Method for synthesizing acrolein

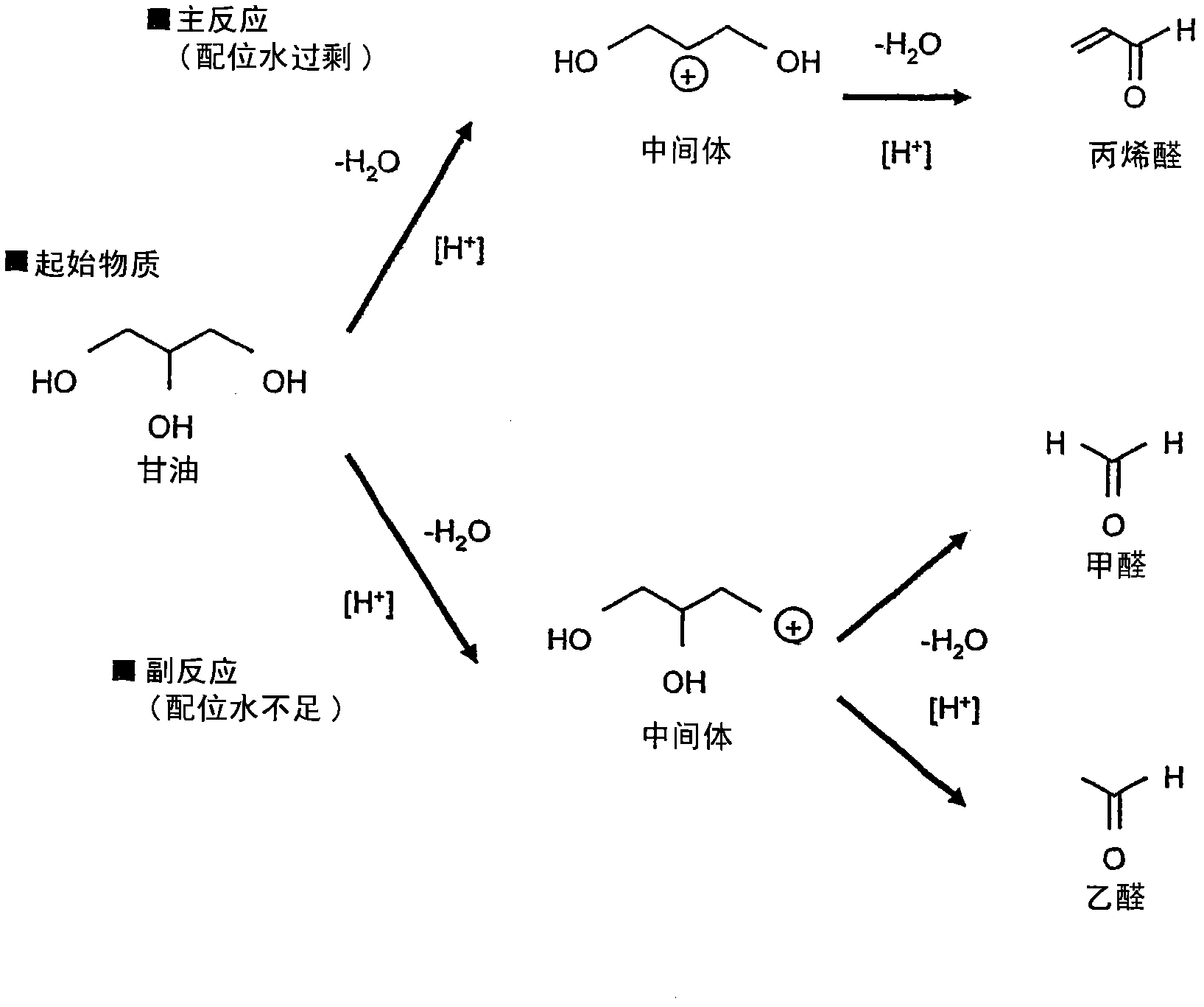

一种合成方法、丙烯醛的技术,应用在化学仪器和方法、混合机、流态混合器等方向,能够解决加长混合的时间、不易多层状的流动、得不到混合性等问题,达到改善混合性、混合性改善、压力降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

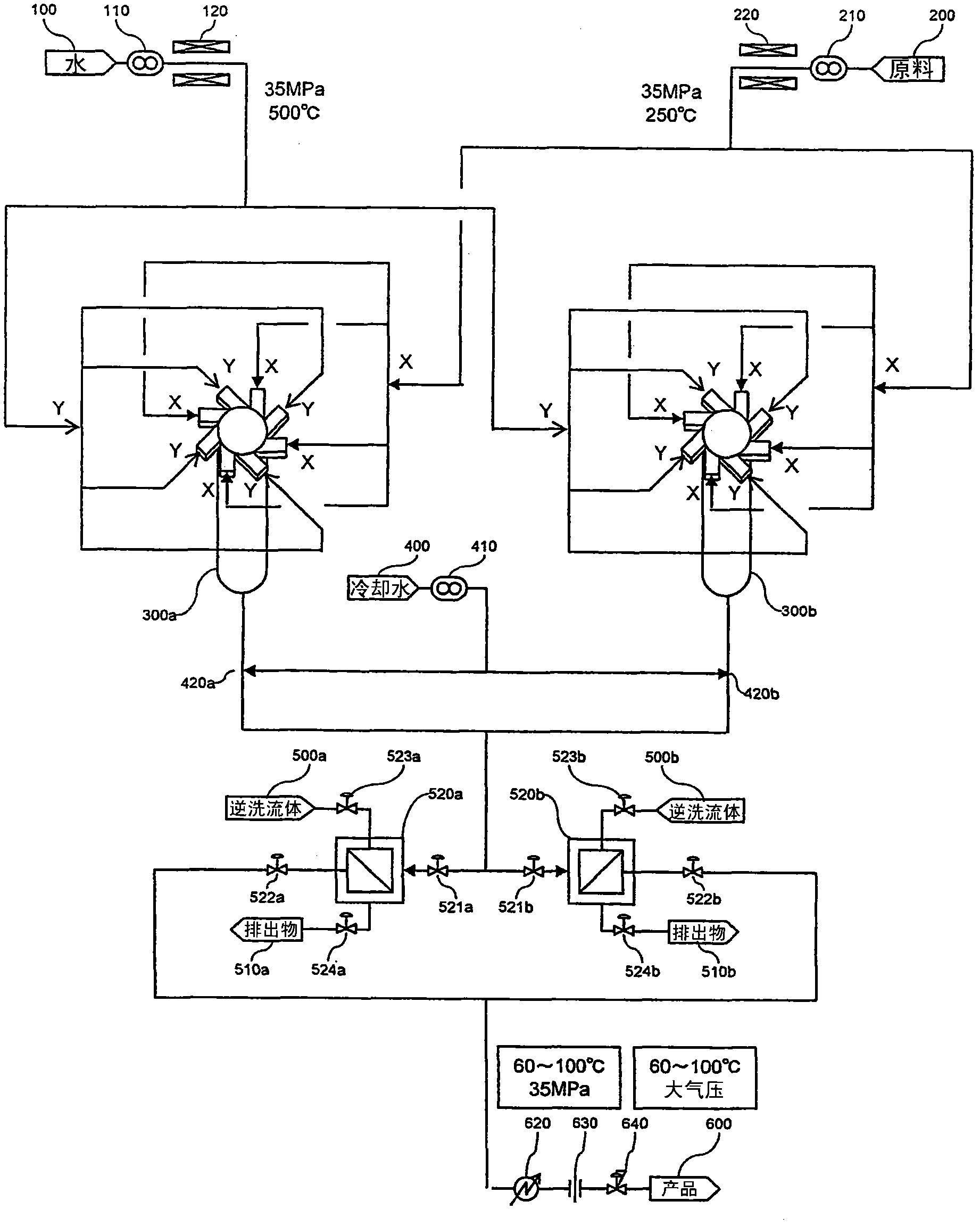

[0076] The process of selecting glycerin as a raw material, selecting supercritical water as water, mixing them to start a reaction, separating and removing by-products, and recovering a reaction liquid will be described below with reference to the accompanying drawings.

[0077] figure 2 It is a figure which shows one embodiment of the acrolein synthesis apparatus used in this invention. First, use the supercritical water high-pressure pump 110 to deliver water at 35 MPa, and use the supercritical water preheater 120 to raise the temperature to 500°C. In addition, the raw material composed of glycerin and dilute sulfuric acid is transported at 35 MPa by the raw material high-pressure pump 210, heated to 250°C by the raw material preheater 220, mixed by the reaction devices 300a and 300b using swirling flow, and instantly heated at 400°C and 35MPa. The acrolein synthesis reaction starts.

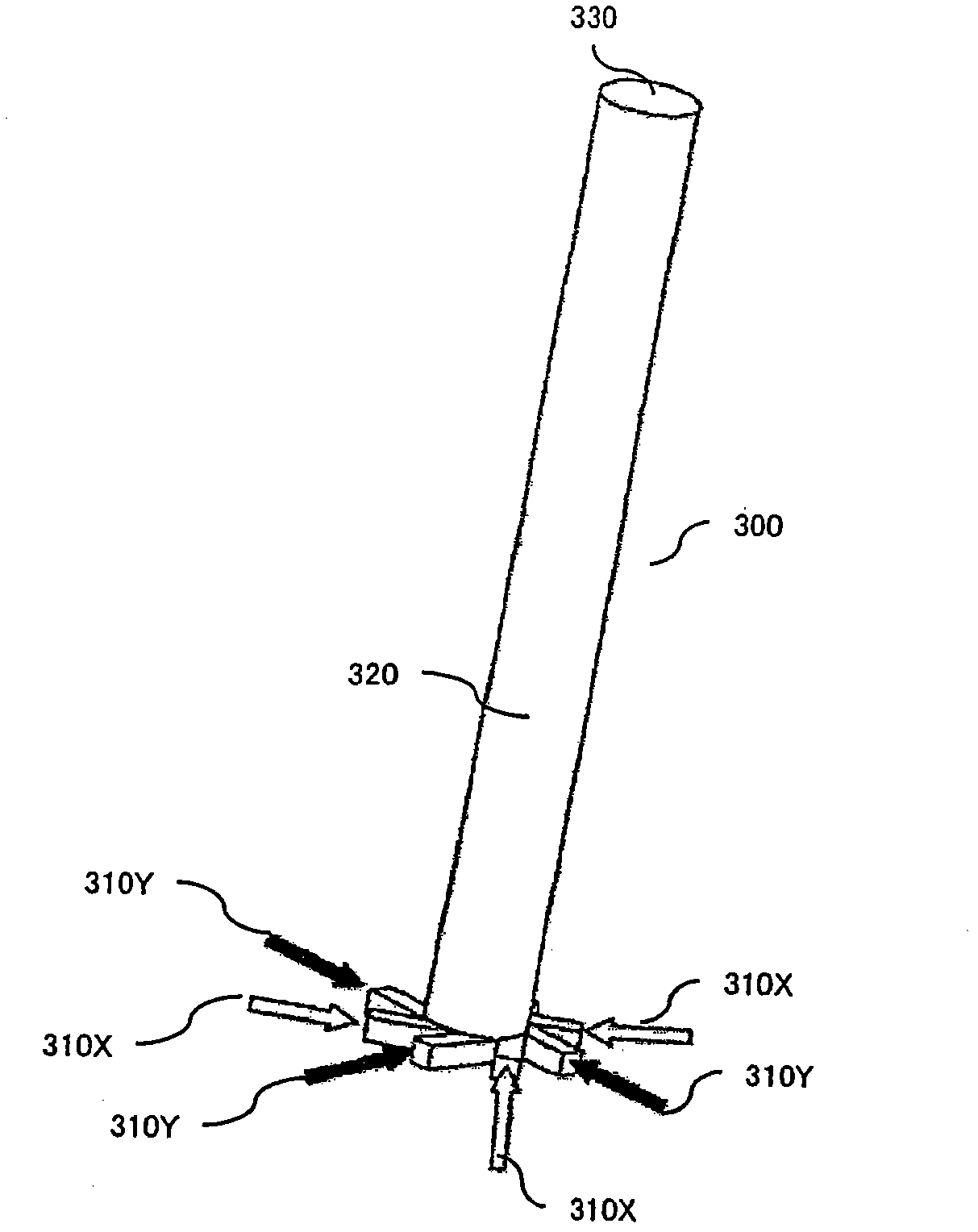

[0078] image 3 A perspective view showing the reaction device of the present invent...

no. 2 approach

[0091] Figure 9 It is a perspective view of one embodiment of the reaction apparatus of the present invention using a swirling flow, Figure 10 Indicates its front view and top view. In the case of a small reaction device in which the inner diameter of the mixing channel 320 is 1 cm or less, eight first and second inlet channels 310X and 310Y cannot be connected. In the reaction device of this embodiment, a total of four first inlet channels 310X and second inlet channels 310Y are alternately connected so as to be rotated by 90° around the central axis of the mixing channel 320 . It should be noted that, although not shown in the figure, the total number of first and second inlet channels 310X, 310Y may be six. Compared with the conventional T-shaped tube and the reaction device using two swirling flows in the inlet flow path, the mixing property can be improved.

no. 3 approach

[0093] Figure 11 It is a perspective view of one embodiment of the reaction apparatus of the present invention using a swirling flow, Figure 12 Indicates its front view and top view. In the reaction device of this embodiment, the end of the cylindrical mixing channel 320 is sealed, and the sealed end is connected to the first inlet channel 310X and the second inlet channel 310Y, and the first inlet channel 310X The second inlet channel 310Y is used to introduce the fluid containing glycerin into the mixing channel 320 , and the second inlet channel 310Y is used to introduce the fluid including supercritical water into the mixing channel 320 . The first inlet channel 310X and the second inlet channel 310Y are connected to the mixing channel 320 in a state offset by δ from the central axis of the mixing channel 320 . In addition, a plurality of the first inlet channel 310X and the second inlet channel 310Y are provided at intervals along the flow direction of the mixing chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com