System for preparing biomass rod-shaped particles

A preparation system and biomass technology, applied in the field of briquette fuel preparation system, can solve the problems of unfavorable mass production, storage, transportation and use of briquette fuel, and achieve the effect of convenient transportation and storage and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

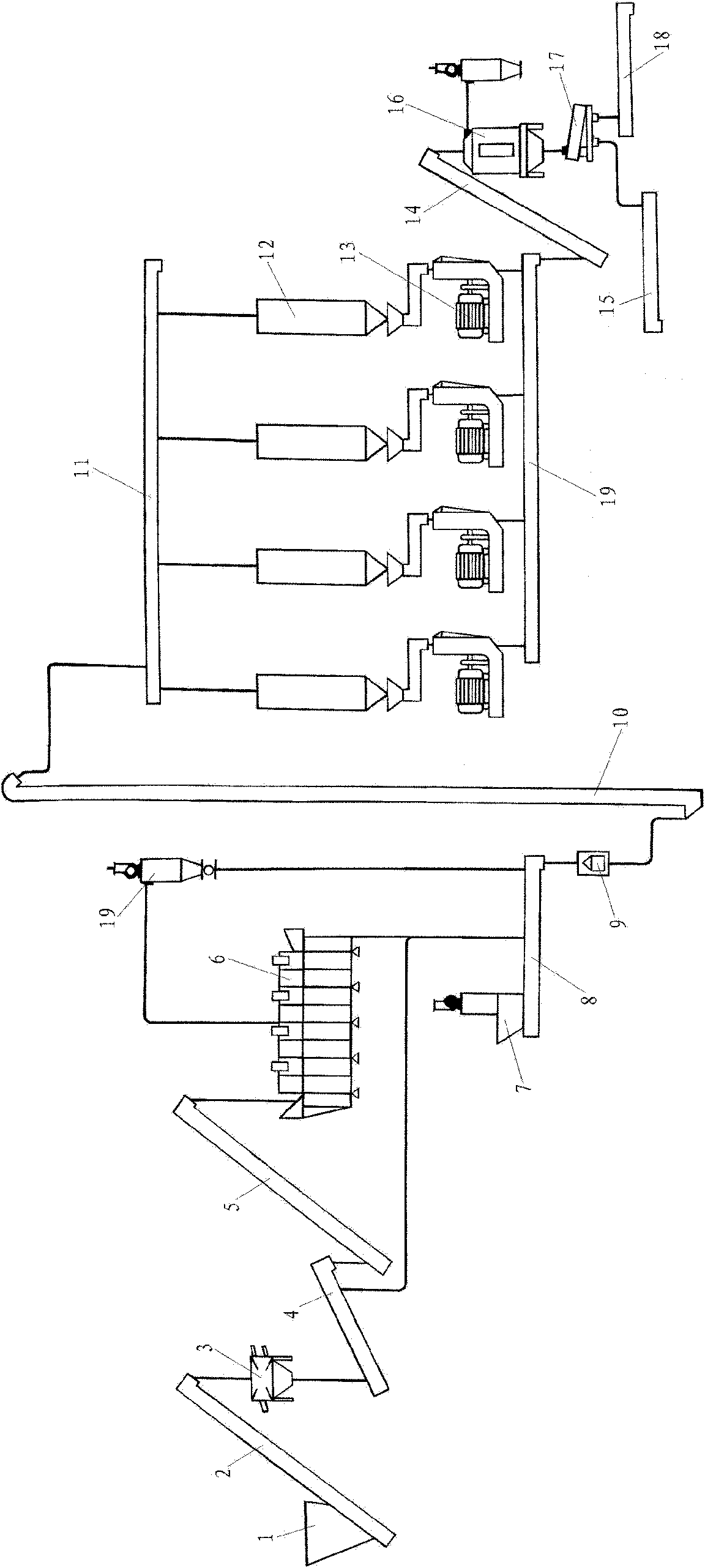

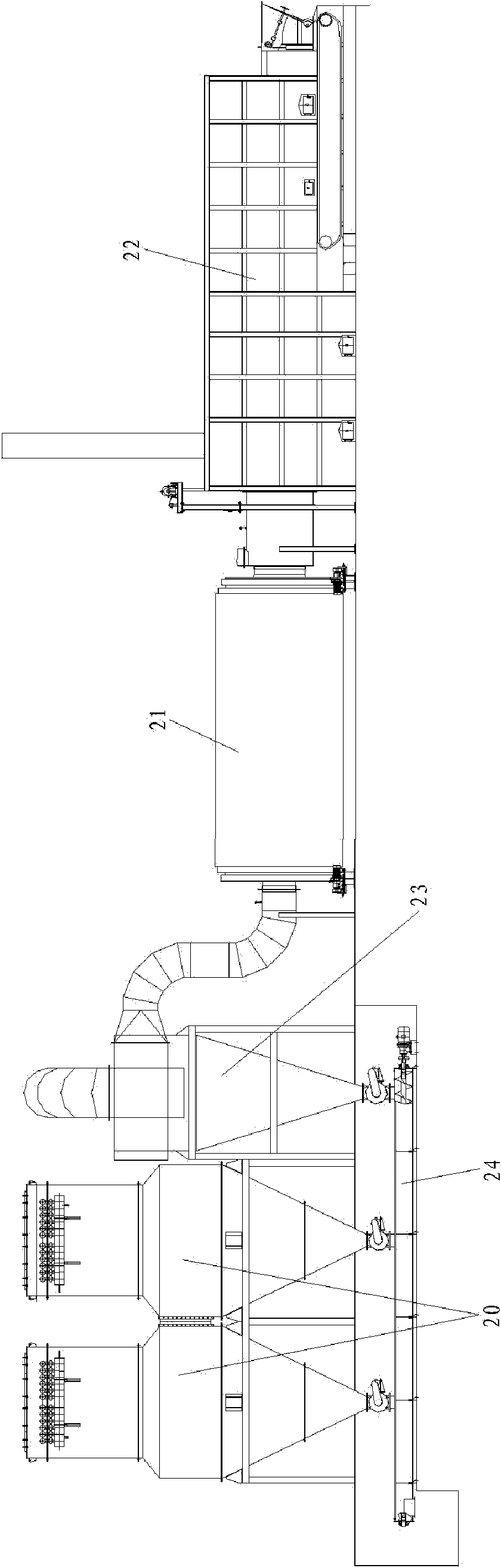

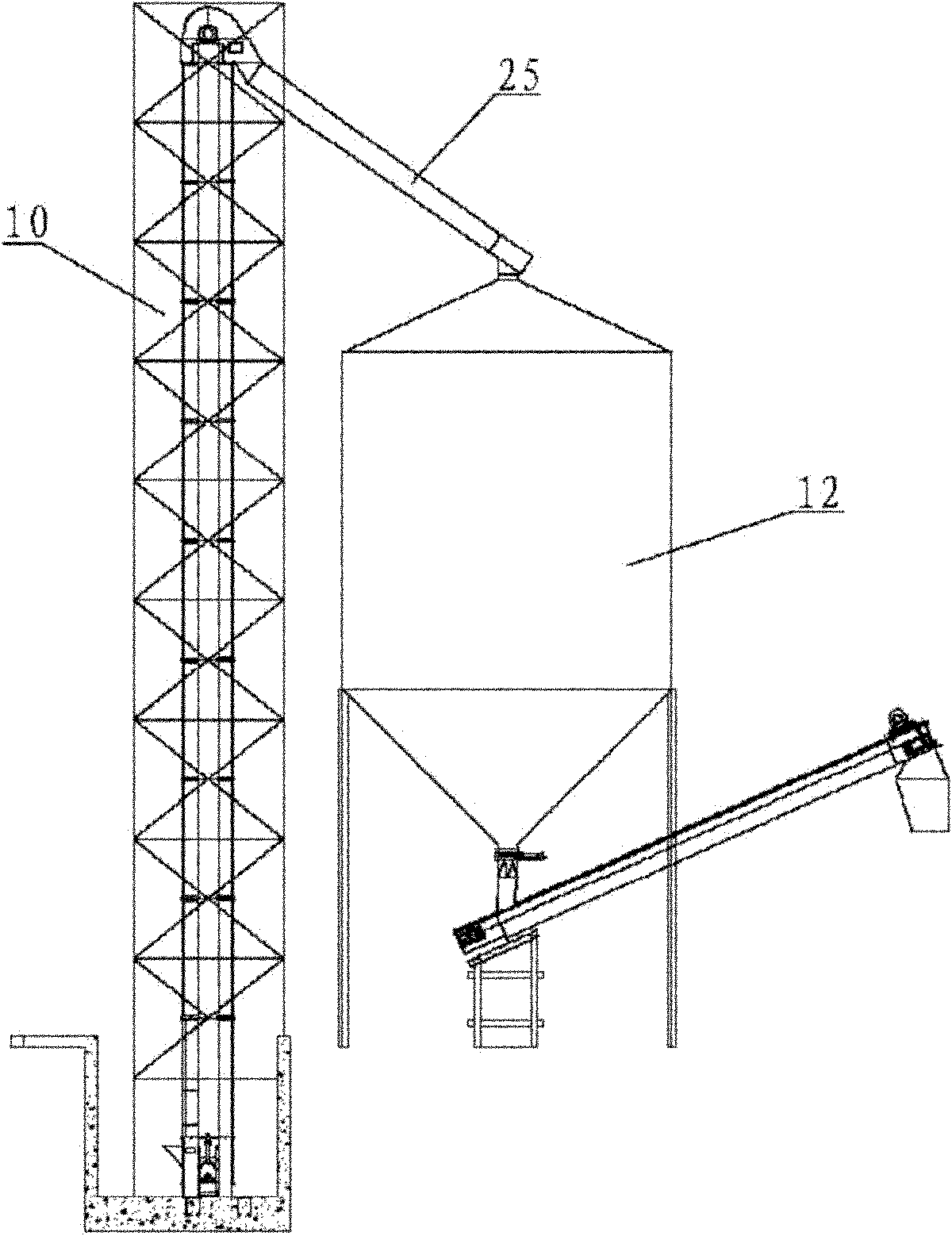

[0020] Such as figure 1 As shown, the present invention is a preparation system of biomass rod-shaped particles, which is composed of a conveying device, an initial cleaning screen, a drying system, a silo, a cooling device, a vibrating classifying screen, a pulverizer, and a permanent magnet cylinder.

[0021] 1. The conveying device is used to convey biomass materials or fuels, including scraper machine 2 or 5 or 8 or 11, auger 4 or 15, bucket elevator 10, belt conveyor 19, bucket belt conveyor 14, etc. A scraper machine 2 is arranged between the feeding port 1 and the initial cleaning screen 3, an auger 4 and a scraper machine 5 are arranged between the initial cleaning screen 3 and the drying system, and a scraper machine 5 is arranged between the feeding port 7 and the permanent magnet cylinder 9. The scraper machine 8 is arranged, the scraper machine 11 is arranged between the bucket elevator 10 and the silo 12, the belt conveyor 19 is arranged below the granulator 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com