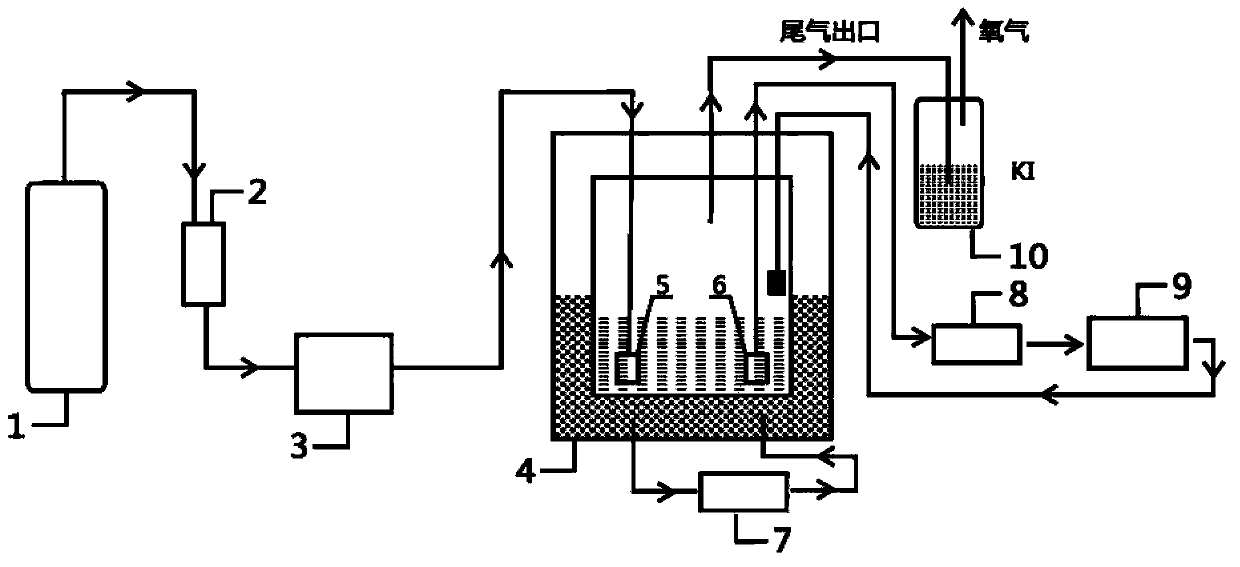

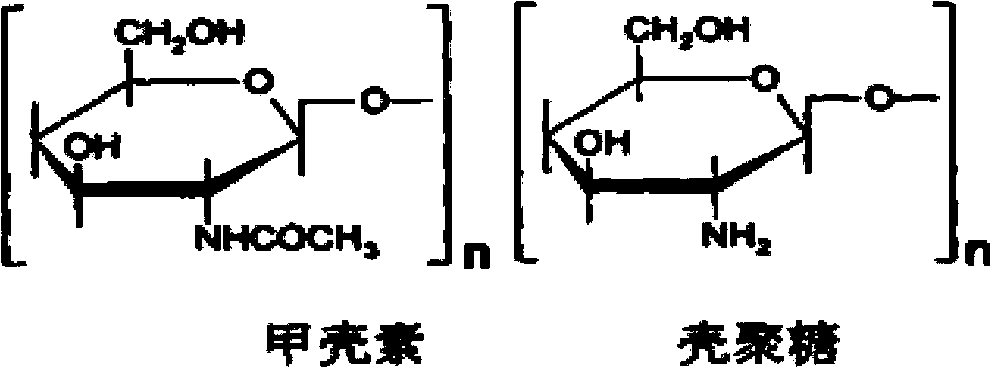

Device and method for preparing low molecular weight water-soluble chitosan through synergy of pulsed electric field and ozone

A technology of water-soluble chitosan and pulsed electric field is applied in the field of preparation of controllable low-molecular-weight chitosan, which can solve the problems of complex fermentation process, high equipment requirements, complicated post-processing, etc., and achieves increased degradation efficiency and product purity. High effect with short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The molecular weight of high molecular weight chitosan is 3.0×10 5 Da, the degree of deacetylation is greater than 85%, mixed with the aqueous solution containing acetic acid and placed in jacketed bottle 4, wherein the volume of chitosan acidic solution is 100mL, the mass concentration of chitosan is 100g / L, the mass fraction of acetic acid solution 3%. Open the valve of oxygen cylinder 1, open ozone generator 3, the ozone concentration that ozone generator produces is controlled as 10mg / L, and ozone is passed into chitosan acidic solution by gas distributor 5 with the speed of 0.1L / min, simultaneously, Turn on the constant temperature circulator 7 to keep the chitosan acidic solution at 25°C. Use peristaltic 8 pumps (HL-4 type constant flow pump) to continuously pump the chitosan-ozone mixed solution through the air filter 6 into the pulse electric field device 9 at a flow rate of 50mL / min for circulation treatment, and adjust the electric field strength to be 20kV / cm ...

Embodiment 2

[0039] The molecular weight of high molecular weight chitosan is 5.0×10 5 Da, the degree of deacetylation is greater than 95%, and the aqueous solution containing formic acid and hydrochloric acid is mixed evenly and placed in the jacket, wherein the volume of chitosan acidic solution is 200mL, the mass concentration of chitosan is 20g / L, and the mass fraction of formic acid solution is 0.5%, and the mass fraction of hydrochloric acid is 5.0%. Open the valve of the oxygen cylinder, turn on the ozone generator, pass the 1000mg / L of ozone produced by the ozone generator into the chitosan acidic solution from the gas distributor at a speed of 1.0L / min, and at the same time, open the constant temperature circulator to make the chitosan The acidic solution was kept at 30°C. Use a continuous constant flow pump to pump the chitosan-ozone mixed solution through the air filter into the pulse electric field device at a flow rate of 10mL / min for circulation treatment, adjust the electri...

Embodiment 3

[0041] The molecular weight of high molecular weight chitosan is 6.0×10 5 Da, the degree of deacetylation is greater than 90%, and the aqueous solution containing citric acid is mixed evenly and placed in the jacket, wherein the volume of chitosan acidic solution is 400mL, the mass concentration of chitosan is 1.0g / L, the mass of citric acid solution The score is 10%. Open the valve of the oxygen cylinder, turn on the ozone generator, pass the ozone 3500mg / L produced by the ozone generator into the chitosan acid solution from the gas distributor at a speed of 3.0L / min, and at the same time, open the constant temperature circulator to make the chitosan The acidic solution was kept at 35°C. Use a continuous constant flow pump to pump the chitosan-ozone mixed solution through the air filter into the pulse electric field device at a flow rate of 120mL / min for circulation treatment, adjust the electric field strength to 5kV / cm, pulse width 110μs, pulse frequency 1500Hz, pulse wave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com