Device and method for purifying high-temperature-resistant resin

A purification method and purification device technology are applied in the field of purification devices for high temperature resins, which can solve the problems of high operation risk, complex equipment and high cost, and achieve the effects of simple equipment structure, simple and convenient operation, and reduced raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

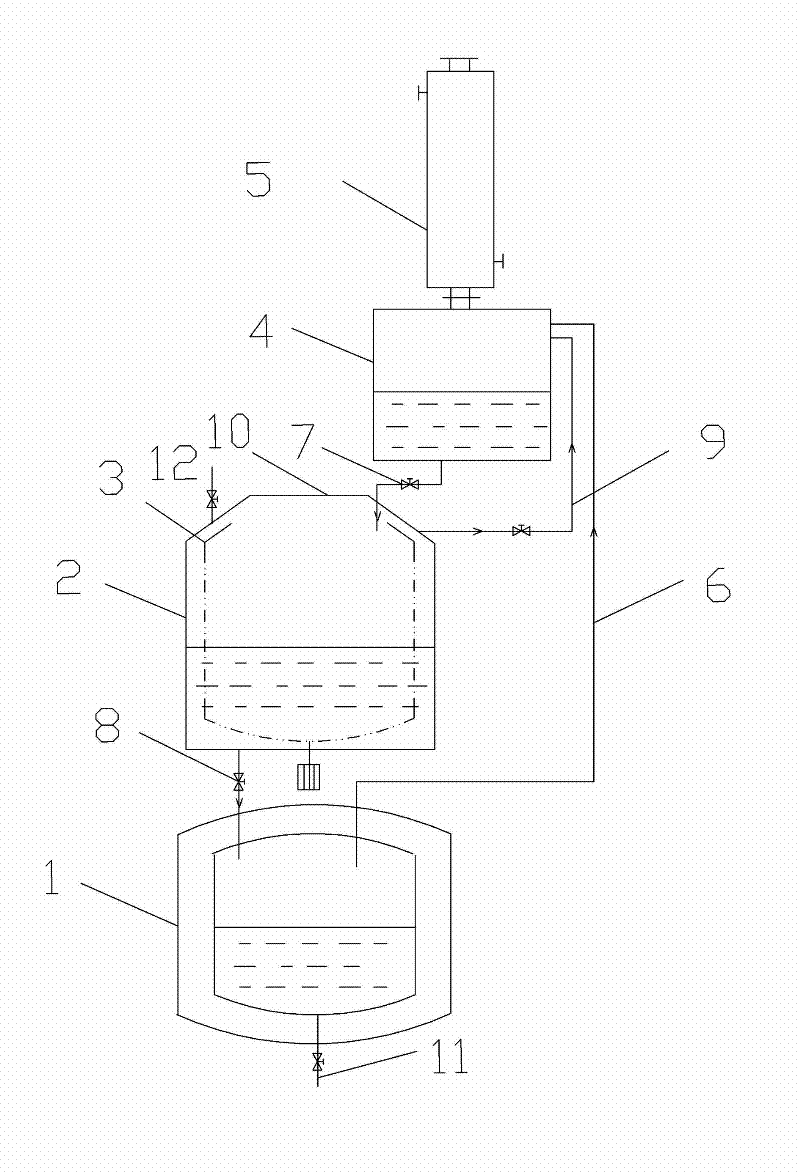

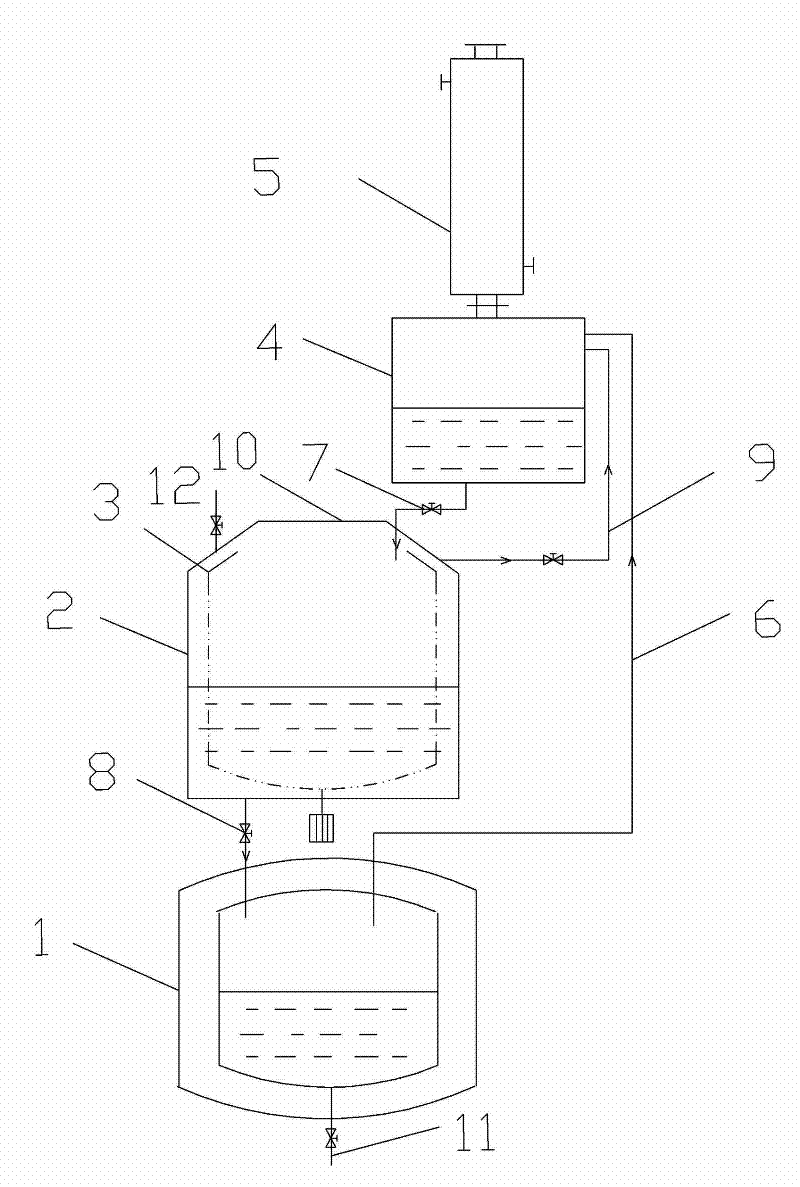

[0035] A purification device for high-temperature-resistant polymers, characterized in that the heating tank 1 is connected to the washing tank 2 through a valve 8, the washing tank 2 is equipped with a drum 3, and the lower end of the washing liquid storage tank 4 is connected through a valve 7 Washing tank 2, its upper end is connected to the loam cake of heating tank 1 through pipeline 6, the upper end of washing liquid storage tank 4 is equipped with condenser 5, and the upper end of washing tank 2 has feeding port 10. Drum 3 is a stainless steel cylinder densely covered with small holes, and the drum is lined with filter cloth. The drum can be freely rotated in the forward or reverse direction through program control; the heating tank 1 and the washing tank 2 are equipped with heating devices. Wherein the washing tank body 2 also has a vacuum device.

[0036] A method for purifying high-temperature-resistant polymers, comprising the steps of:

[0037] a) After the washin...

Embodiment 2

[0047] In order to measure the purification effect of the device of the present invention, its specific purification method is now operated, and its measurement method is Inductively Coupled Plasma Atomic Emission Spectroscopy (ICPAES) with ppm as the unit.

[0048] (1) Purification of polyether ether ketone (PEEK) resin prepared with sulfolane as solvent

[0049] Take 20kg of the above polyether ether ketone and 200kg of deionized water, put them into a washing tank, wash at 80°C, and after 40 minutes each time, centrifuge to remove most of the water, then dry the material at 130°C under vacuum to constant weight , Determination of solvent and impurity ion content in polyether ether ketone, wherein the solvent content is measured by gas chromatography analyzer, and the solvent and impurity ion content of the polymer after each washing and drying are measured as shown in Table 1.

[0050] Table 1

[0051] residue content

before processing

Process 1 time

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com