Method for regenerating ion exchange resin of reverse osmosis rear secondary mixed bed

A technology of ion exchange resin and reverse osmosis, applied in the direction of ion exchange regeneration, ion exchange, ion exchange bed cleaning/flushing, etc., can solve the problems such as difficult to remove, achieve the effect of reducing resin consumption, simple operation, and improving effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

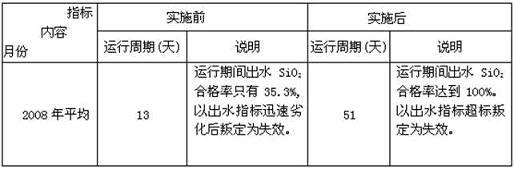

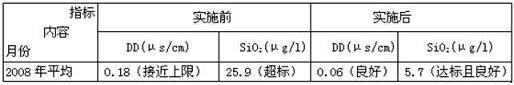

[0025] A regeneration method for secondary mixed bed ion exchange resin after reverse osmosis, the secondary mixed bed effluent SiO 2 After the index exceeds the standard (resin SiO 2 deposition poisoning), according to the following methods:

[0026] (1) The first step: after the second-stage mixed bed is out of operation, first use 0.5% low-concentration NaOH solution to pass through the mixed bed resin layer at a flow rate of 4-5m / h, and stop when the lye flows out;

[0027] (2) The second step: 1) Use 5% high-concentration NaOH solution to pass through the mixed bed resin layer at a flow rate of 4-5m / h, close the lower row when the lye flows out, soak the resin for 24 hours, and then drain the regeneration product ;

[0028] 2) Rinse with desalinated water until PH=7;

[0029] (3) The third step: 1) Backwash stratification and release water;

[0030] 2) Wash the anion resin with hot desalted water at 45°C-50°C;

[0031] 3) Perform mixed bed regeneration according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com