Method for preparing combustible gas from municipal domestic waste and plant waste

A technology for municipal solid waste and plant waste is applied in the field of preparing combustible gas, which can solve the problems of preparing combustible gas, waste land, and increase cost, and achieve the effects of simple preparation process, environmentally friendly production, and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

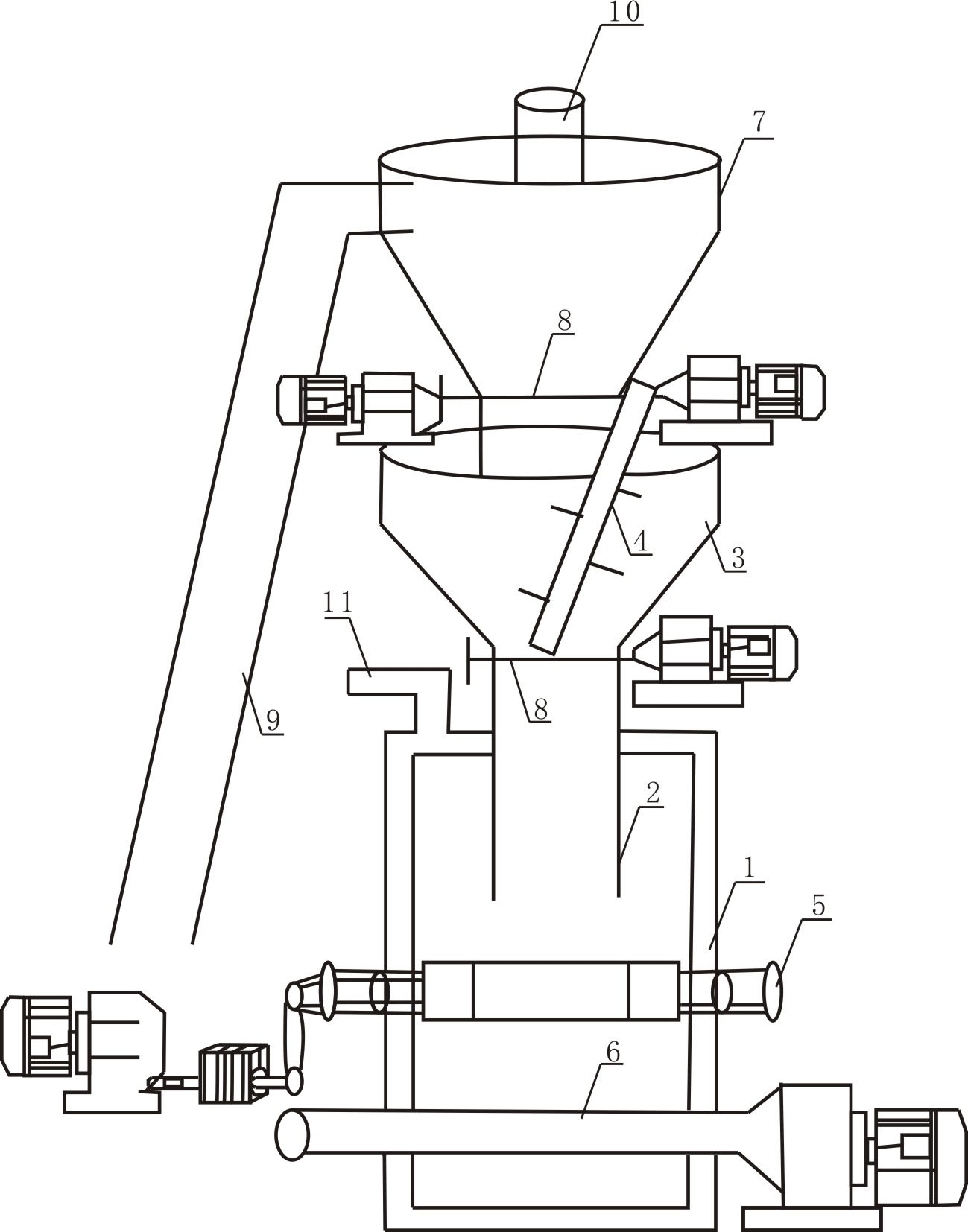

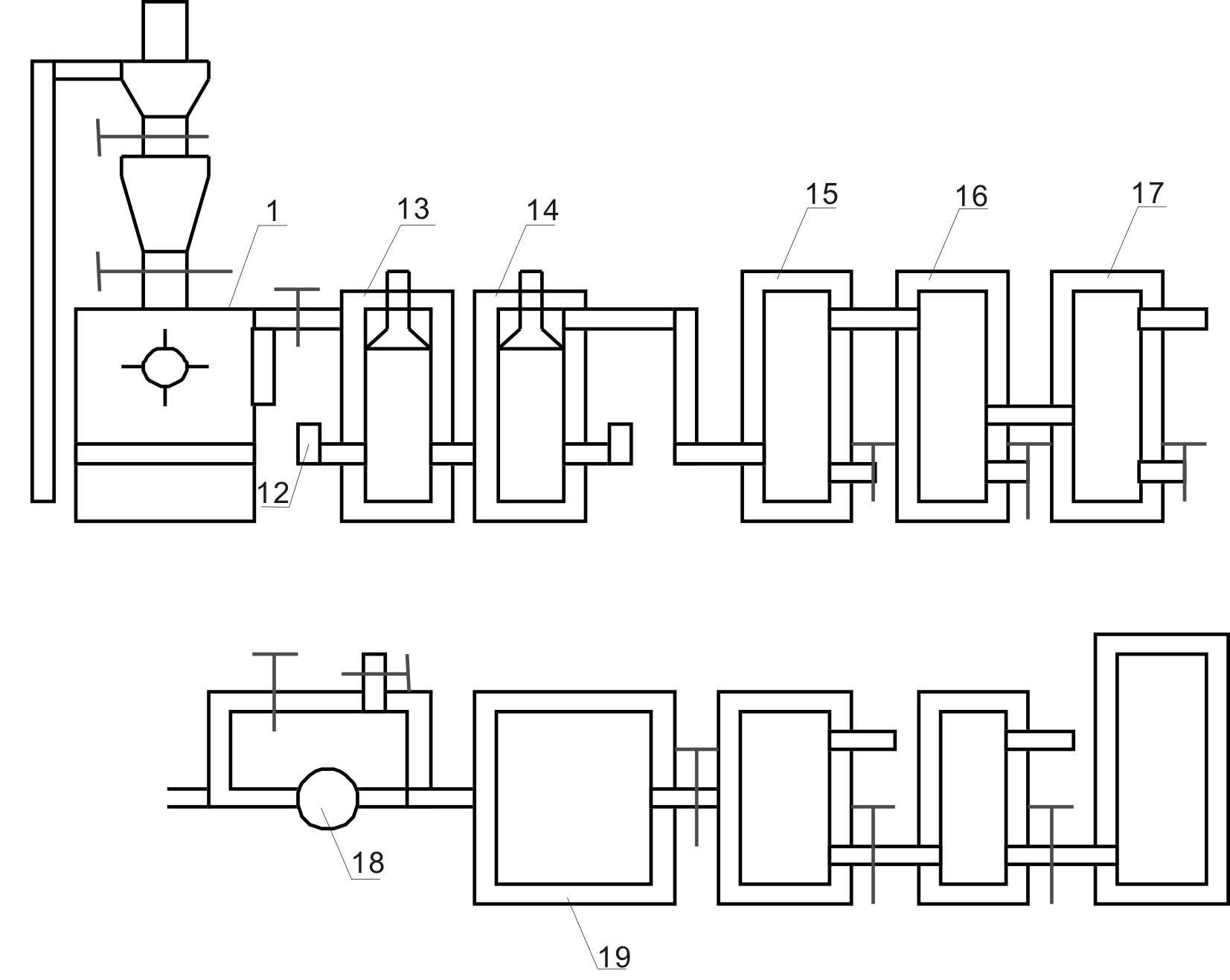

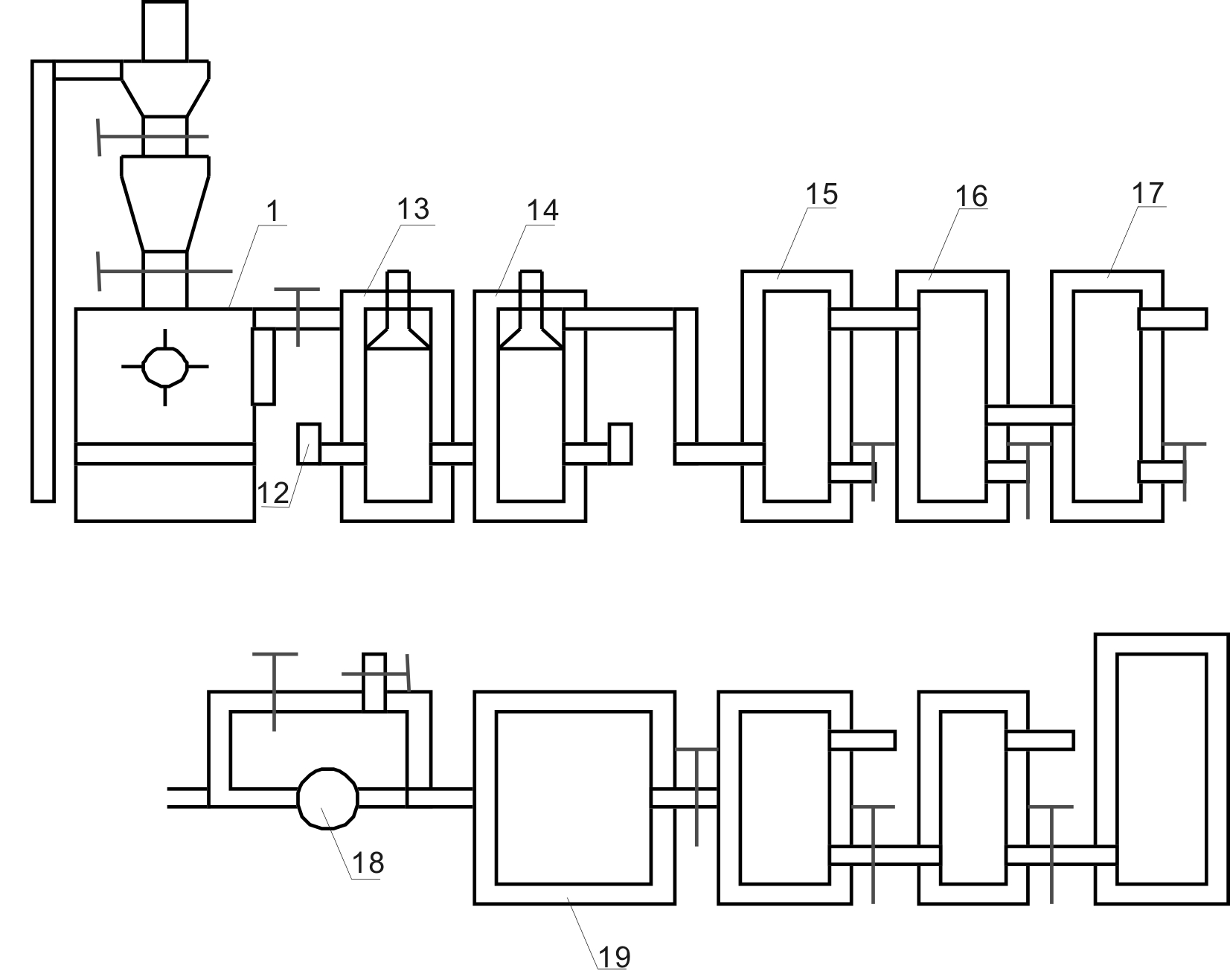

[0023] Such as figure 1 As shown, a method for preparing combustible gas from municipal solid waste and plant waste, first classifies municipal solid waste and plant waste, selects metals, bricks, stones and glass, and dehydrates them under pressure. Garbage and plant waste are mixed and pulverized, sent to the synthesis tower body 1 of the synthesis tower and pyrolyzed at a temperature of 1100-1200°C, and the gas generated enters the water filter tank 13 through the exhaust pipe through the water-sealed mobile observer 12;

[0024] The gas entering the water filter tank 13 is cooled to 25-35°C by normal temperature water, so that the tar substances in the mixed gas are converted into liquids, sink to the bottom of the water filter tank 13, and flow out through the bottom of the tank;

[0025] The gas filtered by the water filter tank 13 enters the CO that is added with lime water. 2 Filter 14, supplying water through the water pump, removes CO in the mixed gas 2 , to cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com