Microwave continuous foaming plate made from tire reclaimed rubber and preparation method of microwave continuous foaming plate

A foamed board and reclaimed rubber technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of lack of continuous vulcanization and foaming production capacity, unstable product performance, low production efficiency, etc., and achieve high production efficiency and high product quality. Stable, low labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

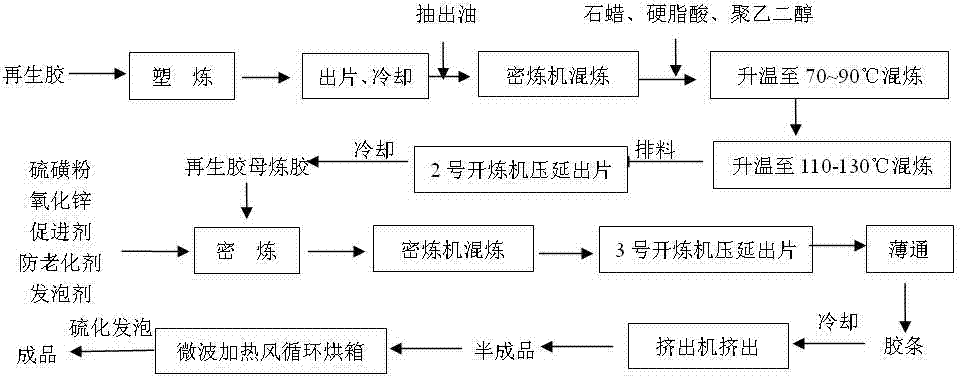

[0035] The tire reclaimed rubber microwave continuous foaming board was prepared by the following process steps.

[0036] (1) Adjust the roller distance of No. 1 mill to 0.3mm, put in the reclaimed rubber material and pass it thinly, make a triangle bag, and pass it 4 times; then adjust the roller distance of No. 1 mill to 3mm, and put in the The rubber material processed in the step is covered with rolls, and the surface is smooth and free of bubbles, and the film is lowered to make a film; the film is forced to cool to room temperature with an industrial fan, and parked for more than 24 hours;

[0037] (2) Mix the cooled film and aromatic oil according to the ratio of 8 parts of aromatic oil per 100 parts of rubber, and put it into No. 1 internal mixer for mixing, so that the reclaimed rubber and aromatic oil are fully mixed; when No. 1 internal mixer When the temperature reaches 80°C, add 0.8 parts of paraffin, 1 part of stearic acid, and 1 part of polyethylene glycol-4000 ...

Embodiment 2

[0043] The tire reclaimed rubber microwave continuous foaming board was prepared by the following process steps.

[0044] (1) Adjust the roller distance of No. 1 mill to 0.7mm, put in the reclaimed rubber material and make a triangular bag, and pass it 3 times; then adjust the roller distance of No. 1 mill to 2mm, and put in the The rubber material processed in the step is covered with rolls, and the surface is smooth and free of bubbles, and the film is lowered to make a film; the film is forced to cool to room temperature with an industrial fan, and parked for more than 24 hours;

[0045] (2) Mix the cooled film and aromatic oil according to the ratio of 12 parts of extracted oil per 100 parts of rubber, and put it into No. 1 internal mixer for mixing, so that the reclaimed rubber and aromatic oil are fully mixed; when No. 1 internal mixer When the temperature reaches 70°C, add 0.5 parts of paraffin, 0.5 parts of stearic acid, and 1.5 parts of polyethylene glycol-4000 for pr...

Embodiment 3

[0051] The tire reclaimed rubber microwave continuous foaming board was prepared by the following process steps.

[0052] (1) Adjust the roller distance of No. 1 mill to 0.5mm, put in the reclaimed rubber material and make a triangle bag, and pass it 5 times; then adjust the roller distance of No. 1 mill to 2mm, and put in the The rubber material processed in the step is covered with rolls, and the surface is smooth without air bubbles, and the film is lowered to obtain a film; the film is forced to cool to room temperature with an industrial fan, and parked for 30 hours;

[0053] (2) Mix the cooled film and aromatic oil according to the ratio of 10 parts of aromatic oil per 100 parts of rubber, and put it into No. 1 internal mixer for mixing, so that the reclaimed rubber and aromatic oil are fully mixed; when No. 1 internal mixer When the temperature reaches 85°C, add 0.5 parts of paraffin, 2 parts of stearic acid, and 1 part of polyethylene glycol-4000 in turn for pressure m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com