Device and method for preparing high purity m/p-nitrotoluene by coupling rectification and crystallization

A technology for p-nitrotoluene and nitrotoluene, which is applied in the field of preparation devices for aromatic hydrocarbon isomer m-(p-)nitrotoluene, can solve the problems of unusable, difficult separation, poor product quality and the like, and achieves The effect of convenient operation, reasonable process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

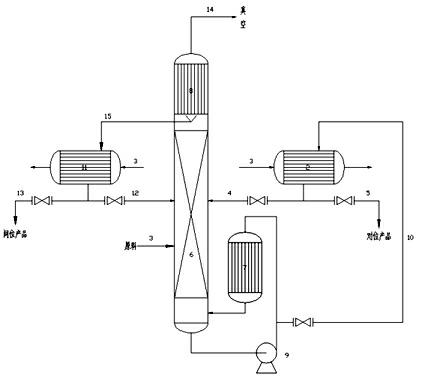

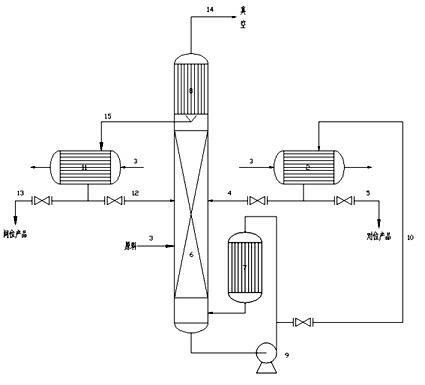

[0017] Embodiment 1: prepare p-nitrotoluene and meta-nitrotoluene according to the following steps: 1. The raw material is crude nitrotoluene, which contains ortho-nitrotoluene, para-nitrotoluene and meta-nitrotoluene Toluene, of which the boiling point of o-nitrotoluene is 222.3°C, the boiling point of m-nitrotoluene is 231.9°C, and the boiling point of p-nitrotoluene is 238.5°C, which will contain p-nitrotoluene after being separated by a vacuum distillation tower. The crude nitrotoluene mixture of toluene and m-nitrotoluene is sent to the rectification tower (6) with high-efficiency wire mesh packing inside through the raw material pipeline (1), and is evaporated by the falling film reboiler (7). The vapor-liquid phase exchange is continuously carried out in the column of the rectification tower, and a low-boiling-point steam with a high content of m-nitrotoluene is formed at the top of the tower. After the steam is condensed by the top condenser (8), part of the steam is re...

Embodiment 2

[0020] Embodiment 2: The steps are the same as in Example 1, wherein, the pressure inside the rectification tower: 125Pa, the temperature at the bottom of the rectification tower: 172°C, the temperature at the top of the rectification tower: 145°C, the mass concentration of m-nitrotoluene crystallizer feed: 92 %, m-nitrotoluene crystallizer cooling temperature: 0~10℃, p-nitrotoluene crystallizer feed mass concentration: 88%, p-nitrotoluene crystallizer cooling temperature: 5~30℃, crystallization cooling rate: 1~2℃ / hour, crystallizer sweating heating rate: 1~2℃ / hour.

Embodiment 3

[0021] Embodiment 3: The steps are the same as in Example 1, wherein, the pressure inside the rectification tower: 200Pa, the temperature at the bottom of the rectification tower: 185°C, the temperature at the top of the rectification tower: 165°C, the mass concentration of m-nitrotoluene crystallizer feed: 96 %, m-nitrotoluene crystallizer cooling temperature: 0~10℃, p-nitrotoluene crystallizer feed mass concentration: 95%, p-nitrotoluene crystallizer cooling temperature: 5~30℃, crystallization cooling rate: 1~2℃ / hour, crystallizer sweating heating rate: 1~2℃ / hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com