Automotive rear axle driven bevel gear blank forging production line

A technology for automobile rear axle and gear blanks, which is used in manufacturing tools, other manufacturing equipment/tools, metal processing, etc. to achieve the effect of long die life, accurate height control, and avoidance of folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

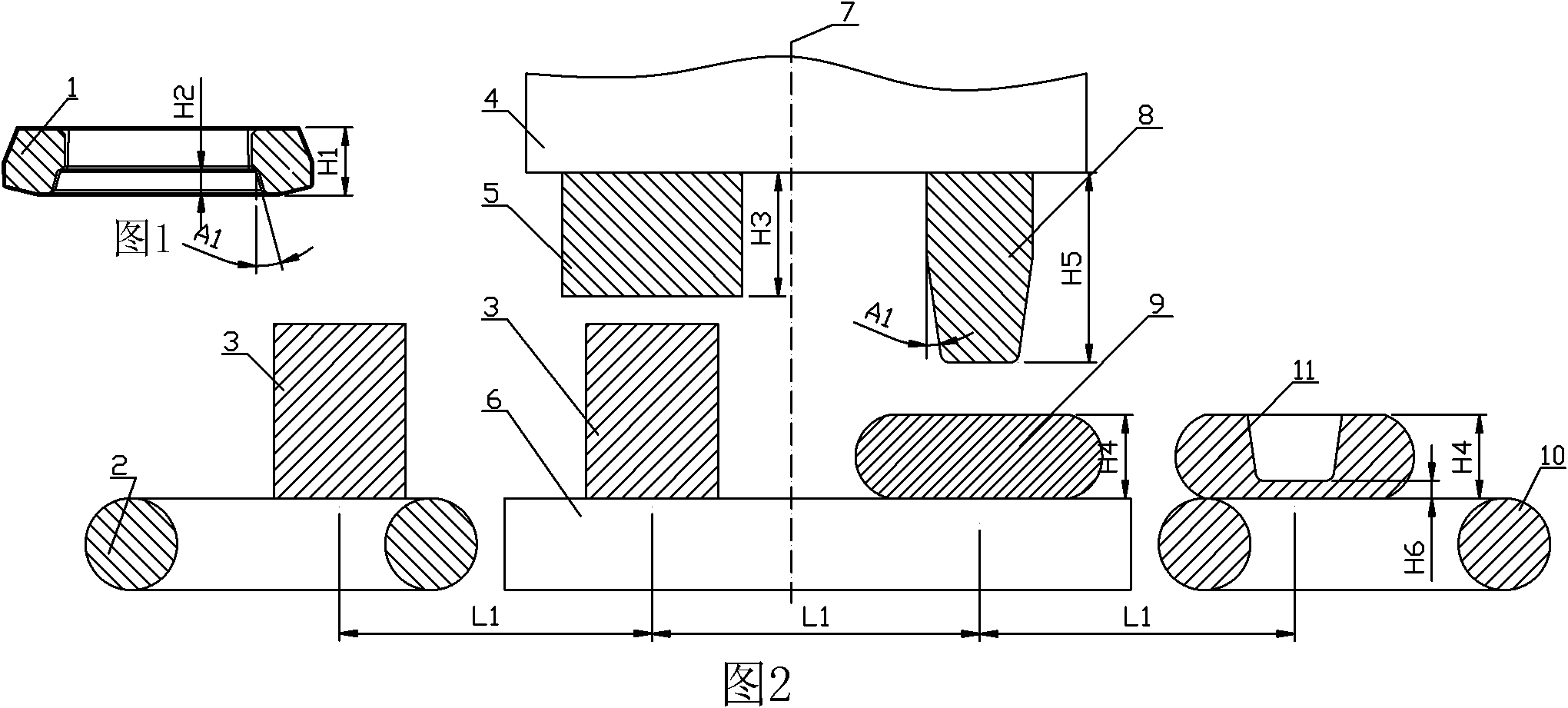

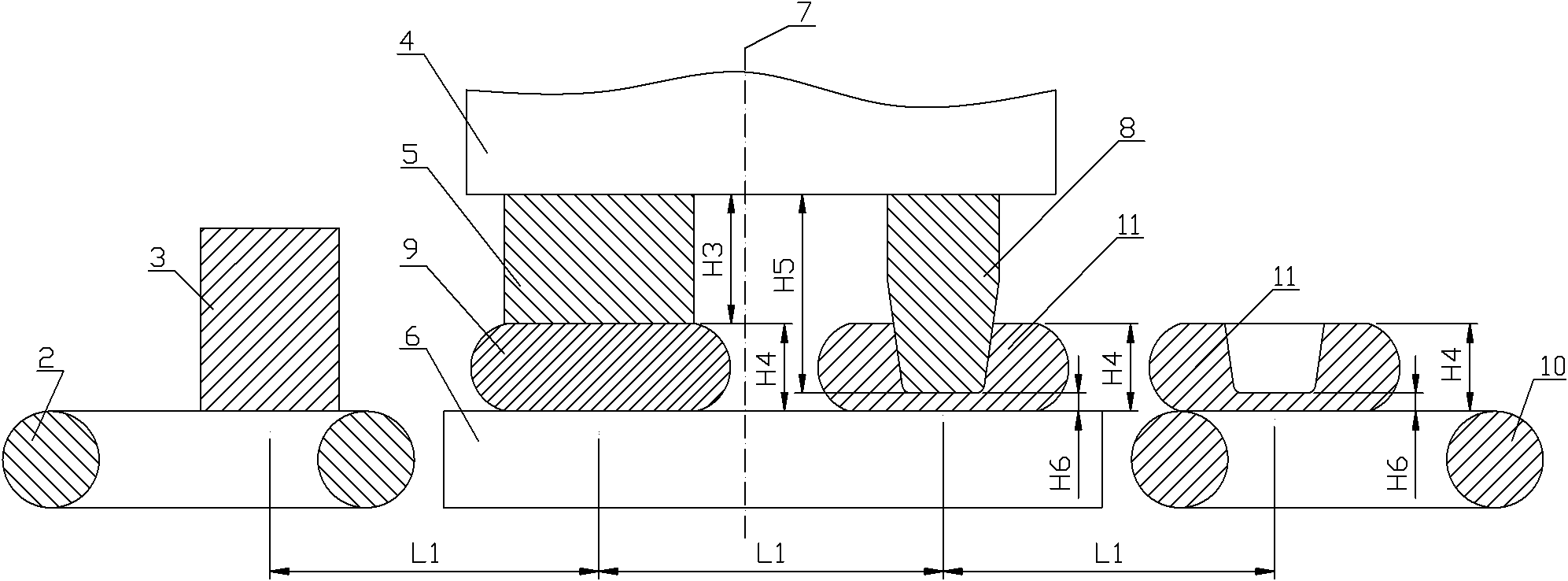

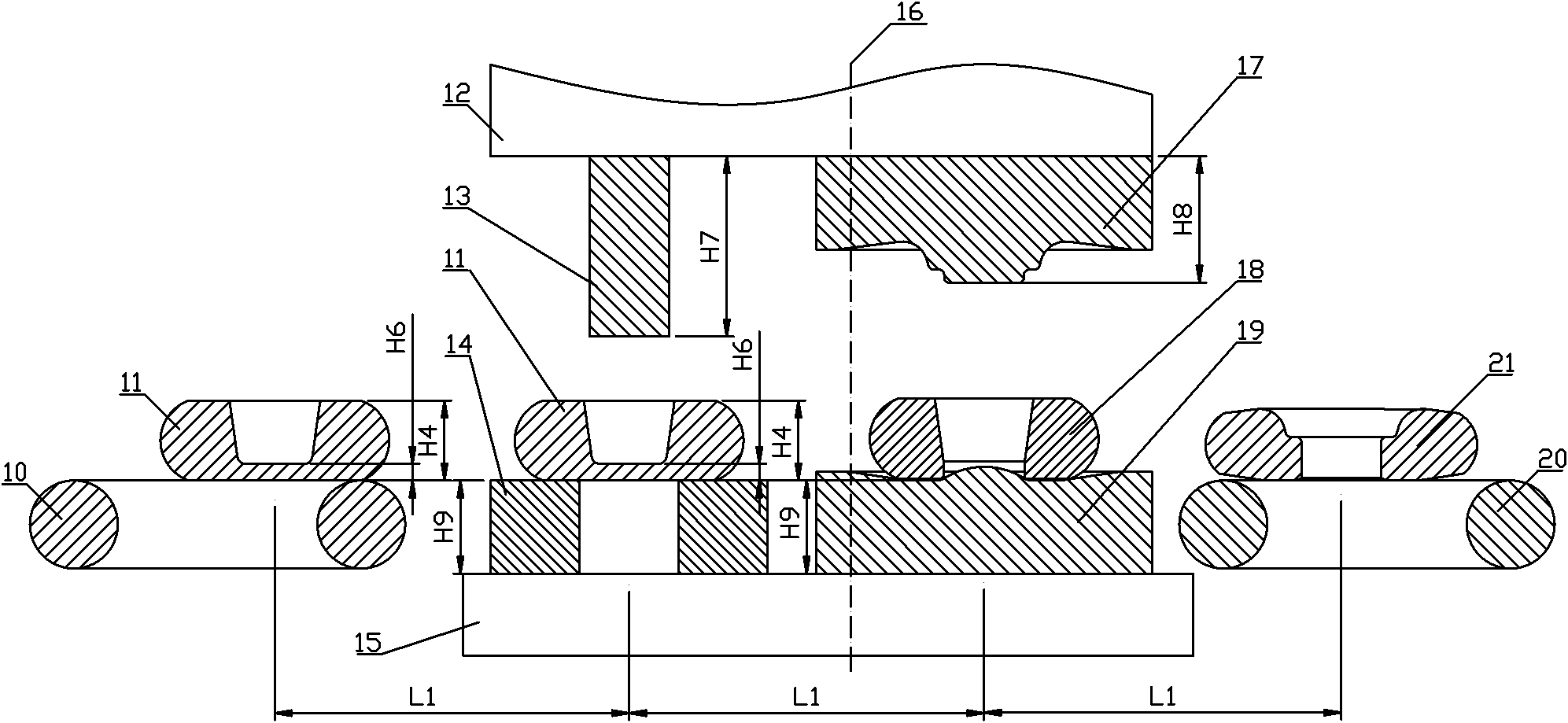

[0045] The invention provides a forging production line for driven spiral bevel gear blanks of automobile rear axles. The production line uses ordinary crank presses to press blanks, vertical hole reamers to ream holes, twin-roll rolling machines to shape and automatic upper and lower feeding mechanisms to transfer blanks. The technical problems to be solved are: (1) Install two stations on each of the two crank presses to complete pre-forging blanks such as upsetting, punching, punching and skinning, and pre-shaping; (2) Automatic up and down feeding mechanism It can timely and accurately load, unload, and transfer blanks for the crank press and the double-roller rolling machine, and must be fully automatic; (3) The double-roller rolling machine is used to complete the shaping process of the forging.

[0046] In order to better understand the present invention, the present invention will be further described in conjunction with the accompanying drawings by taking "the production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com