Self-heating deicing system of high-tension transmission lines

A technology of high-voltage transmission lines and high-voltage transmission lines, which is applied to the installation of electrical components, cables, and the shape of heating elements, etc., which can solve the problems of high insulation strength between heating cores and transmission cores, and solve capacity limitations and reduce insulation. Requirements, avoiding the effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

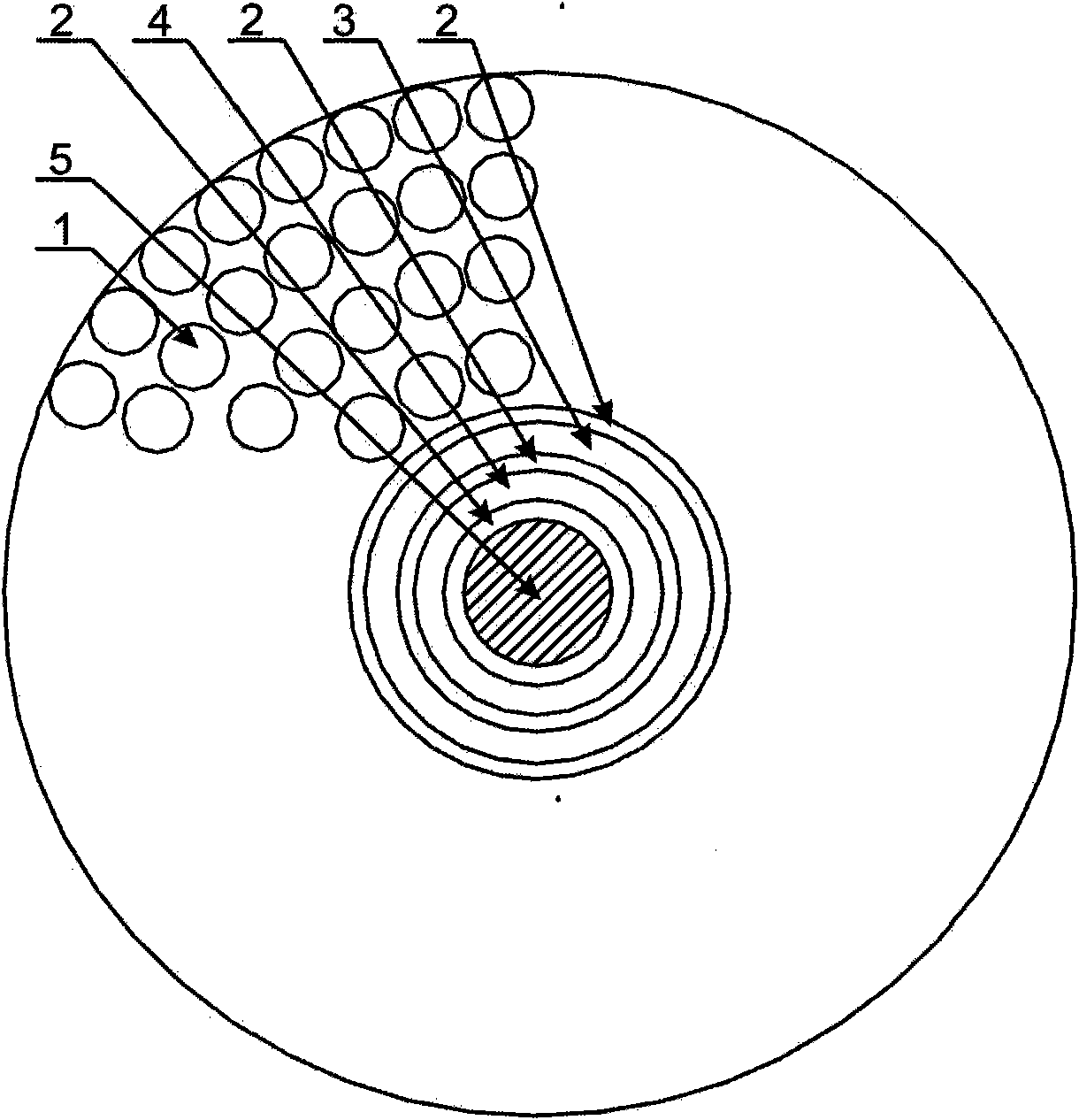

[0037] Such as image 3 As shown, the scheme uses an external DC power supply, and forms a deicing circuit through the transmission line core and the heating line core in the transmission cable, and the two ends of the transmission line core and the heating line core are respectively connected by short-circuit equalizing lines; The power transmission cable is also provided with a bypass core, which is used to control the deicing of the ice-covered section of the line; by switching the switch in the deicing current circuit, the deicing work only needs to Part of the line covered with ice, or in the case that the entire power transmission line has been covered with ice, the de-icing work mode can be used to solve the problem of the capacity limitation of the de-icing power supply.

Embodiment 2

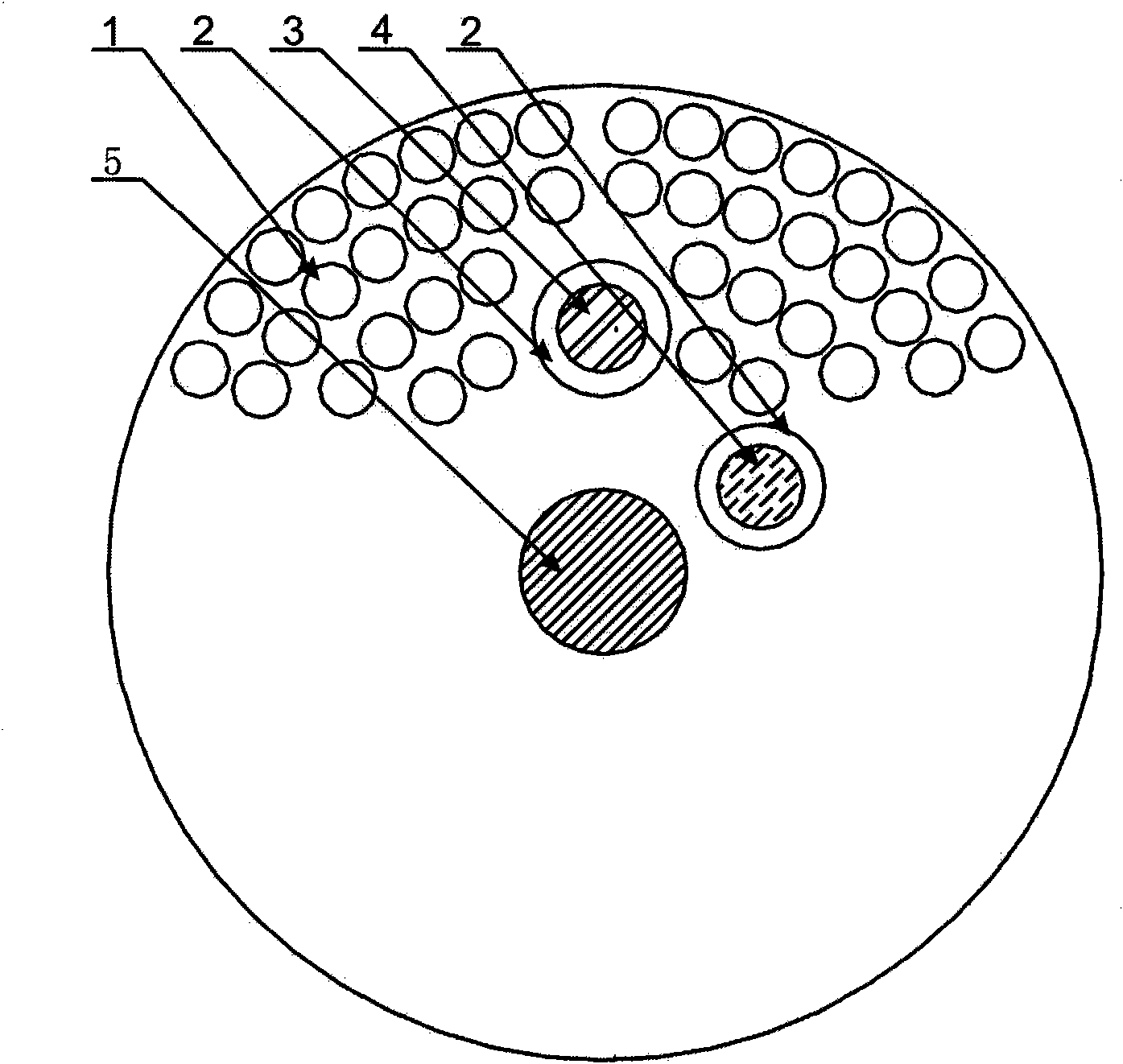

[0039] Such as Figure 4 As shown, the working current of the heating core comes from the DC power provided by the isolated power supply. A power supply device is added in the closed loop between the heating core and the parallel-connected transmission core to form a heating loop on the transmission line to achieve the purpose of melting ice. The primary side coil of the transformer is connected to the main power transmission line, and the secondary side coil of the transformer is connected to the rectifier device to provide deicing power for the deicing circuit. The purpose of segmented deicing can also be achieved by connecting a switch with address programming or remote control function in parallel.

Embodiment 3

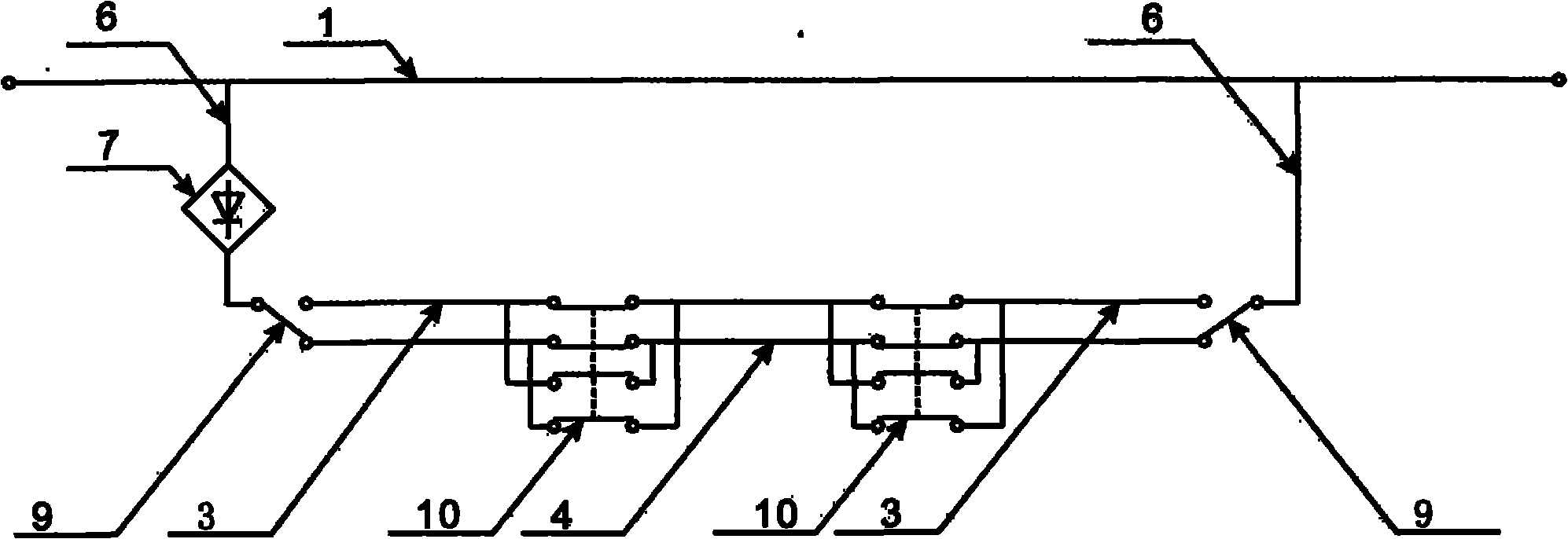

[0041] Such as Figure 5 As shown, in this scheme, a variable impedance is connected in series in the main power transmission line to realize the shunting of the power current in the main power transmission line to the deicing circuit, so as to provide power for the deicing circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com