Composite material transmission tower

A technology of power transmission towers and composite materials, applied in the field of utility poles and towers, can solve the problems of high risk of anti-theft, short service life, and high thermal conductivity, and achieve the effects of long service life, reduced maintenance costs, and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

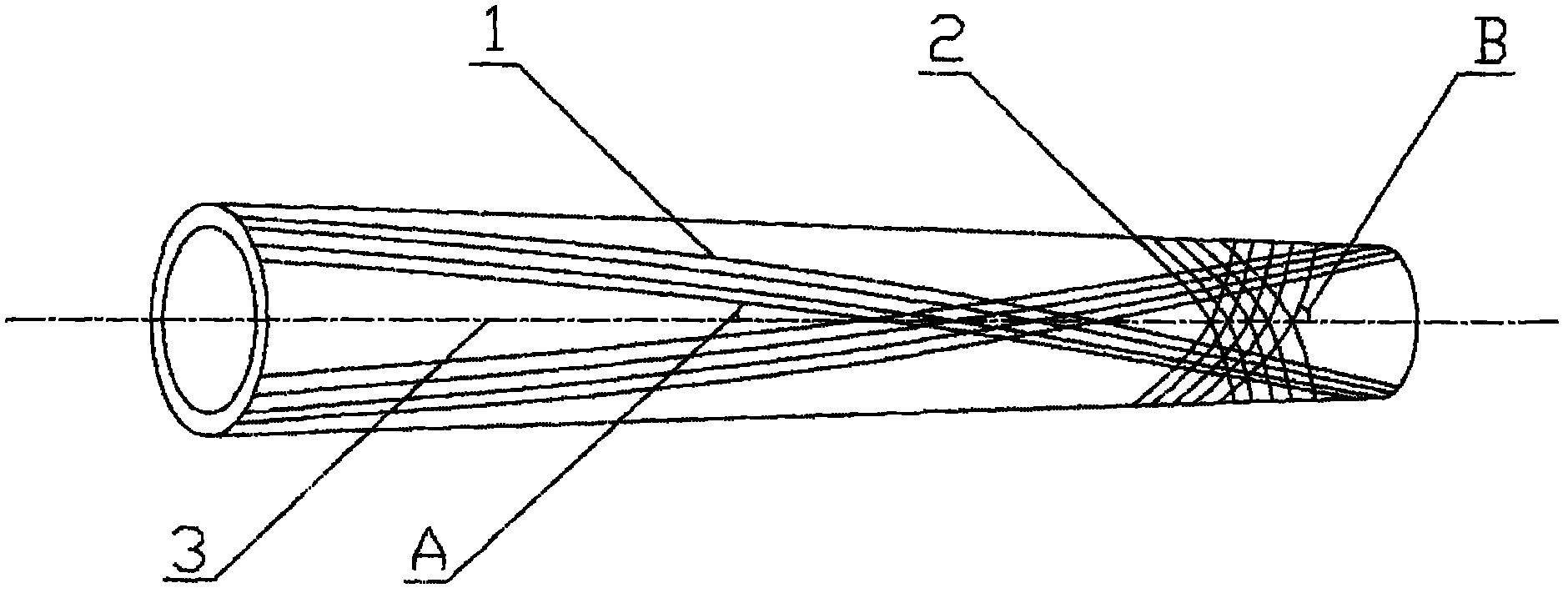

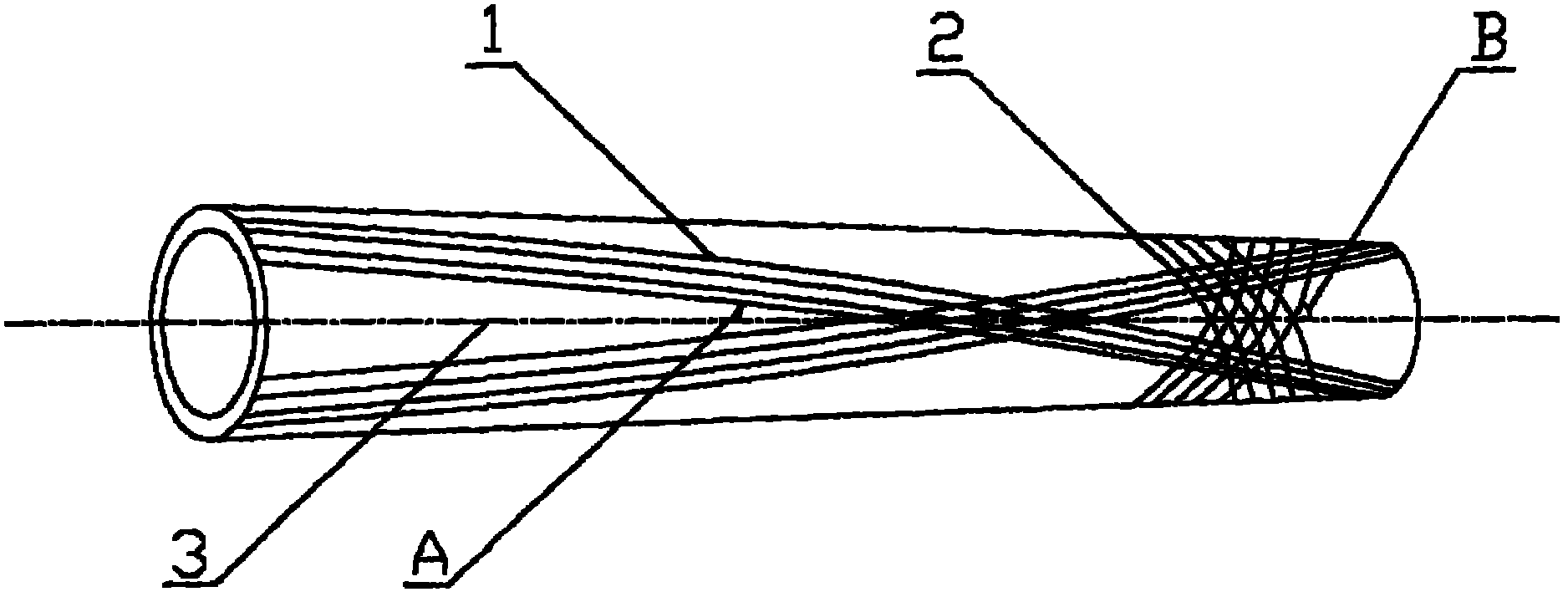

[0010] figure 1 The composite material transmission tower shown in the figure has a conical tubular structure, using thermosetting resin as the matrix, continuous glass fiber yarn as the reinforcement material, and a layer of glass fiber yarn soaked in resin is used for composite material winding process. One layer is wound on the surface of the tapered tubular mandrel. After the whole is solidified, the tapered tubular structure is formed by demolding, which is used in the field of power transmission towers. The above-mentioned glass fiber yarns are wound on the surface of the mandrel layer by layer. The angle A between a part of the glass fiber yarn 1 and the rotation axis 3 of the mandrel is 0°≤A≤15°, and the angle B between the glass fiber yarn 2 wound on the other part and the rotation axis 3 of the mandrel is 30°≤B≤ 90°, the thermosetting resin is unsaturated polyester resin, vinyl resin, epoxy resin or polyurethane resin.

[0011] The axial tensile strength of the cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com