New method for preparing magnesium-aluminum hydrotalcite

A technology of magnesium aluminum hydrotalcite and magnesium hydroxide, which is applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of difficult washing and filtration, high reaction cost, unfavorable environmental protection, etc., and achieve high product purity and process Mature, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

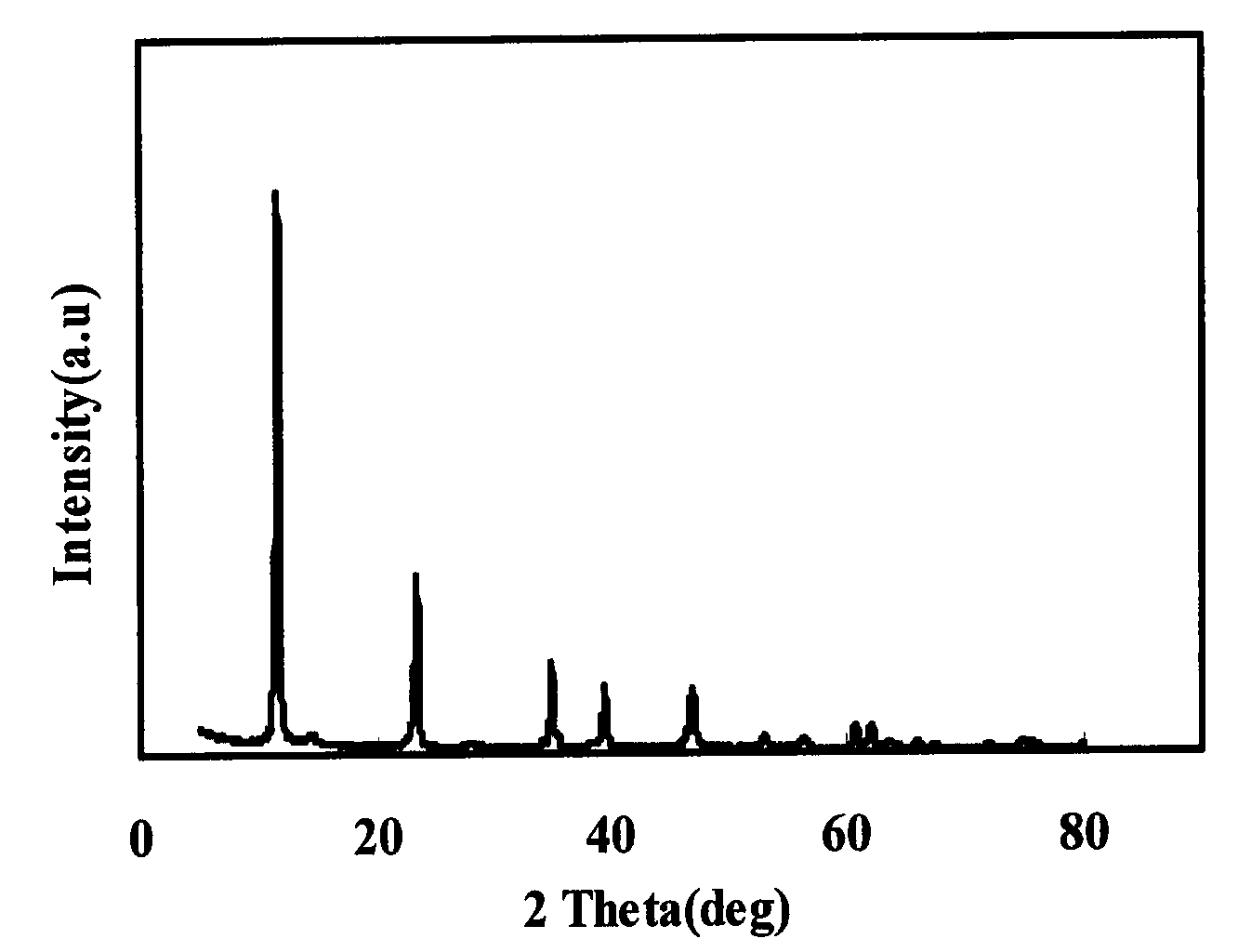

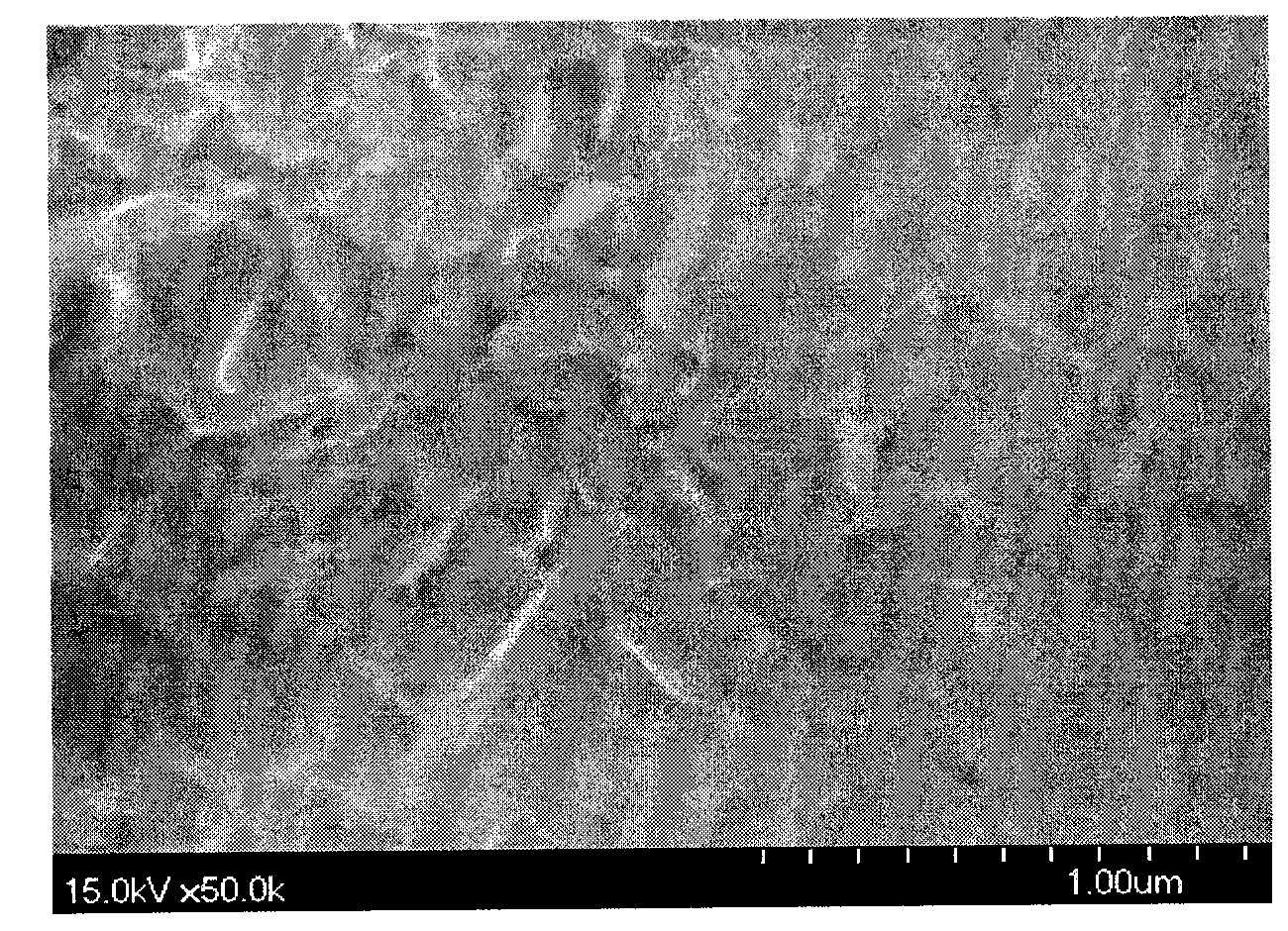

Image

Examples

Embodiment 1

[0028] Take a 500mL three-neck flask, add 160mL of 0.5mol / L aluminum chloride solution, add dropwise 120mL of 2mol / L ammonia water at 60°C, filter and wash twice after the addition, put the gelatinous aluminum hydroxide into 1L Take another 500mL three-neck flask, add 100mL of 2mol / L magnesium chloride solution, add 200mL of 2mol / L ammonia water dropwise at 60°C, filter and wash twice to obtain superfine magnesium hydroxide, and Magnesium was put into a 1L reaction kettle for later use; another 500mL three-neck flask was taken, and 20mL of 2mol / L magnesium chloride solution was added, and 40mL of 2mol / L ammonia water was added dropwise at 60°C. Carbon dioxide gas until the magnesium hydroxide is completely dissolved. Pour the clear solution into the above-mentioned 1L reaction kettle, cover and stir at 60°C for 2h, then add a surface modifier for modification, stir for 1h, and dry with a spray dryer.

Embodiment 2

[0030] Take a 500mL three-neck flask, add 160mL of 0.5mol / L aluminum nitrate solution, add 120mL of 2mol / L ammonia water dropwise at 70°C, filter and wash twice after the addition, put the gelatinous aluminum hydroxide into 1L of reaction Take another 500mL three-neck flask, add 100mL of 2mol / L magnesium chloride solution, add 200mL of 2mol / L ammonia water dropwise at 70°C, filter and wash twice to obtain superfine magnesium hydroxide, and Put it in a 1L reaction kettle for later use; take another 500mL three-neck flask, add 20mL of 2mol / L magnesium chloride solution, add 40mL of 2mol / L ammonia water dropwise at 70°C, filter and wash after the addition, add a small amount of water to stir, and pass through carbon dioxide Gas until the magnesium hydroxide is completely dissolved. Pour the clear solution into the above-mentioned 1L reaction kettle, cover and stir at 70°C for 2 hours, then add a surface modifier for modification, stir for 1 hour, and dry with a spray dryer.

Embodiment 3

[0032] Take a 500mL three-necked flask, add 160mL of 0.5mol / L aluminum chloride solution, add dropwise 120mL of 2mol / L ammonia water at 90°C, filter and wash twice after the addition, put the gelatinous aluminum hydroxide into 1L Take another 500mL three-neck flask, add 100mL of 2mol / L magnesium chloride solution, add 200mL of 2mol / L ammonia water dropwise at 90°C, filter and wash twice to obtain superfine magnesium hydroxide, and Put the magnesium into a 1L reaction kettle for later use; take another 500mL three-neck flask, add 20mL of 2mol / L magnesium chloride solution, add 2mol / L ammonia water 40mL dropwise at 90°C, filter and wash after the dropwise addition, add a small amount of water to stir, and pass Carbon dioxide gas until the magnesium hydroxide is completely dissolved. Pour the clear solution into the above-mentioned 1L reaction kettle, cover and stir at 90°C for 2 hours, then add a surface modifier for modification, stir for 1 hour, and dry with a spray dryer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com