Method for synthesizing high-melting-point polycarbosilane at normal pressure

A polycarbosilane and atmospheric pressure synthesis technology is applied in the field of atmospheric pressure synthesis of high-melting polycarbosilane, which can solve the problems of difficulty in batch preparation, high solvent dehydration requirements, complicated steps, etc., and achieves easy batch synthesis, improved linearity, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] (1) Under the protection of high-purity nitrogen, the solid raw material polydimethylsilane (PDMS) is cracked and converted into liquid polysilane (LPS) in a nitrogen atmosphere at 360 °C;

[0025] (2) Put 200g of the LPS obtained in step (1) in a pyrolysis synthesis reaction kettle under normal pressure, add 10g of polymethylhydrogensilane to the LPS, and replace the gas in the kettle with high-purity nitrogen three times; raise the temperature under the protection of high-purity nitrogen React at 220°C for 6 hours, then program temperature increase (at a rate of 0.2°C / min) to 440°C for 8 hours to obtain a crude product;

[0026] (3) Dissolve and filter the crude product obtained in step (2) in xylene (mass ratio of crude product to xylene is 1:1), distill the filtrate at 350°C, and obtain 118.7g of light yellow resinous PCS precursor after cooling body.

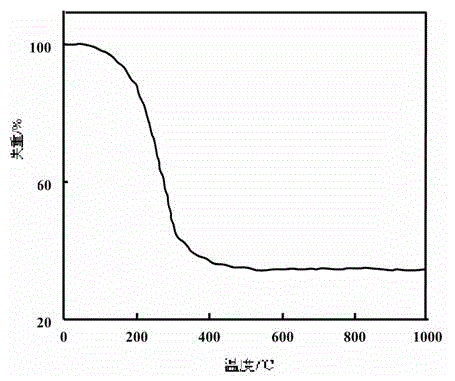

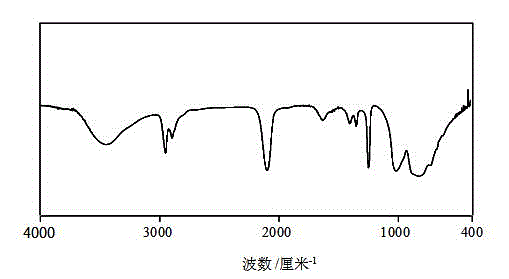

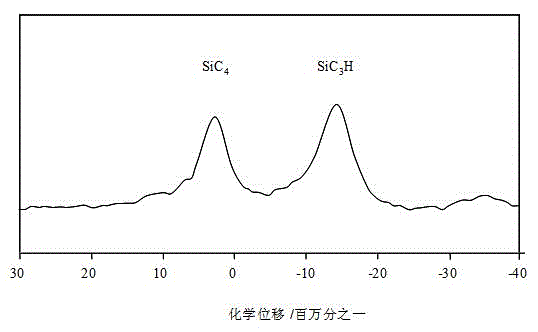

[0027] The product PCS obtained in this example has a mel...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] (1) with embodiment 1 step (1);

[0033] (2) Put 200g of LPS in the high-temperature pyrolysis synthesis reaction kettle under normal pressure, add 30g of polymethylhydrogensilane to the LPS, replace the gas in the kettle with high-purity nitrogen three times, and raise the temperature to 220°C for 6 hours under the protection of high-purity nitrogen. Then program temperature increase (at a rate of 0.2°C / min) to 430°C for 8 hours to obtain a crude product;

[0034] (3) The crude product was dissolved in xylene (mass ratio of crude product to xylene: 1:1), filtered, and the filtrate was distilled at 350°C. After cooling, 121.1 g of light yellow resinous PCS precursor was obtained.

[0035] The product PCS has a melting point of 255-279°C, a ceramic yield of 62.9wt%, and can be dissolved in organic solvents such as tetrahydrofuran and xylene.

Embodiment 3

[0037] This embodiment includes the following steps:

[0038] (1) with embodiment 1 step (1);

[0039] (2) Put 200g of LPS in the high-temperature pyrolysis synthesis reaction kettle under normal pressure, add 50g of polymethylhydrogensilane to the LPS, replace the gas in the kettle with high-purity nitrogen three times, and raise the temperature to 220°C for 4 hours under the protection of high-purity nitrogen. Then program temperature increase (at a rate of 0.2°C / min) to 420°C for 6 hours to obtain a crude product;

[0040] (3) The crude product was dissolved in xylene (the mass ratio of crude product to xylene was 1:1), filtered, and the filtrate was distilled at 350°C. After cooling, 123.7g of light yellow resinous PCS precursor was obtained.

[0041] The product PCS has a melting point of 259-281°C, a ceramic yield of 63.6wt%, and can be dissolved in organic solvents such as tetrahydrofuran and xylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com