Method for synthetizing polycarbosilane under atmospheric pressure

A technique for synthesizing polycarbosilane under normal pressure, which is applied in the field of synthesizing polycarbosilane under normal pressure, can solve the problems of not reaching the synthesis yield of high-pressure method, achieve the effects of easy batch synthesis, simple equipment, and lower reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

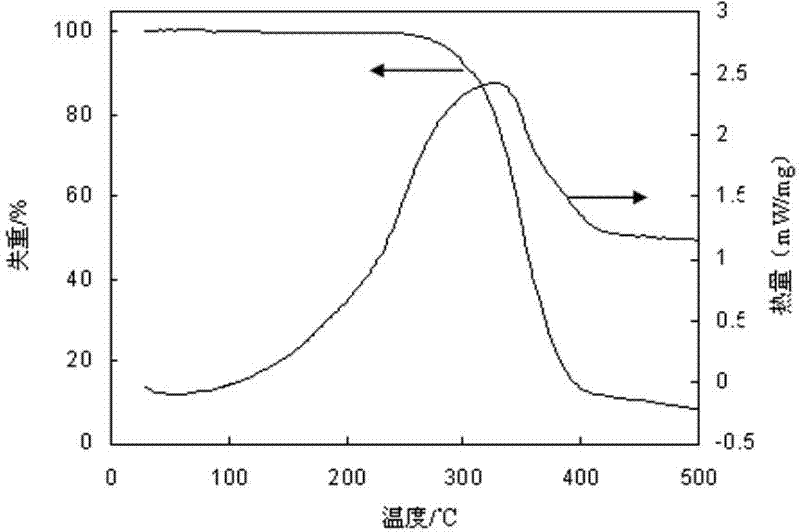

[0018] (1) Under the protection of high-purity nitrogen, the solid raw material PDMS is cracked and converted into LPS in a nitrogen atmosphere above 360 °C; (2) 200g LPS is placed in an atmospheric pressure high-temperature cracking synthesis reactor, and 65g of raw materials are added to LPS PDMS, stirred evenly, sealed, and replaced the gas in the kettle with high-purity nitrogen three times; under the protection of high-purity nitrogen, the temperature was raised to 280 ° C for 6 h; (3) the temperature was programmed to 410 ° C for 10 h, and 172 g of the product PCS was obtained after cooling.

[0019] The product PCS has a softening point of 180-195°C and a ceramic yield of 61.9wt%. It can be dissolved in organic solvents such as tetrahydrofuran and xylene, and the synthesis yield is 64.9%.

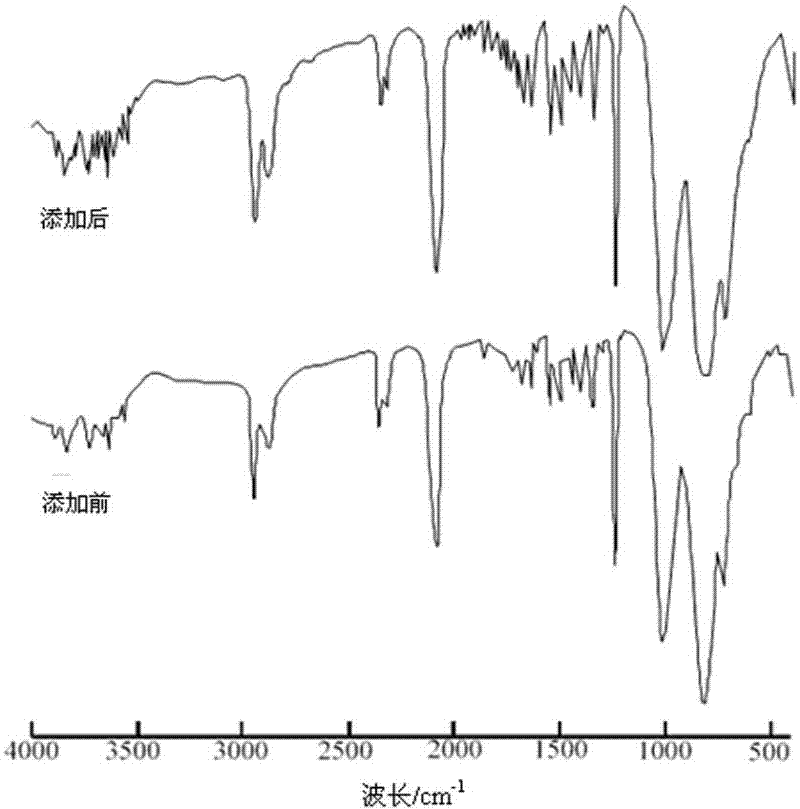

[0020] figure 2 is the FTIR spectrum of the product PCS. Depend on figure 2 It can be known that, compared with the existing atmospheric pressure catalytic synthesis method, th...

Embodiment 2

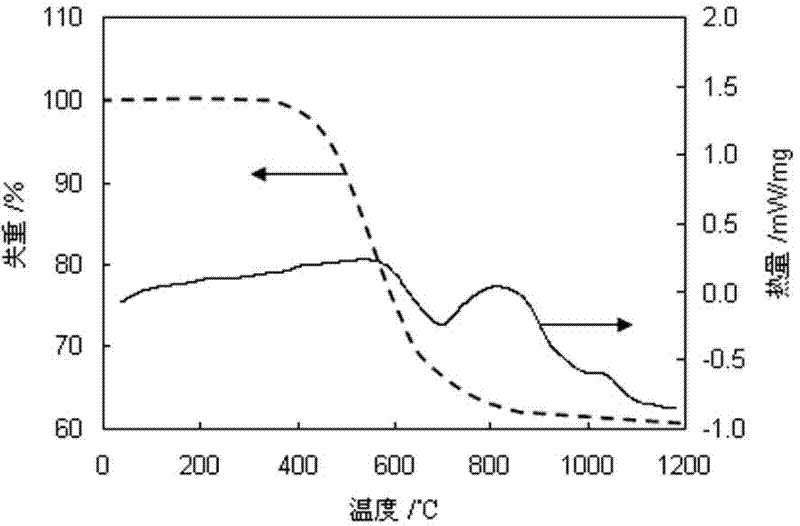

[0023] (1) Same as step (1) of Example 1; (2) Put 200g LPS in the normal pressure high temperature pyrolysis synthesis reaction kettle, add 200g raw material PDMS to the LPS, stir evenly, seal, replace the gas in the kettle with high-purity nitrogen Three times, under the protection of high-purity nitrogen, the temperature was raised to 300 ° C for 3 h; (3) then the temperature was programmed to 420 ° C for 6 h, and after cooling, 241 g of the product PCS was obtained.

[0024] The product PCS has a softening point of 185-200°C and a ceramic yield of 63.7wt%. It can be dissolved in organic solvents such as tetrahydrofuran and xylene, and the synthesis yield is 60.3%.

Embodiment 3

[0026] (1) Same as step (1) of Example 1; (2) Put 200g LPS in the normal pressure high temperature pyrolysis synthesis reaction kettle, add 100g raw material PDMS to the LPS, stir evenly, seal, replace the gas in the kettle with high-purity nitrogen Three times, under the protection of high-purity nitrogen, the temperature was raised to 330°C for 2 hours; (3) Then the temperature was programmed to rise to 370°C for 12 hours, and 184 g of the product PCS was obtained after cooling.

[0027] The product PCS has a softening point of 170-180°C and a ceramic yield of 59.1wt%. It can be dissolved in organic solvents such as tetrahydrofuran and xylene, and the synthesis yield is 61.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com