Hydrodynamic-hydrostatic suspension mainshaft bearing

A spindle bearing, dynamic and static pressure technology, applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve the problems of machine tool machining workpiece geometric accuracy and surface finish, uneven force on the spindle, etc., to achieve large bearing capacity and wide application range Wide, strong anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

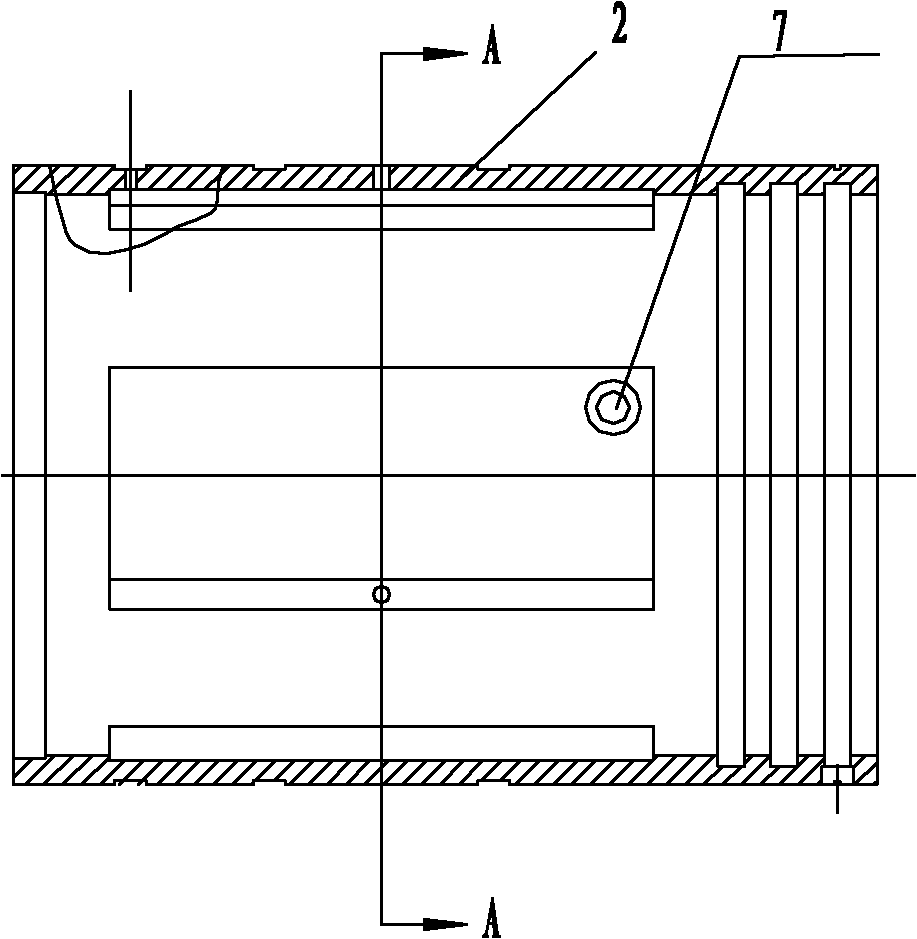

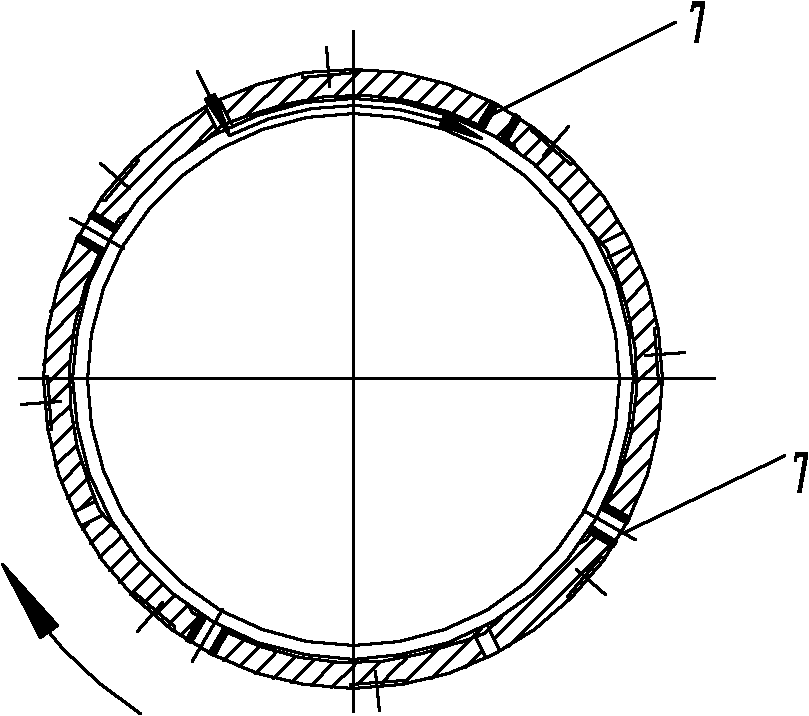

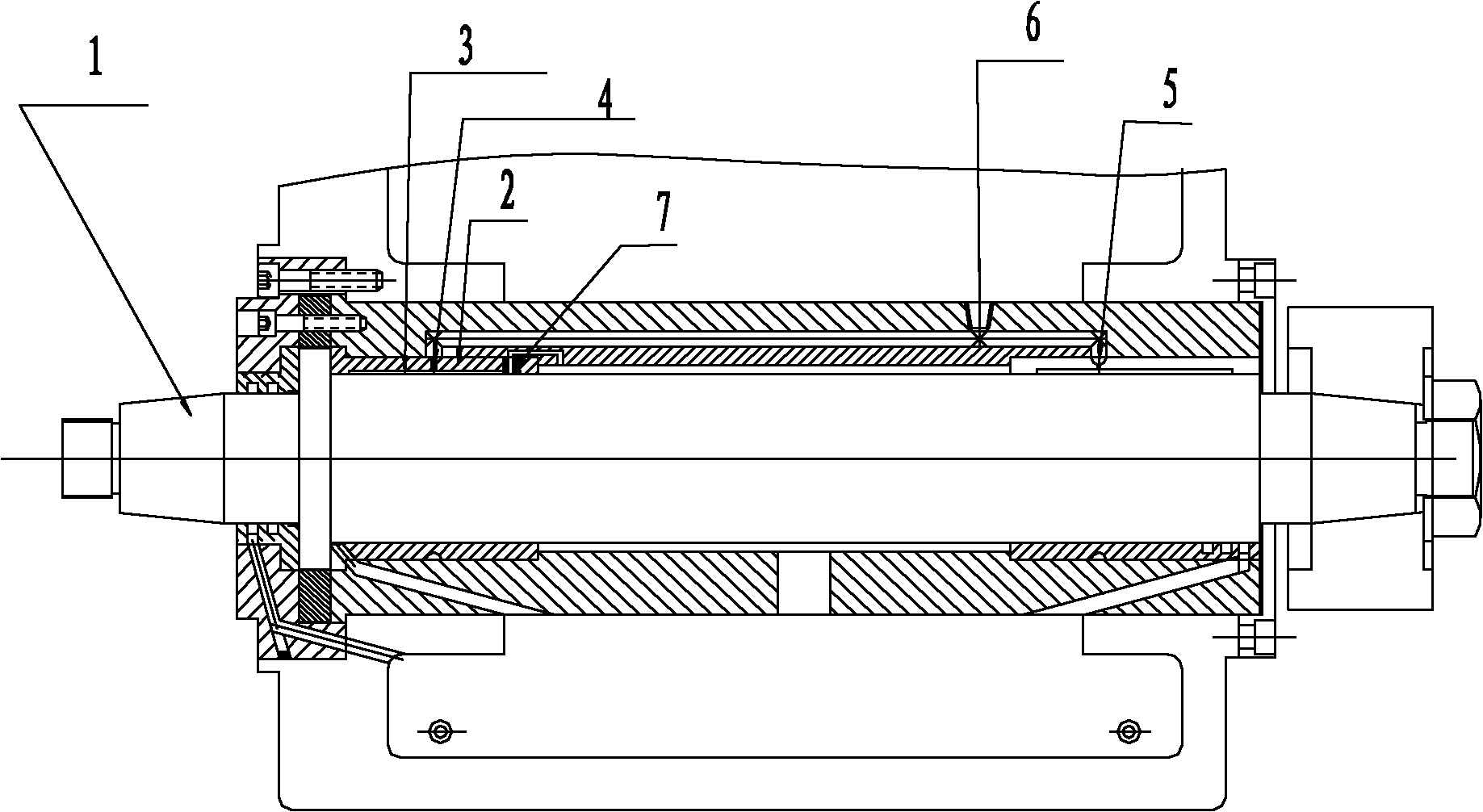

[0009] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a hydrodynamic and static suspension main shaft bearing mainly includes a main shaft 1 and a bearing 2. The bearing is provided with a number of hydrostatic oil chambers 3 on the surface opposite to the main shaft, and each hydrostatic oil chamber passes through a bearing restrictor 4 respectively. It communicates with each lubricating point pipeline 5, and each lubricating point pipeline is connected to the oil body lubrication supply system (not shown in the figure) through the bearing main pipeline 6. The static pressure oil chamber is provided with one or more overflow pressure regulators A balance hole 7, the overflow and pressure regulating balance hole communicates with the oil body lubrication supply system.

[0010] working principle:

[0011] When the main shaft rotates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com