Method for extracting almond protein by microwave

A technology of almond protein and almonds, which is applied to the protein composition of vegetable seeds, protein food ingredients, food science, etc., can solve the problems of low extraction rate, high energy consumption, and long extraction time, and achieve high extraction rate and long extraction time. Short, the effect of maintaining functional properties and nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for microwave extraction of almond protein, comprising the steps of:

[0021] (1) Crush the degreased almond residue through a 40-mesh sieve, accurately weigh a certain amount of almond residue powder, and dissolve it in distilled water at room temperature; the mass ratio of the almond residue powder to water is 1:30;

[0022] (2) Under the conditions of microwave power 350W, frequency 915MHz, temperature 55℃, pH=11, microwave extraction for 25min;

[0023] (3) Under the condition of 4000 rpm, centrifuge for 5 minutes, remove the sediment in the lower layer after centrifugation; let the upper liquid stand for 10 minutes, remove the oil layer on the liquid surface, and obtain substance A; the adjustment of the pH value is 1.5mol / L NaOH aqueous solution;

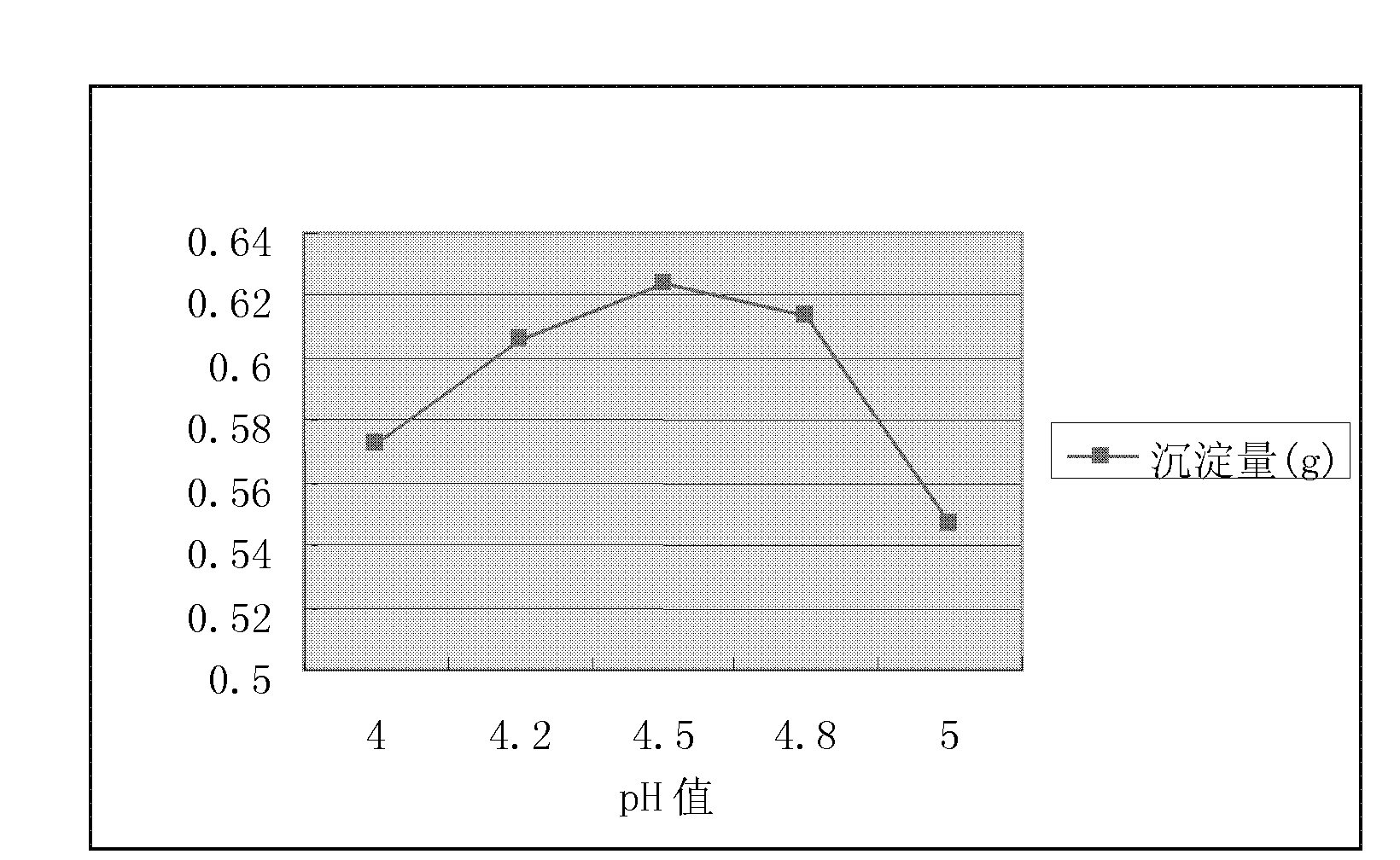

[0024] (4) Adjust substance A with 2% HCl aqueous solution, adjust its pH=4.5, and centrifuge for 3 minutes at 4000 rpm; remove the upper layer solution, take the precipitate, and obtain substance B;

[0025]...

Embodiment 2

[0027] A method for microwave extraction of almond protein, comprising the steps of:

[0028] (1) Crush the degreased almond residue through a 40-mesh sieve, accurately weigh a certain amount of almond residue powder, and dissolve it in distilled water at room temperature; the mass ratio of the almond residue powder to water is 1:35;

[0029] (2) Under the conditions of microwave power 250W, frequency 915 MHz, temperature 50°C, pH=11.5, microwave extraction for 15 minutes;

[0030] (3) Under the condition of 3500 rpm, centrifuge for 6 minutes, remove the sediment in the lower layer after centrifugation; let the upper liquid stand for 8 minutes, remove the oil layer on the liquid surface, and obtain substance A; the adjustment of the pH value is 0.5mol / L of NaOH aqueous solution;

[0031] (4) Adjust substance A with 3% HCl aqueous solution to make it pH = 4.5, and centrifuge it for 4 minutes at 3500 rpm; remove the upper layer solution, take the precipitate, and obtain substa...

Embodiment 3

[0034] A method for microwave extraction of almond protein, comprising the steps of:

[0035] (1) Crush the degreased almond residue through a 40-mesh sieve, accurately weigh a certain amount of almond residue powder, and dissolve it in distilled water at room temperature; the mass ratio of the almond residue powder to water is 1:40;

[0036] (2) Under the conditions of microwave power 150W, frequency 915MHz, temperature 45°C, pH=10.5, microwave extraction for 20 minutes;

[0037] (3) Under the condition of 4500 rpm, centrifuge for 4 minutes, remove the sediment in the lower layer after centrifugation; let the upper liquid stand for 5 minutes, remove the oil layer on the liquid surface, and obtain substance A; the pH value is adjusted using 1mol / L NaOH aqueous solution;

[0038] (4) Adjust substance A with 2% HCl aqueous solution to make it pH = 4.5, and centrifuge it for 2 minutes at 4500 rpm; remove the upper layer solution, take the precipitate, and obtain substance B;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com