Supported platinum catalyst for fuel cell and preparation method thereof

A platinum catalyst and fuel cell technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of poor electrocatalytic performance, unfavorable large-scale application, unfavorable electrocatalysis, etc., and achieve easy scale The effect of production, good long-term stability, and high Pt utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing a supported platinum catalyst for a fuel cell, comprising the following steps:

[0039] a) dispersing the carrier in deionized water to obtain the first suspension;

[0040] b) adding chloroplatinic acid and formic acid to the first suspension, and ultrasonically dispersing to obtain a second suspension;

[0041] c) standing the second suspension for reaction at 10° C. to 40° C., washing and drying to obtain a supported platinum catalyst.

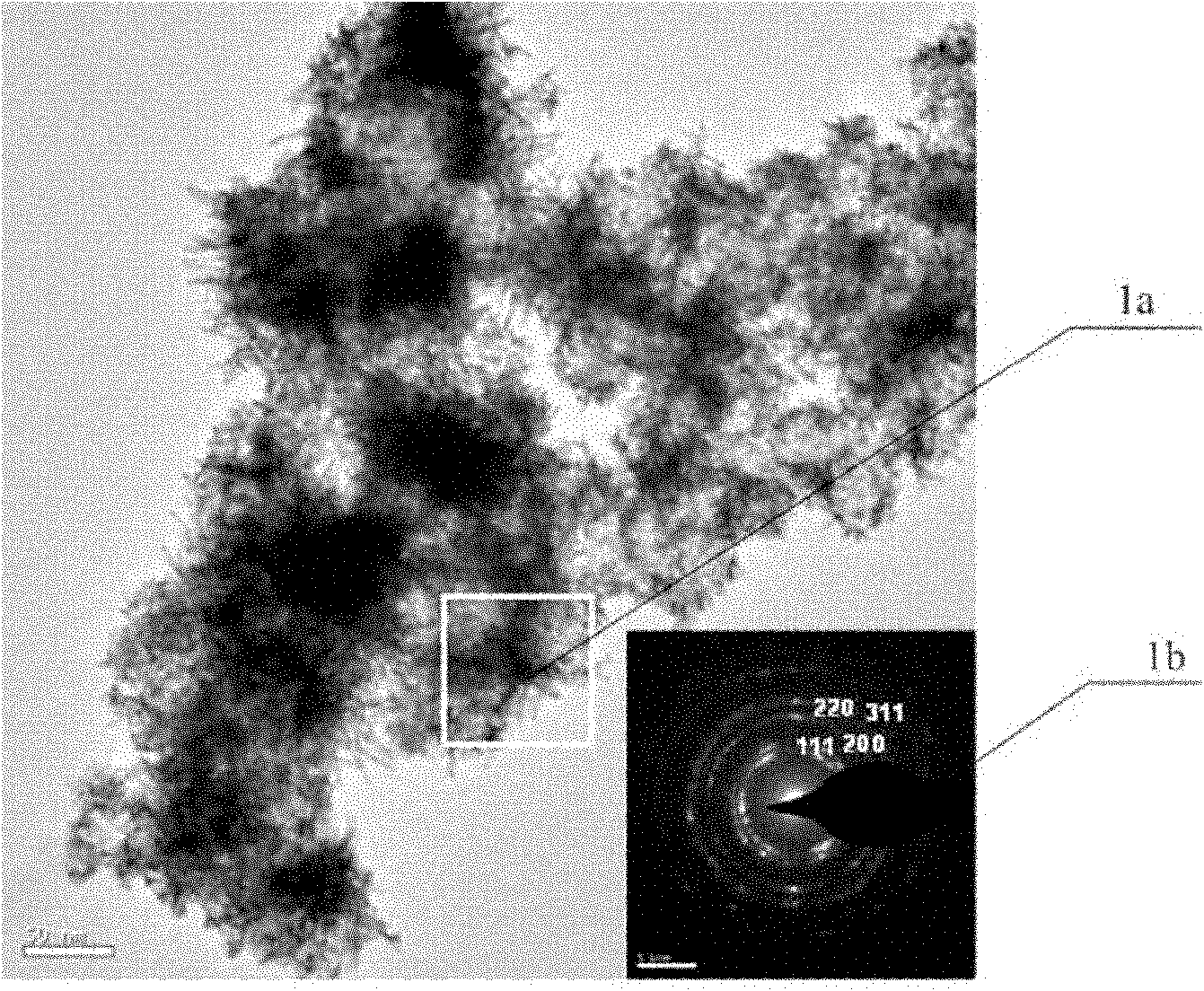

[0042] The invention uses formic acid as a reducing agent, and controls the reaction speed of formic acid and chloroplatinic acid to generate Pt atoms at a relatively slow speed, thereby realizing directional growth and obtaining a uniformly distributed and uniformly dispersed one-dimensional Pt nanowire structure.

[0043] Firstly, the carrier is dispersed in deionized water to obtain the first suspension. In the present invention, the carrier is a catalyst carrier commonly used in fue...

Embodiment 1

[0056] To 40.5mL deionized water, add 15mg of activated carbon produced by U.S. Cabot (Cabot) company, the trade name is Vulcan XC-72R, and ultrasonically disperse for 0.5h to obtain the first suspension; 6.08 mL of aqueous chloroplatinic acid solution with a concentration of 0.02 mol / L and 3 mL of formic acid with a purity of 97%, were fully dispersed and initially nucleated by ultrasonication for 0.5 h to obtain a second suspension; After standing still for 72 hours, the second suspension was suction-filtered and washed with deionized water with a resistivity of 18.2 MΩ·cm until no Cl ions existed, and the resulting suspension was vacuum-dried at 80°C to obtain a supported Platinum catalyst, the loading of platinum in the supported platinum catalyst is 60wt%.

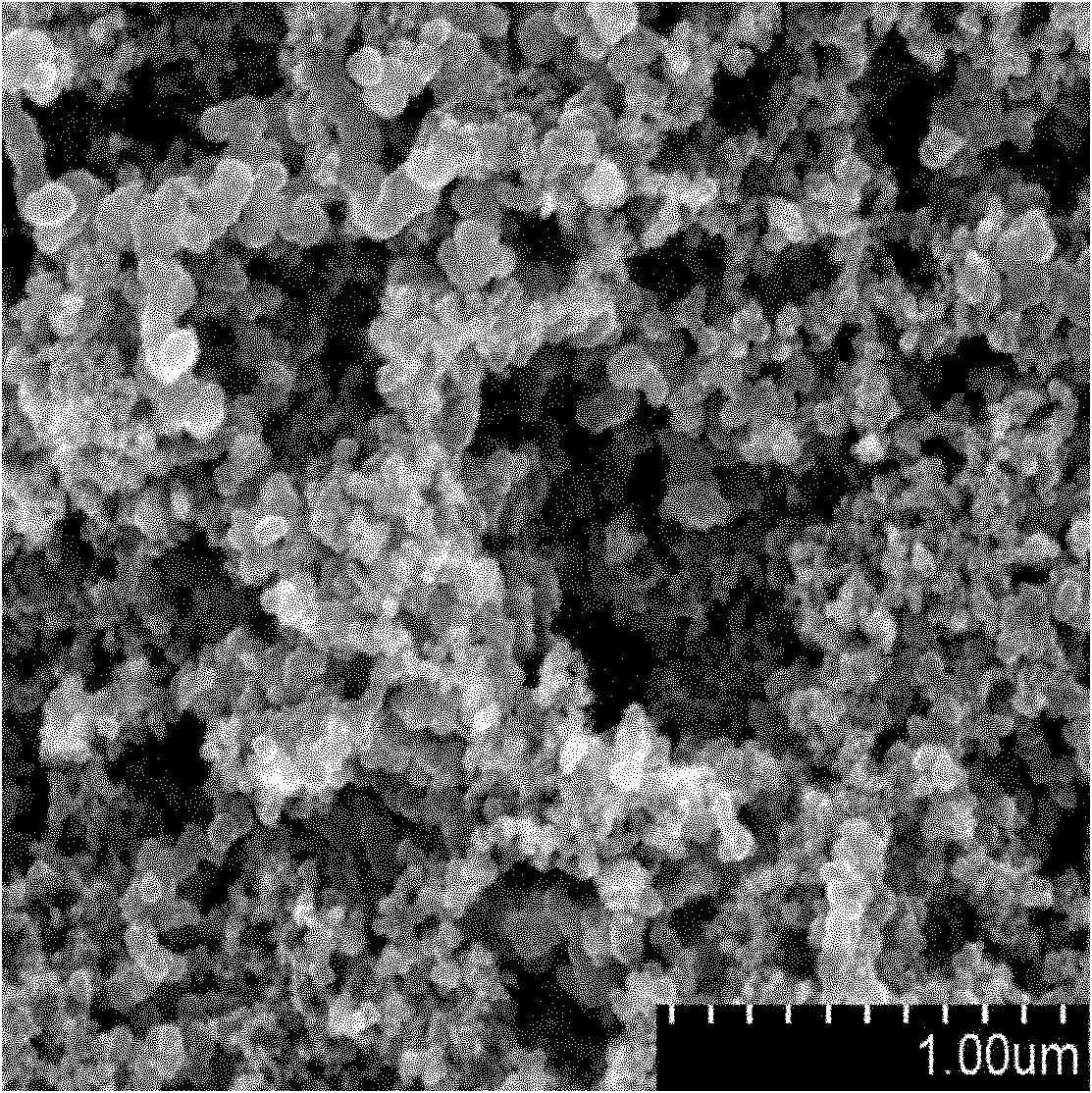

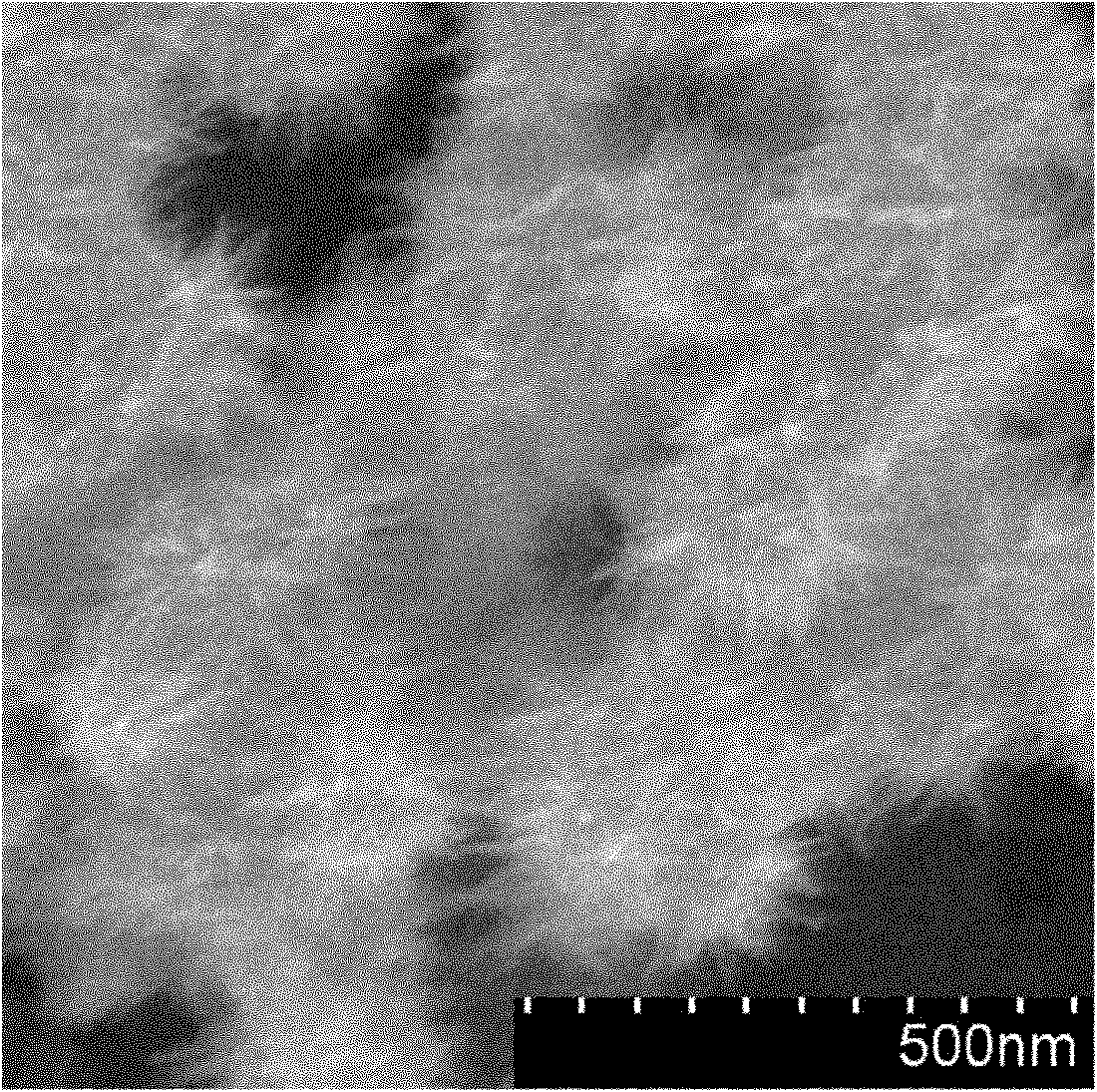

[0057] Ultrasonic disperse the supported platinum catalyst in ethanol to obtain a suspension; apply the suspension to an ITO glass and dry it, then scan it with an electron microscope, the results can be found in fig...

Embodiment 2

[0064] To 40.5mL of deionized water, add 15mg of activated carbon produced by U.S. Cabot (Cabot) company, the trade name is Vulcan XC-72, and ultrasonically disperse for 0.5h to obtain the first suspension; 6.08 mL of aqueous chloroplatinic acid solution with a concentration of 0.02 mol / L and 3 mL of formic acid with a purity of 97%, were fully dispersed and initially nucleated by ultrasonication for 0.5 h to obtain a second suspension; After standing still for 72 hours, the second suspension was suction-filtered and washed with deionized water with a resistivity of 18.2 MΩ·cm until no Cl ions existed, and the resulting suspension was vacuum-dried at 80°C to obtain a supported Platinum catalyst, the loading of platinum in the supported platinum catalyst is 60wt%.

[0065] Ultrasonic disperse the supported platinum catalyst in ethanol to obtain a suspension; apply the suspension to an ITO glass and dry it, then scan it with an electron microscope, the results can be found in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com