Annealing method of rare earth-iron-aluminum alloy conductor material for cables

An iron-aluminum alloy and conductor material technology, applied in the field of wire and cable manufacturing, can solve the problems of no alloy annealing reports and patented technologies, and achieve the effects of improving crystal defects, improving crystal structure, and improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The rare earth iron and aluminum alloys contain: 0.20~1.5wt% Fe, 0.005~5wt% rare earth elements, the total impurity content is ≤0.5wt%, and the rest is Al. Rare earth elements can be composed of any one or more of the 17 elements.

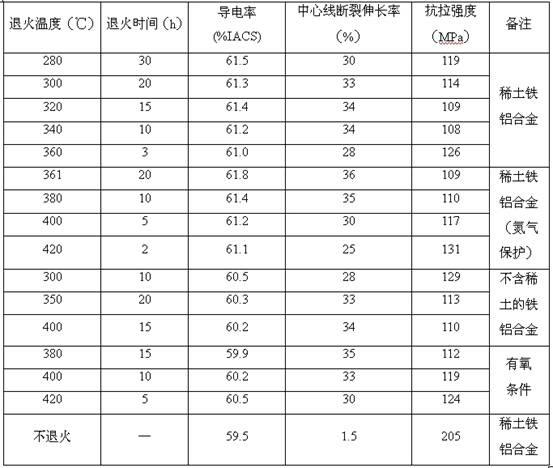

[0016] Aluminum alloy conductor core made by smelting, casting, hot rolling, cold drawing and stranding, the conductor core is annealed at 280~360℃×3~30h or at 361~420℃×2~20h , the annealing time is adjusted according to the amount of conductor cores loaded on the disk. When performing annealing treatment at 361~420℃×2~20h, the annealing furnace needs to be evacuated and filled with nitrogen for protection.

[0017] The annealing equipment used in the present invention is a well-type annealing furnace, a box-type annealing furnace, a trolley-type resistance furnace or a bell-type annealing furnace.

[0018] After annealing, the conductivity of the conductor core is ≥61%IACS, the elongation at break of the center line is ≥10%, and the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com