Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of difficult overlapping capacitance, difficulty in patterning gates, etc., and achieve the effect of reducing overlapping capacitance and small device size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

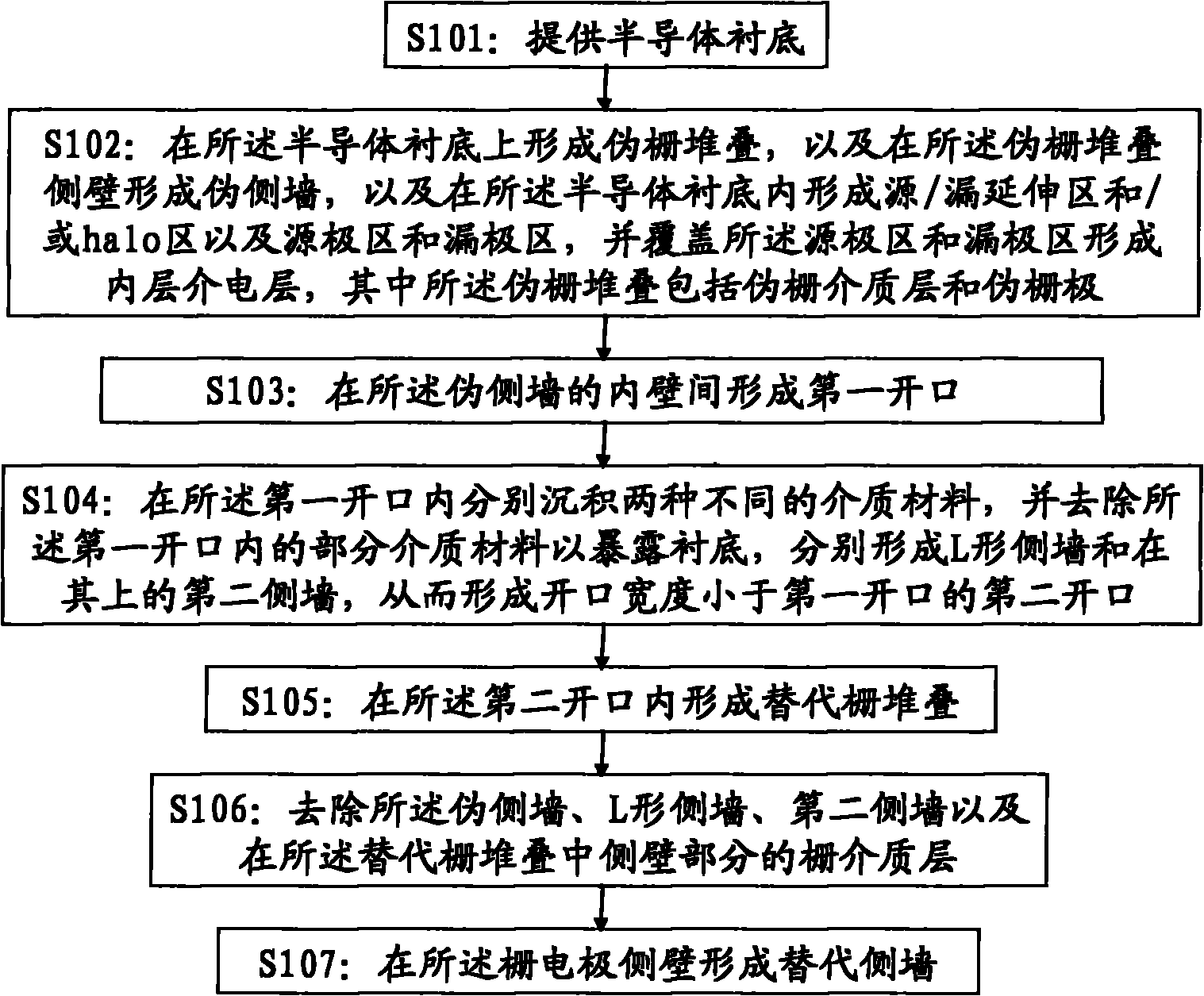

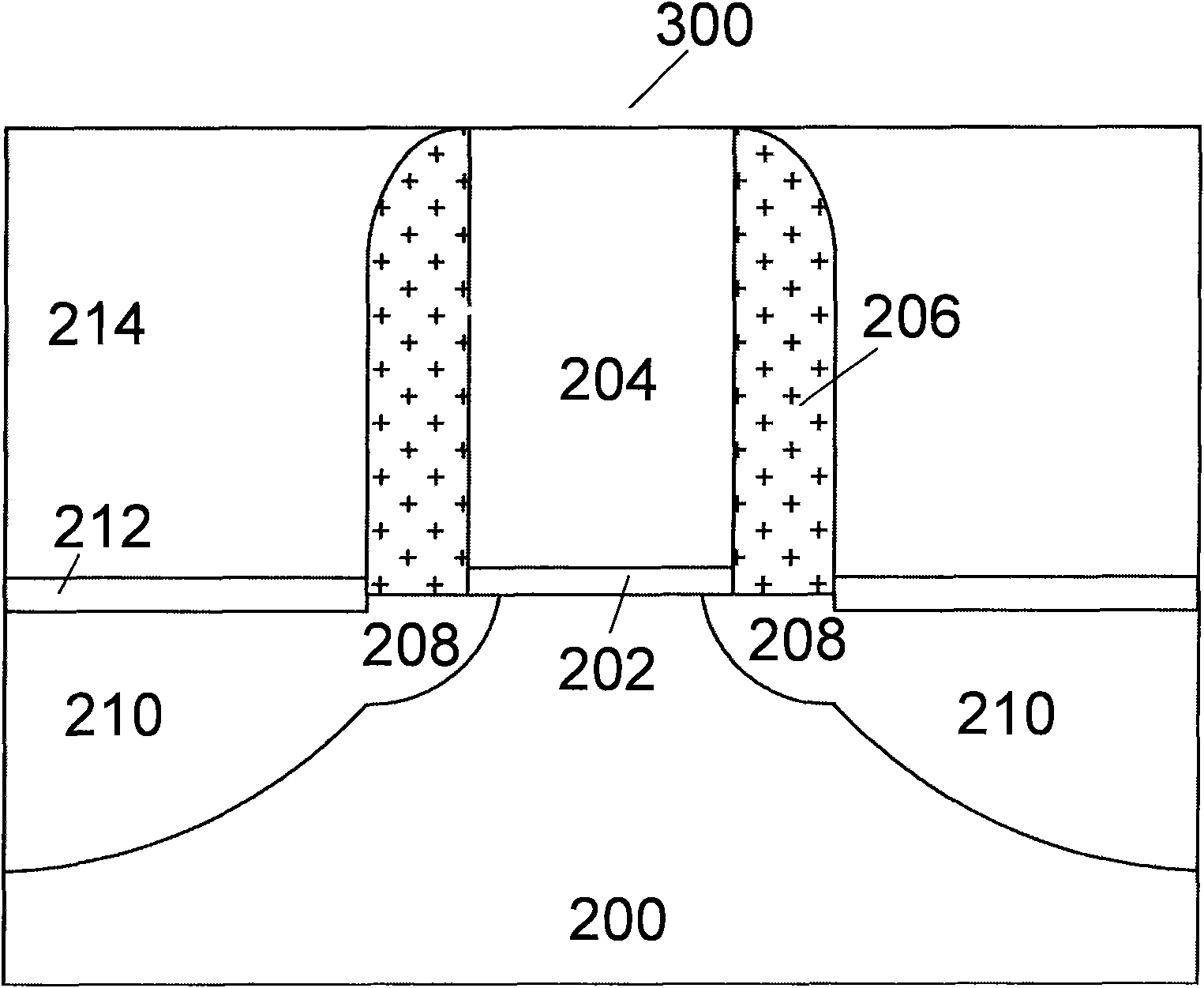

[0013] According to the first embodiment of the present invention, refer to figure 1 , figure 1 A flowchart showing a method of manufacturing a semiconductor device according to an embodiment of the present invention. In step S101, a semiconductor substrate is provided, referring to figure 2 . In this embodiment, the substrate 200 includes a silicon substrate (such as a wafer) in a crystal structure, and may also include other basic semiconductors or compound semiconductors, such as Ge, GeSi, GaAs, InP, SiC, or diamond. The substrate 200 may include various doping configurations according to design requirements known in the art (eg, p-type substrate or n-type substrate). Furthermore, the substrate 200 may optionally include epitaxial layers, may be altered by stress to enhance performance, and may include a silicon-on-insulator (SOI) structure.

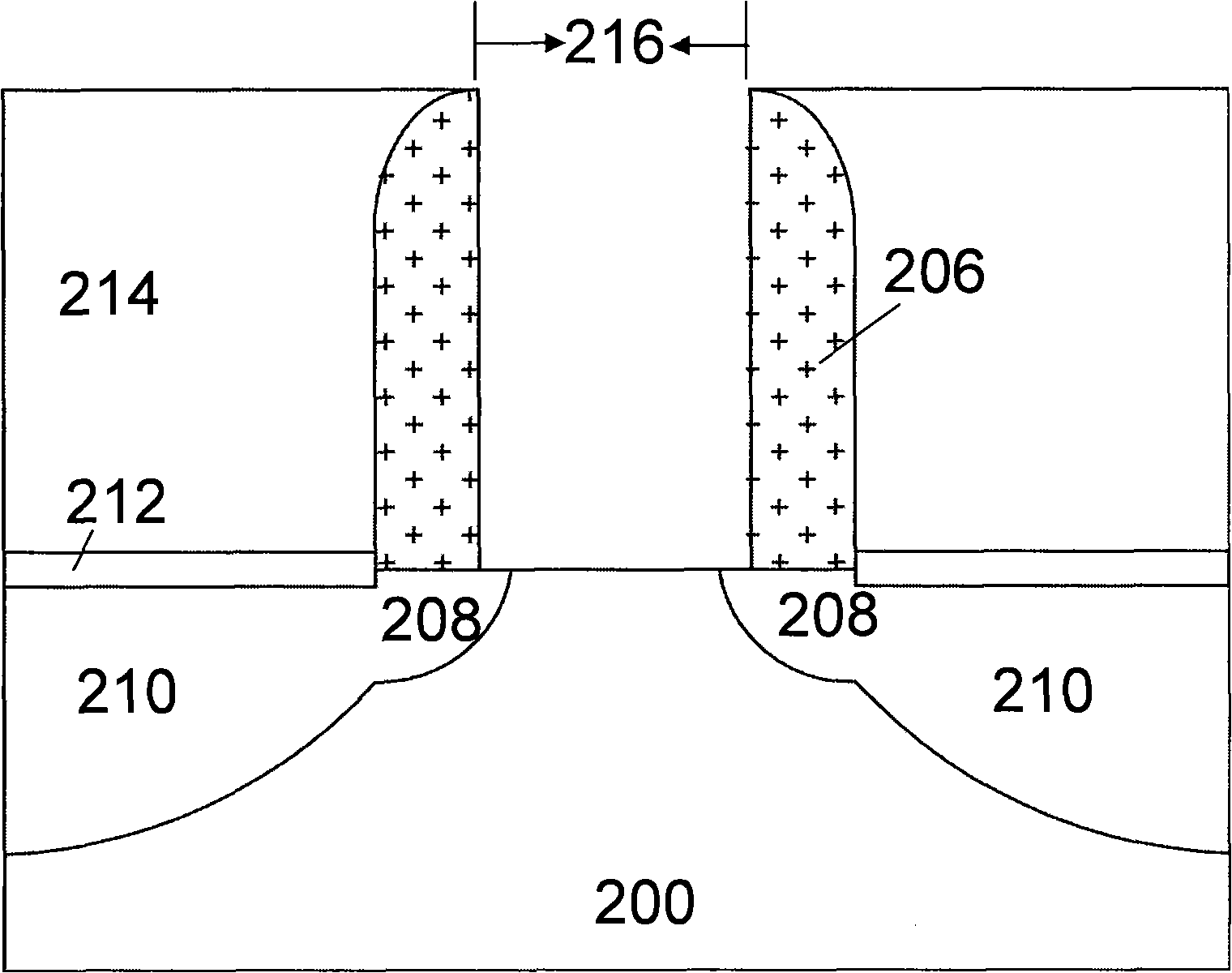

[0014] In step S102, a dummy gate stack 300 is formed on the semiconductor substrate 200, a dummy spacer 206 is formed on the s...

no. 2 example

[0027] Only the aspects of the second embodiment that differs from the first embodiment will be described below. Parts not described should be considered to be performed using the same steps, methods or processes as those in the first embodiment, so details will not be repeated here.

[0028] refer to Figure 9 , Figure 9 A flow chart showing a method for manufacturing a semiconductor device according to a second embodiment of the present invention, steps S201 to S204 according to the second embodiment of the present invention are the same as steps S101 to S104 in the first embodiment, It is considered that the same steps, methods or processes are used as those in the first embodiment, and details are not repeated here.

[0029] In step S205, the second side wall 220 is removed. The second side wall 220 can be removed by using the L-shaped side wall 218 as a stop layer by means of RIE, thereby forming the second opening 222 whose opening width is smaller than that of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com