum-dried at 50-90°C.

[0032] Wherein, the dispersant in step (1) is well known to those skilled in the art, as long as it has a low boiling point and is volatile, such as acetone, toluene and the like.

[0033] The dosage of the dispersant per gram of nano inorganic oxide is preferably 100-200 grams.

[0034] The preferred operation of step (1) is: adding the nano-inorganic oxide into the dispersant and stirring, controlling t...

Embodiment 1

[0048] ① Take polypropylene microporous membrane as the base layer, with a thickness of 16 μm and a porosity of 38%.

[0049] 10gAl 2 o 3 (average particle size 50nm) was added into 1500g of dispersant acetone and stirred, the rotation speed was controlled at 1200r / min, and stirred for 1h. Then disperse with ultrasonic wave, control the power of 100W, and continue ultrasonication for 30min; finally obtain the slurry. Spray the slurry evenly on the upper and lower sides of the base.

[0050] ② Take 30g of hexafluoroethylene-vinylidene fluoride copolymer (HFP-PVDF) (number average molecular weight is 5×10 5 ) into 2500g solvent acetone and stir until it is completely dissolved, control the speed at 1200r / min, stir for 2h, and the temperature of dissolution is 60°C; then add 40g of plasticizer dimethyl carbonate (DMC) to the above solution, and stir for 30min , the rotating speed is 1200r / min, forming a coating solution. Spray the coating solution on the outer surfaces of th...

Embodiment 2

[0054] ① Take polyethylene microporous membrane as the base layer, its thickness is 16μm, and the porosity is 38%.

[0055] 10gSiO 2 (average particle size 50nm) was added into 1500g of dispersant acetone and stirred, the rotation speed was controlled at 1200r / min, and stirred for 1h. Then disperse with ultrasonic wave, control the power of 100W, and continue ultrasonication for 30min; finally obtain the slurry. Spray the slurry evenly on the upper and lower sides of the base.

[0056] ② 30g polymer hexafluoroethylene-vinylidene fluoride copolymer (HFP-PVDF) (number average molecular weight is 5×10 5 ) into 2500g of acetone and stir until completely dissolved, control the speed at 1200r / min, stir for 2h, and the temperature of dissolution is 60°C; then add 40g of dimethyl carbonate (DMC) to the above solution, stir for 30min, and the speed is 1200r / min to form a coating liquid. Spray the coating solution on the outer surfaces of the two layers of insulation.

[0057] ③ T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com