Vascular stent cutting device and vascular stent cutting method

A vascular stent and cutting equipment technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of backward technology, insufficient miniaturization of the system, high cost, and achieve the effect of low cost and great practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

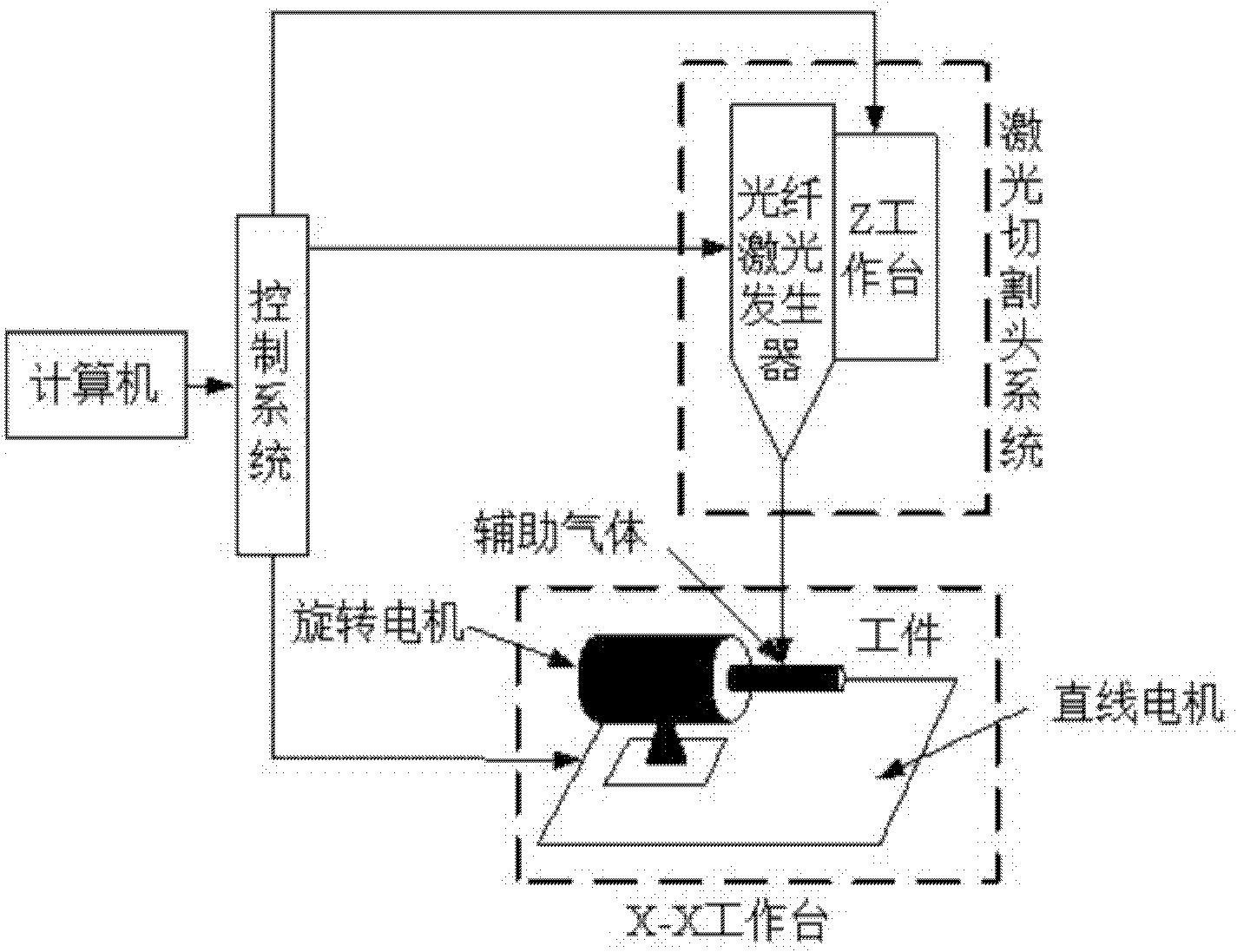

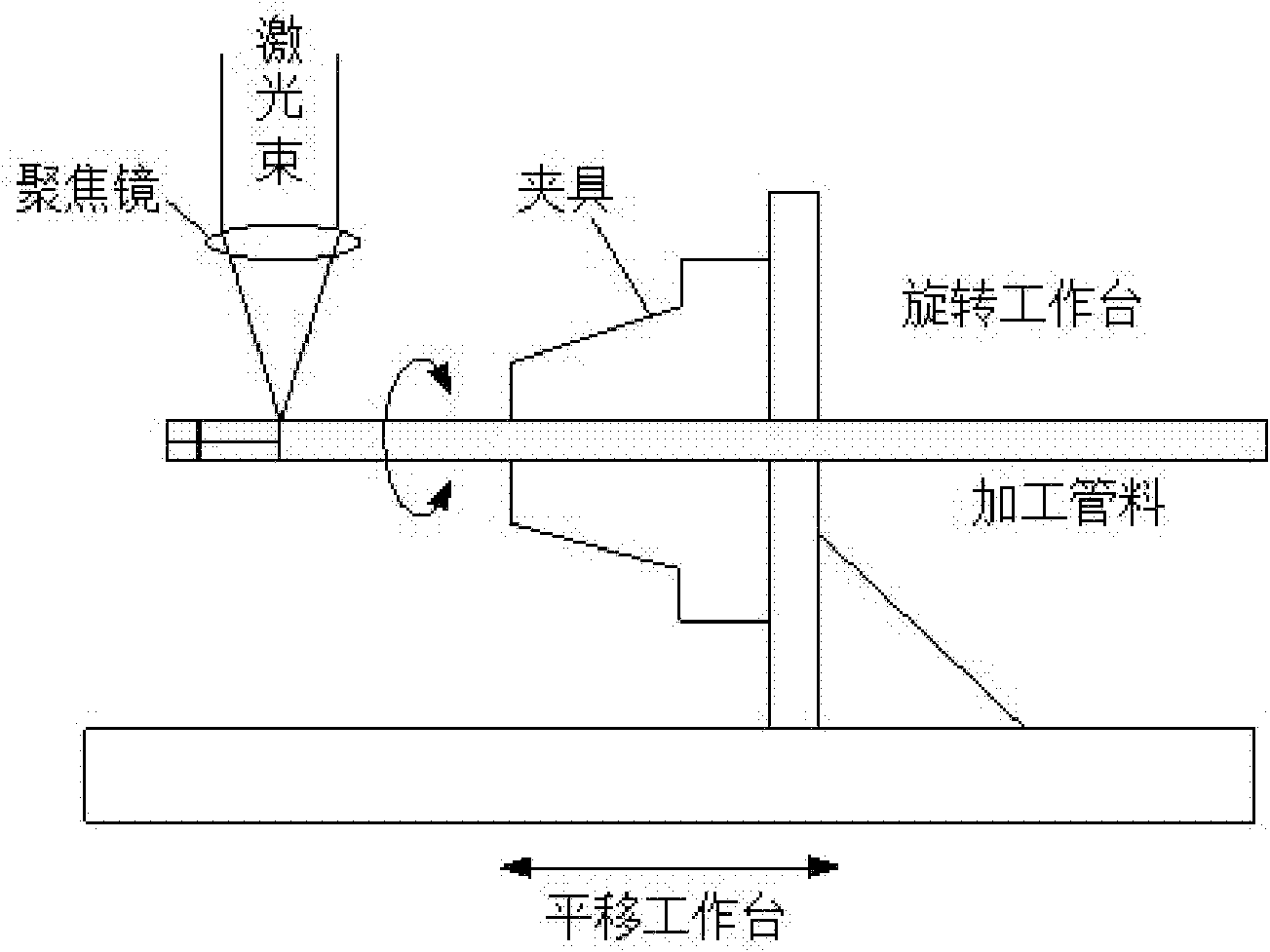

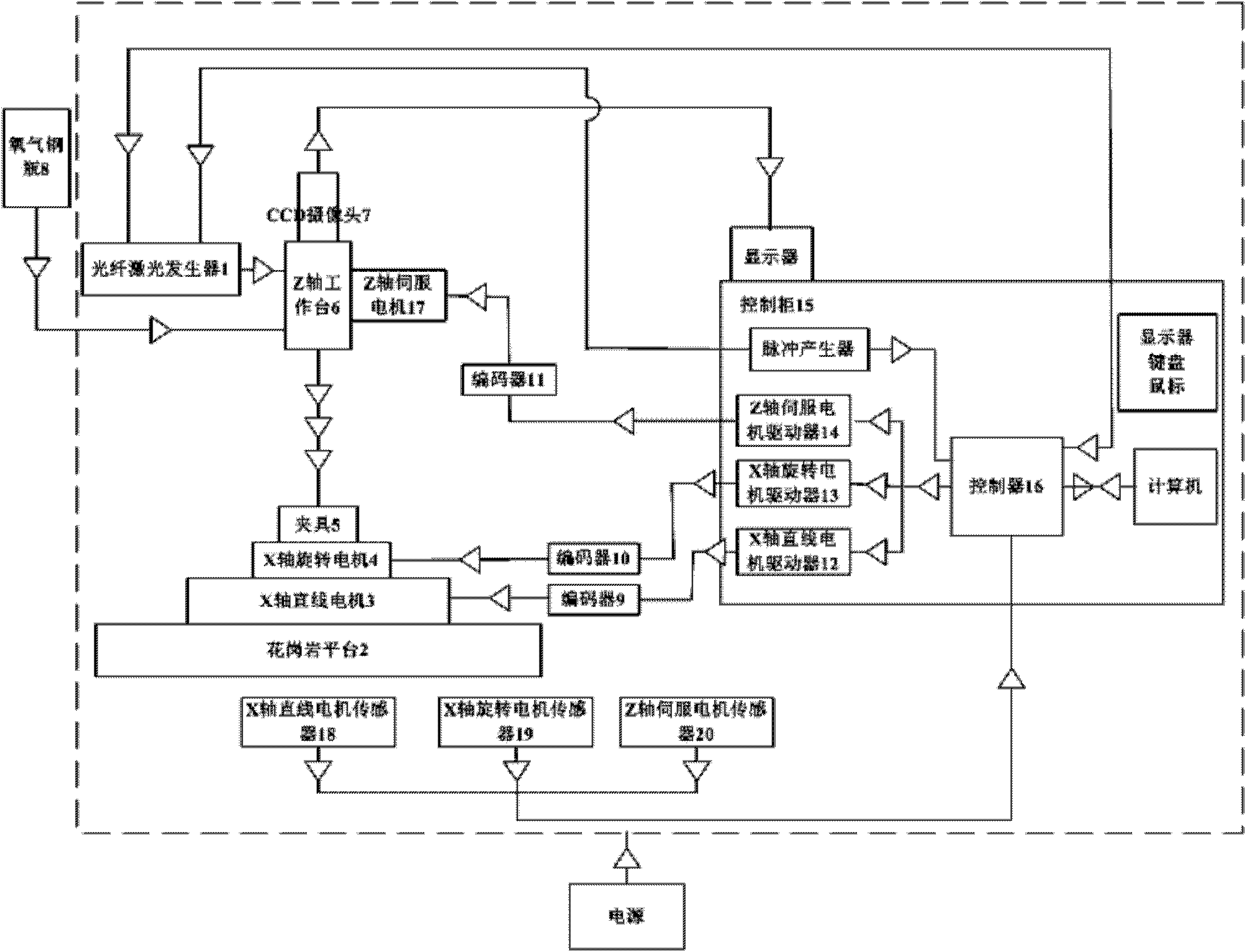

[0031] Fiber laser cutting equipment for vascular stents as shown in the accompanying drawings, including a laser cutting head system, an X-X table that can move horizontally along the X-axis and rotate around the X-axis and a granite platform with counterweight 2, the workpiece set on the rotating motor Fixture 5, the laser cutting head system includes a fiber laser generator 1, a Z table 6 that can move in the vertical direction, and the Z table 6 is a motion platform that is composed of a Z-axis servo motor 17 that can move in the vertical direction, so The laser generator 1 is installed on the Z workbench 6; the laser generator moves together with the Z workbench, and also includes a motion control part, a laser generator control part and a system controller provided with the X-X workbench and the Z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com