Tunable Bragg stack

A device, alternating layer technology, used in lasers, nanotechnology, instruments, etc., can solve problems such as refractive index changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

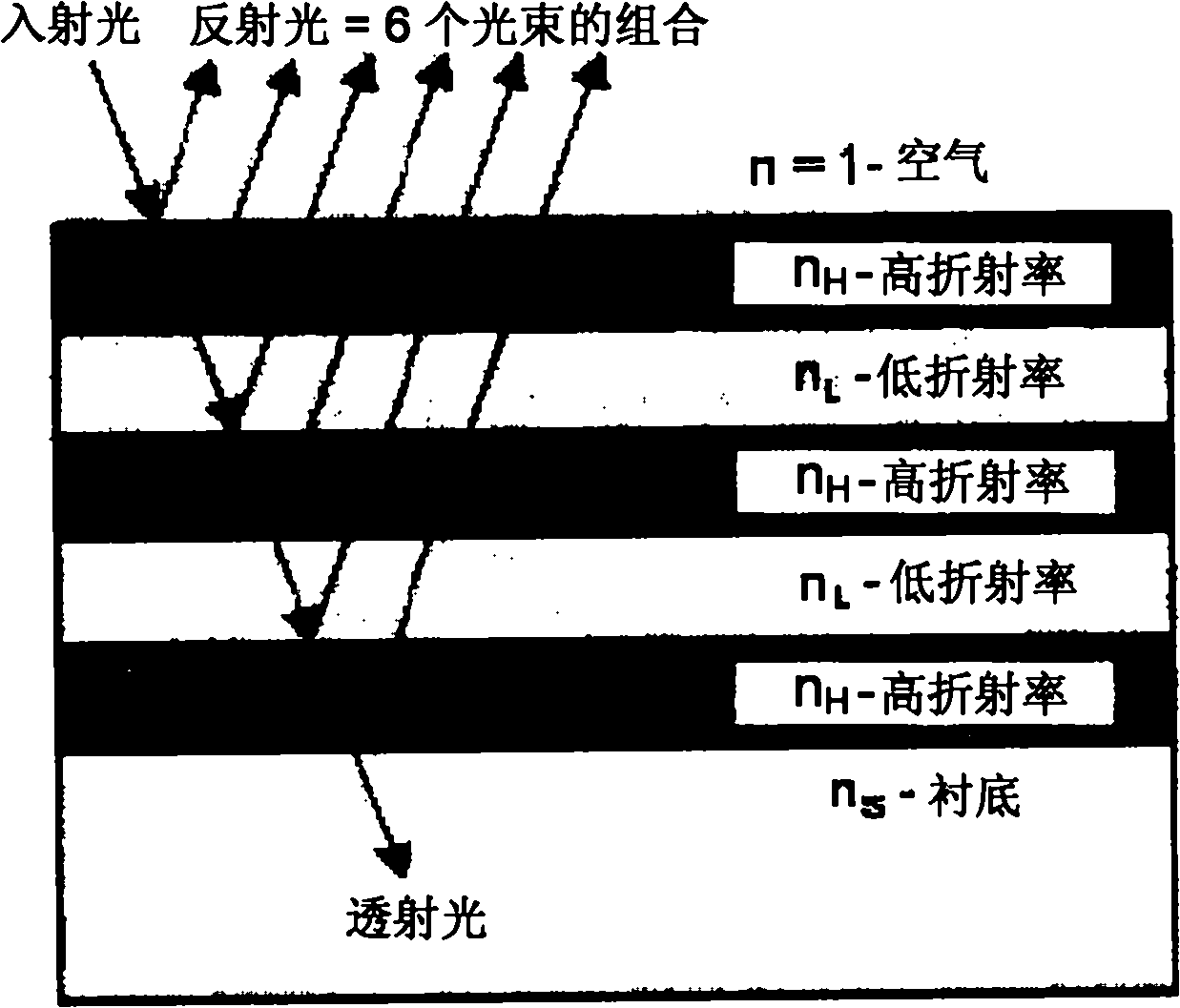

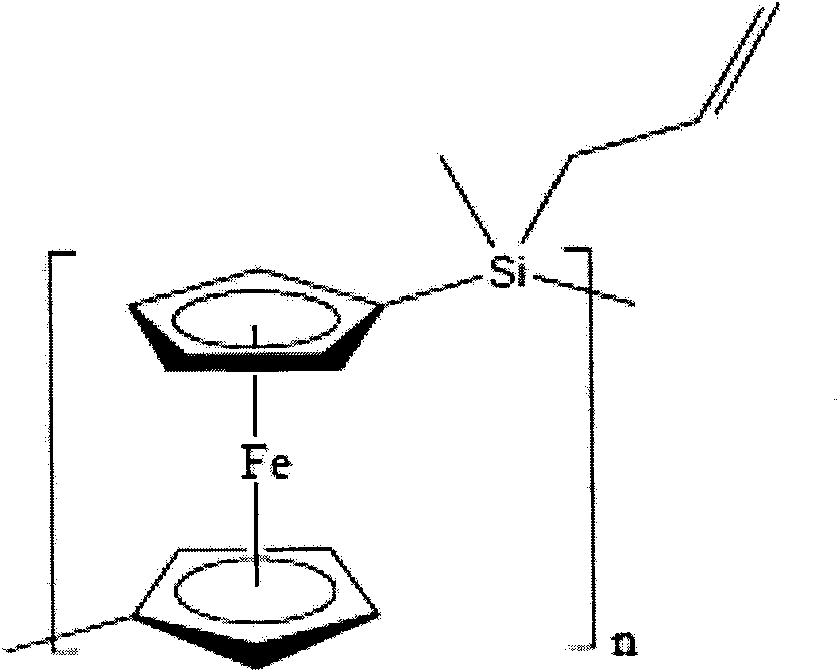

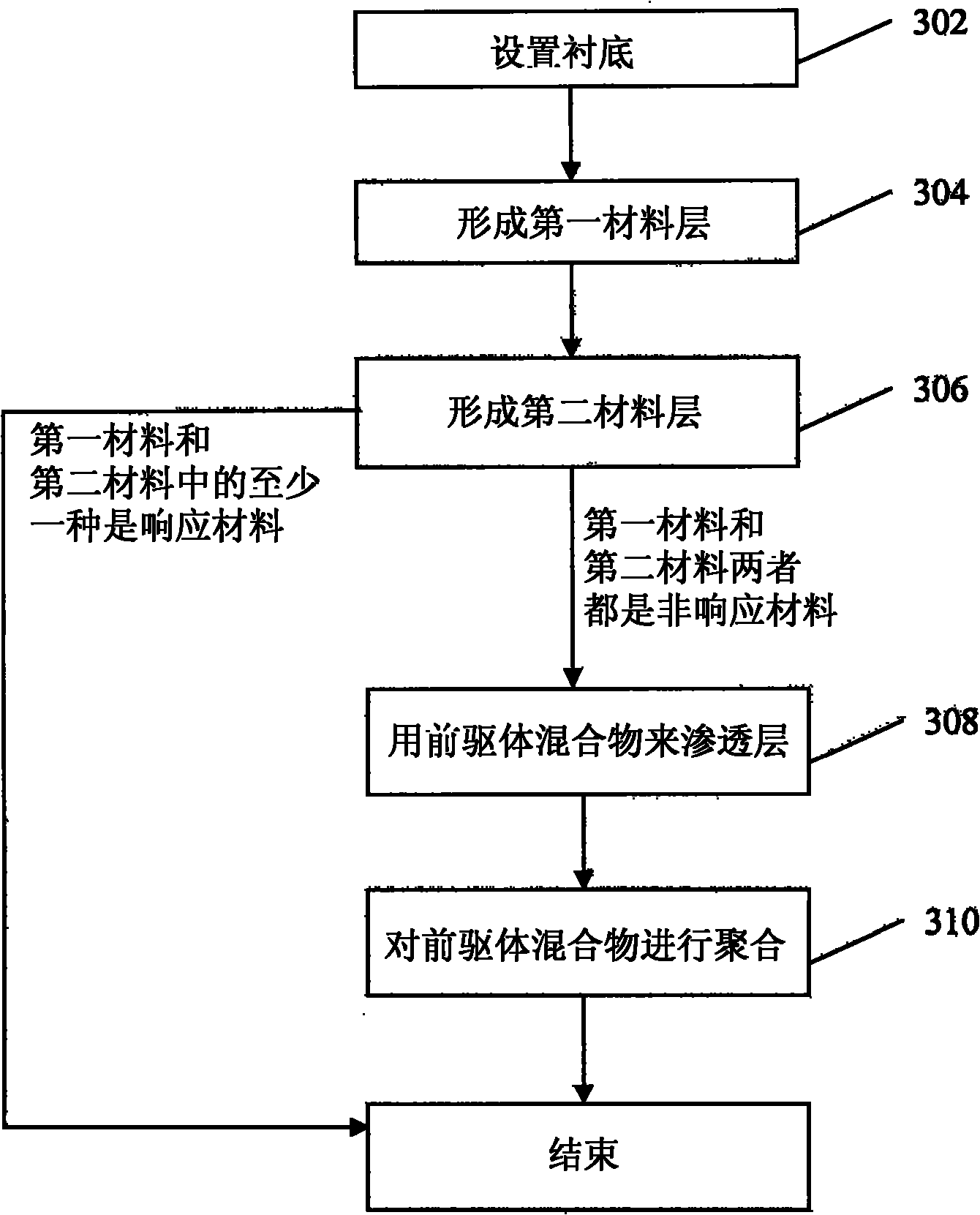

[0103] One example of an electrically tunable DBR is a composite polyferrocenesilane / nanoparticle DBR. The DBR comprises alternating layers of different nanoparticle layers, which are infiltrated with polyferrocenesilane (PFS). This structure can be used in electrochemical cells by first fabricating a composite DBR on a conductive electrode (e.g., fluorine-doped tin oxide, which can be transparent), and then integrating the DBR and its electrodes into an electrolytic electrochemical cell. Battery.

[0104] SiO 2 and TiO 2are two materials that can be used to build DBR structures. These two materials have different dielectric constants and can also be grown as highly uniform thin films using a wide range of techniques such as pulsed laser deposition, reactive sputtering or different types of chemical vapor deposition techniques (Jethmalani et al., Langmuir, 1997, Vol. 13, p. 2633). Furthermore, a combination of dip coating (Chen et al., Appl. Phys. Lett, 1999, Vol. 75, p. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com