Method for removing fluorions from mineral water by using food grade alkaline magnesium carbonate

A mineral water and food-grade technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as poor taste, affecting the quality of mineral water, element loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

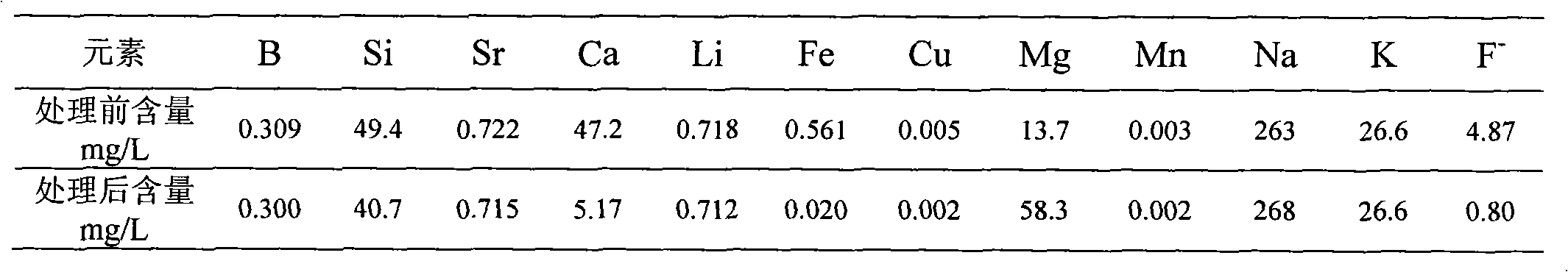

[0009] Take 1 liter of mineral water to be treated, keep the water temperature at 20°C, add 16 grams of food-grade basic magnesium carbonate powder under constant stirring, continue stirring for 2 hours, let stand for 8 hours, filter to remove insolubles in the water, and obtain pH=7.5 , and the fluoride ion (F - ) concentration is less than 1.5mg / L mineral water, the main element content in the mineral water before and after treatment is shown in Table 1.

[0010] Table 1

[0011]

Embodiment 2

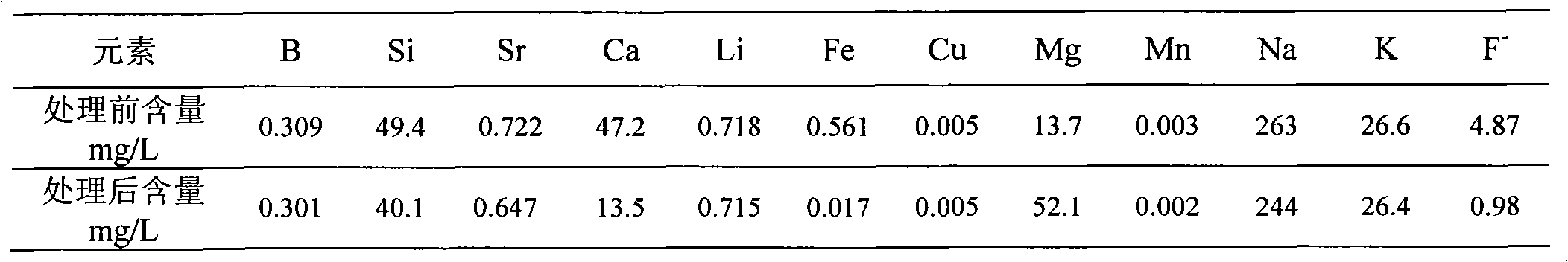

[0013] Take 1 liter of mineral water to be treated, keep the water temperature at 30°C, add 8 grams of food-grade basic magnesium carbonate powder under constant stirring, continue stirring for 6 hours, let stand for 16 hours, filter to remove insolubles in the water, and obtain pH = 7.5 , and the fluoride ion (F - ) concentration is less than 1.5mg / L mineral water, the content of main elements in the mineral water before and after treatment is shown in Table 2.

[0014] Table 2

[0015]

Embodiment 3

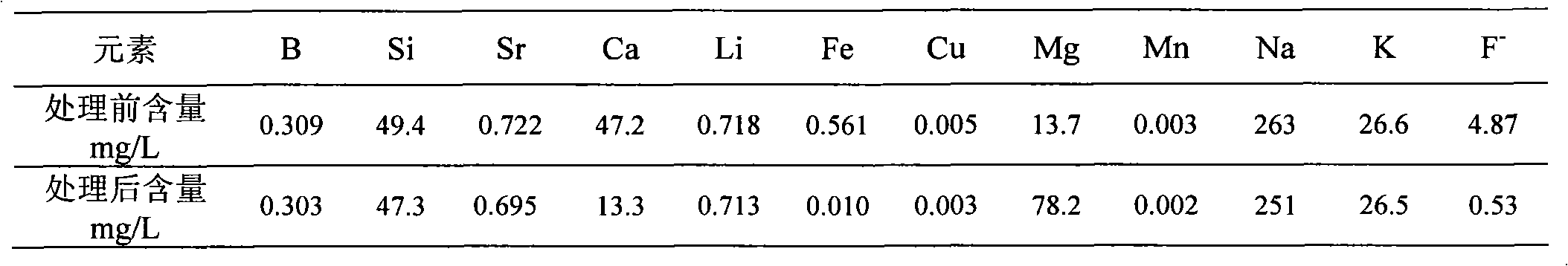

[0017] Take 1 liter of mineral water to be treated, keep the water temperature at 50°C, add 12 grams of food-grade basic magnesium carbonate powder under constant stirring, continue stirring for 4 hours, let stand for 12 hours, filter to remove insolubles in the water, and obtain pH=7.5 , and the fluoride ion (F - ) concentration is less than 1.5mg / L mineral water, the content of main elements in the mineral water before and after treatment is shown in Table 3.

[0018] table 3

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com