Manufacture method of EEPROM (Electronically Erasable Programmable Read-Only Memory) device

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as device failure and difficulty in adjusting the threshold voltage of low-voltage devices, so as to simplify the process steps and enhance the adjustable threshold voltage sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

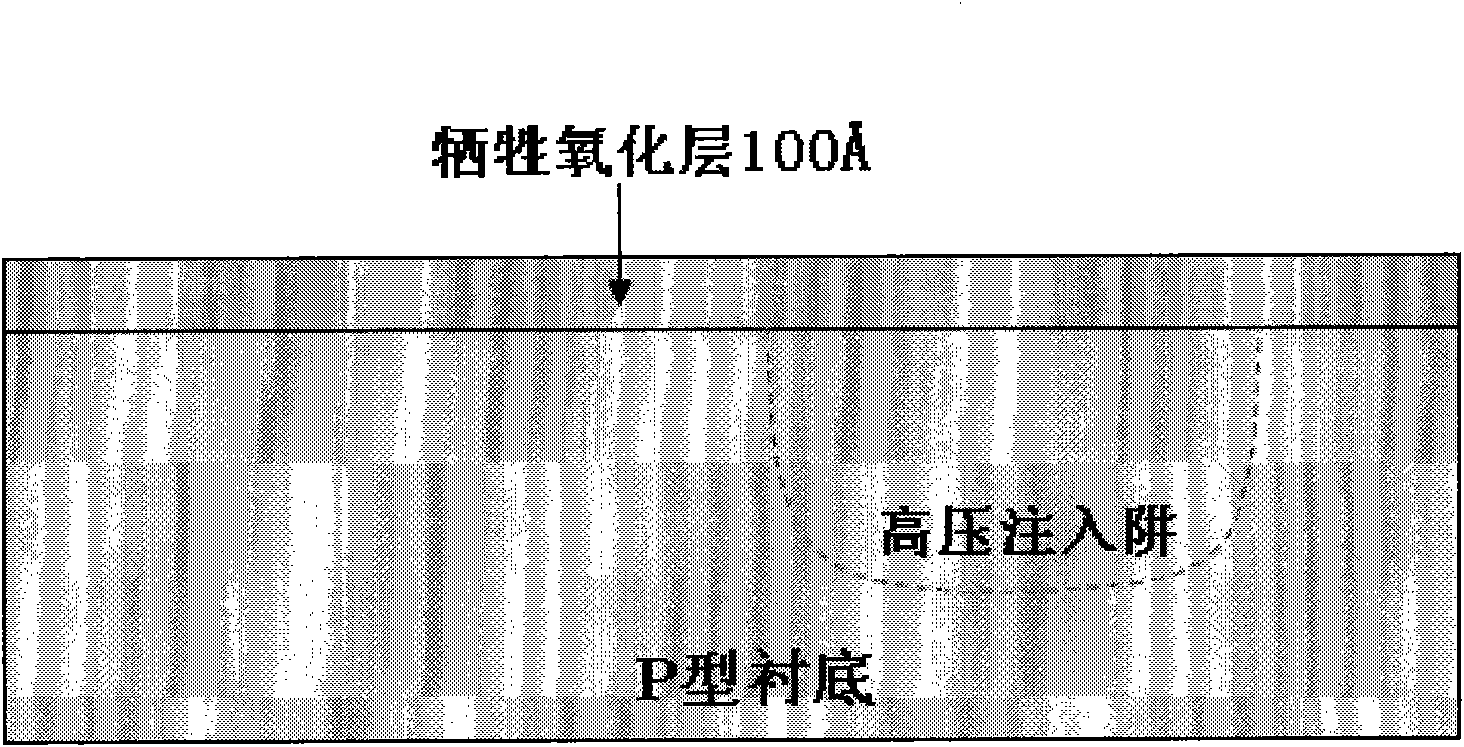

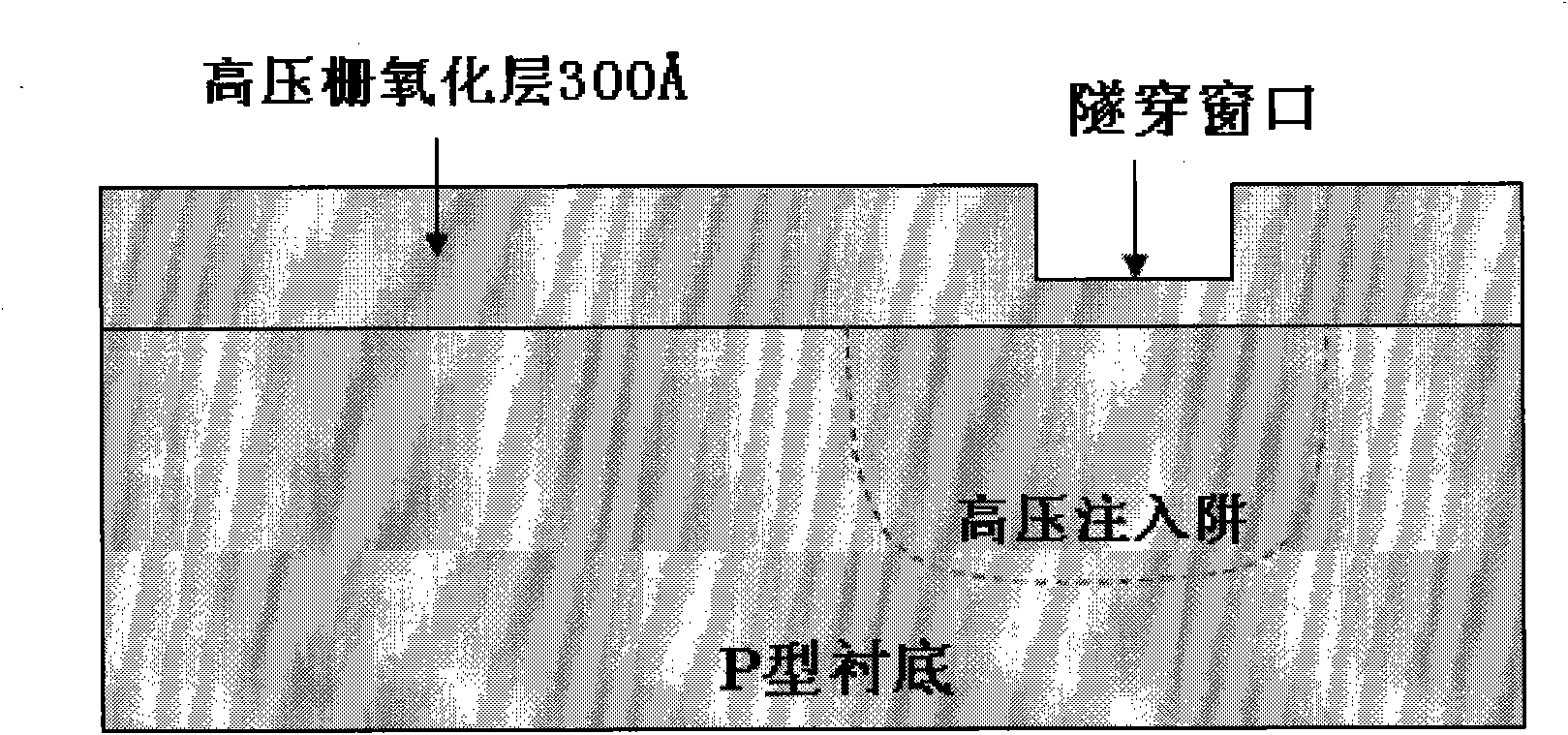

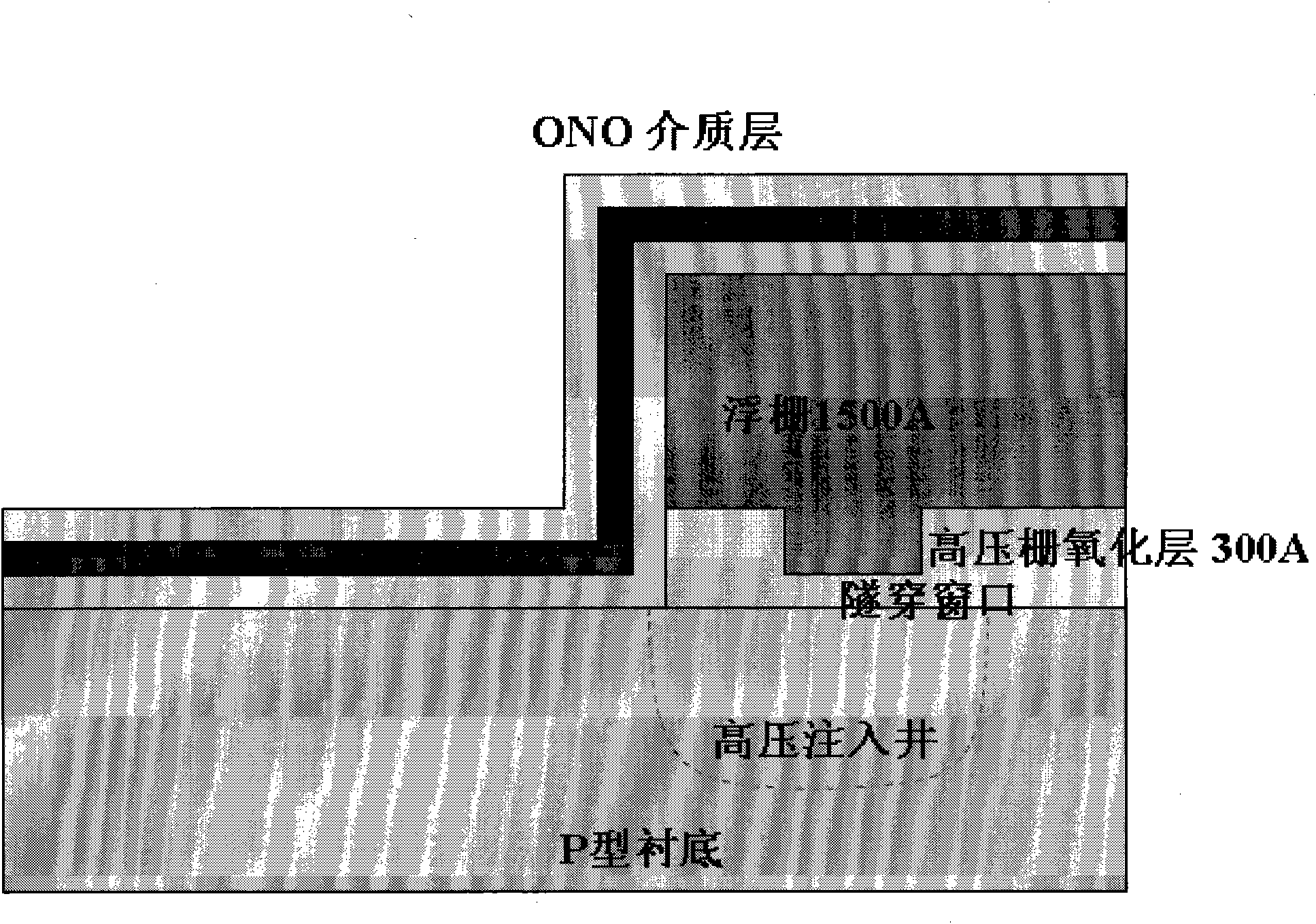

[0017] The invention provides a method for making an EEPROM device, such as Figure 1 to Figure 5 As shown, which in turn includes the following steps:

[0018] First, grow a layer of sacrificial oxide layer for high-pressure well injection to form high-pressure well injection;

[0019] Then, removing the sacrificial oxide layer, growing a high voltage gate oxide layer, and forming a tunneling window;

[0020] Afterwards, the floating gate is deposited, the floating gate is etched in the logic area, and the ONO dielectric layer is deposited, and the silicon oxide layer and the middle silicon nitride layer of the ONO dielectric layer are etched away in the logic area, and the remaining The underlying silicon oxide layer;

[0021] Finally, the silicon oxide layer at the bottom of the ONO dielectric layer that has not been etched away in the logic area is used as a sacrificial oxide layer for low-pressure well injection to form low-pressure well injection and manufacture low-vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com