A kind of adsorbable heavy metal ion MOF material and preparation method thereof

A technology for adsorbing heavy metals and heavy metal ions, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as poor heavy metal ion adsorption performance, achieve good adsorption effect, easy to manufacture, and improve roughness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

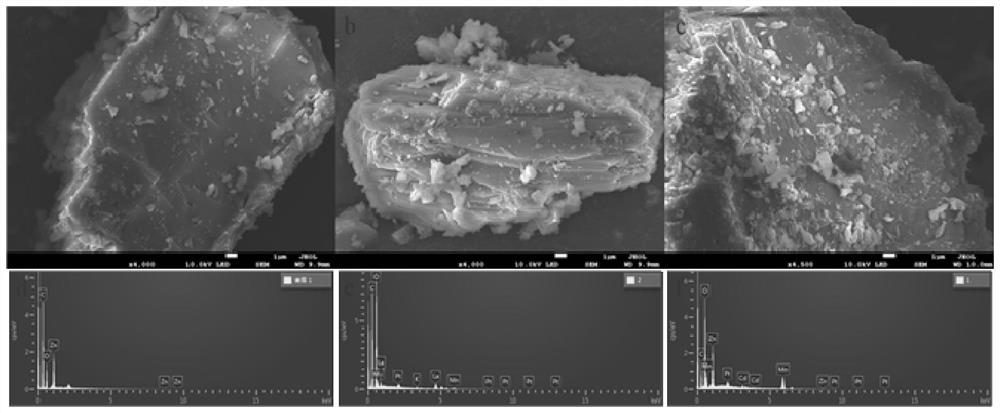

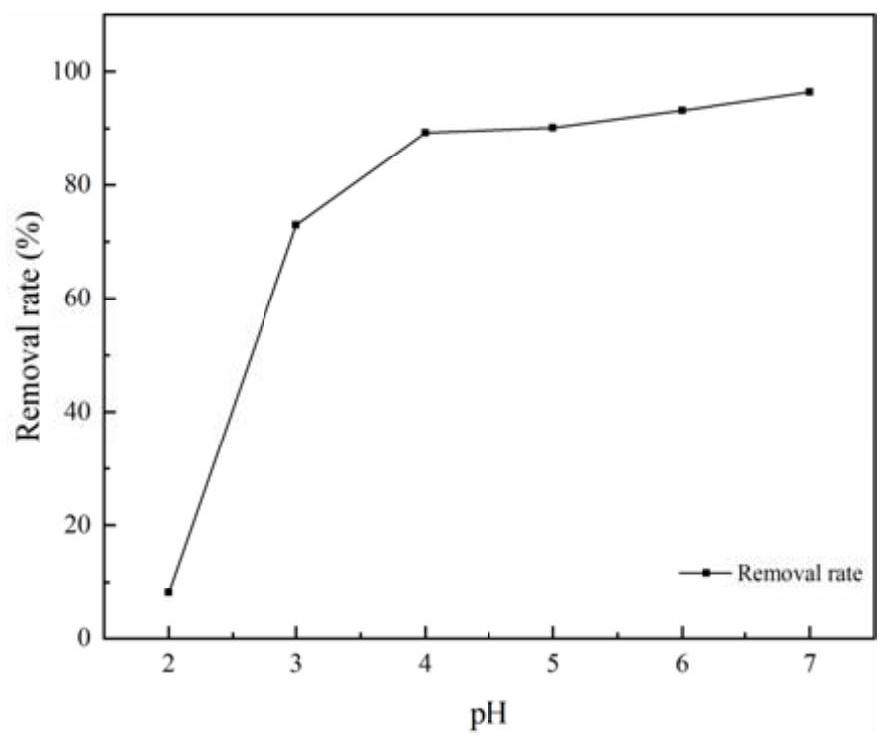

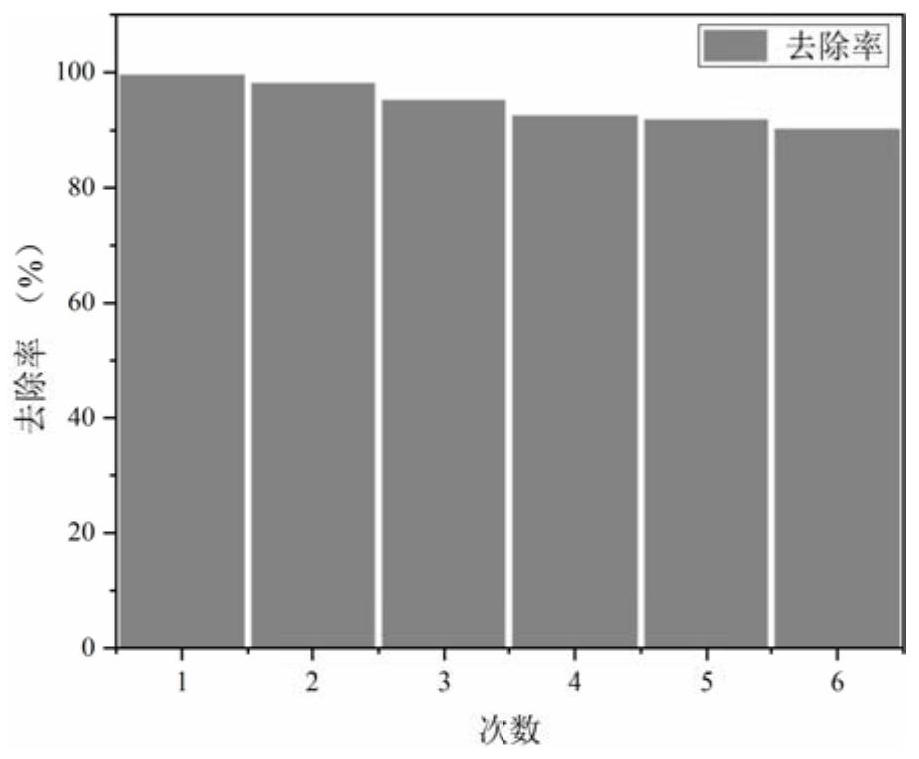

[0039] This embodiment provides a method for preparing MOF materials capable of adsorbing heavy metal ions,

[0040] Preparation of Zn-MOF:

[0041] 1,3-bis(4-pyridyl)propane, 2,5-dihydroxyterephthalic acid and Zn(NO 3 ) 2 ·6H 2 O was dissolved in a mixed solution of distilled water and DMF with a volume ratio of 2:1, the concentrations of which were 9 mg / mL, 6 mg / mL and 0.025 mol / L, and stirred evenly, then placed in a polytetrafluoroethylene autoclave, React at a constant temperature of 150°C for 24 hours, and drop to 25°C at a rate of 5°C / h to obtain the MOF material——brown block crystal Zn-MOF. The monomer structure diagram is shown in Figure 4 .

[0042] Preparation of K-Zn-MOF:

[0043] 1) Weigh the Zn-MOF material and potassium permanganate according to the mass ratio of 8:3, and then use the grinding method to mix and grind for 10 minutes;

[0044] 2) Pour it into a 100mL beaker after mixing and grinding evenly, then add 50mL of distilled water into it, raise th...

Embodiment 2

[0060] This embodiment provides a method for preparing MOF materials capable of adsorbing heavy metal ions,

[0061] Preparation of La-MOF:

[0062] 2,5-dihydroxyterephthalic acid, 1,3-bis(4-pyridyl)propane and La(NO 3 ) 3 ·6H 2 O was dissolved in distilled water with concentrations of 10mg / mL, 9.9mg / mL and 0.05mol / L respectively. After stirring evenly, it was placed in a polytetrafluoroethylene autoclave and placed in a closed oven at a constant temperature of 140°C. Under the same conditions, the reaction was carried out for 50 h, and the temperature was lowered to 25 °C at a rate of 5 °C / h to obtain a colorless bulk crystal La-MOF.

[0063] Preparation of K-La-MOF:

[0064] 1) Weigh the La-MOF material and potassium permanganate according to the mass ratio of 8:3, and then use the grinding method to mix and grind for 10 minutes;

[0065] 2) Pour it into a 100mL beaker after mixing and grinding evenly, then add 50mL of distilled water into it, raise the temperature to 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com