Aqueous bi-phase system and application thereof to extraction of melamine from tomato ketchup

A two-phase system, melamine technology, applied in the fields of food science and analytical chemistry, can solve the problems of cumbersome operation, difficulty in popularization, low sensitivity, etc., and achieve the effects of convenient operation, overcoming easy emulsification, and sensitive detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

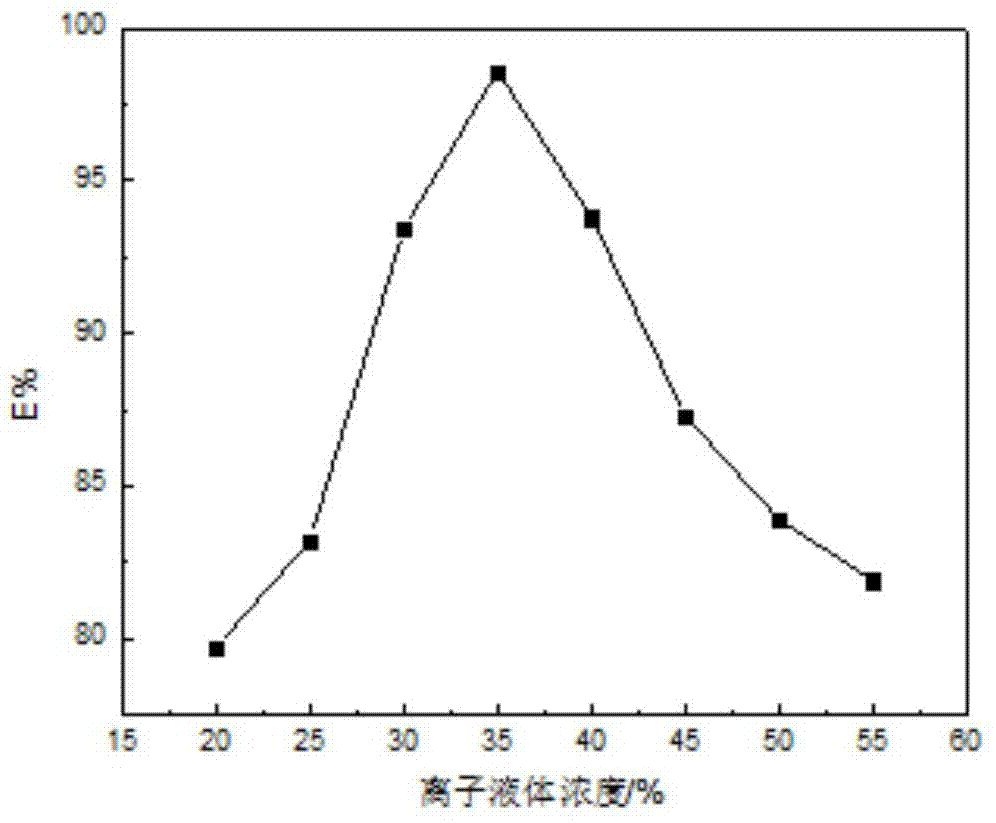

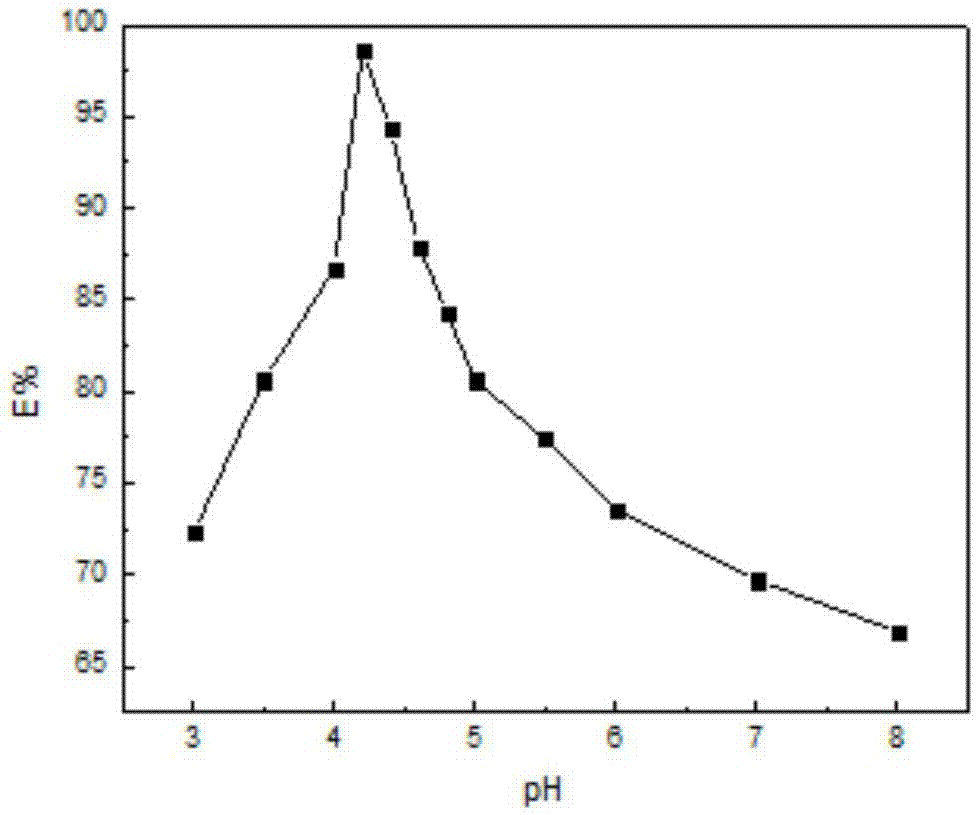

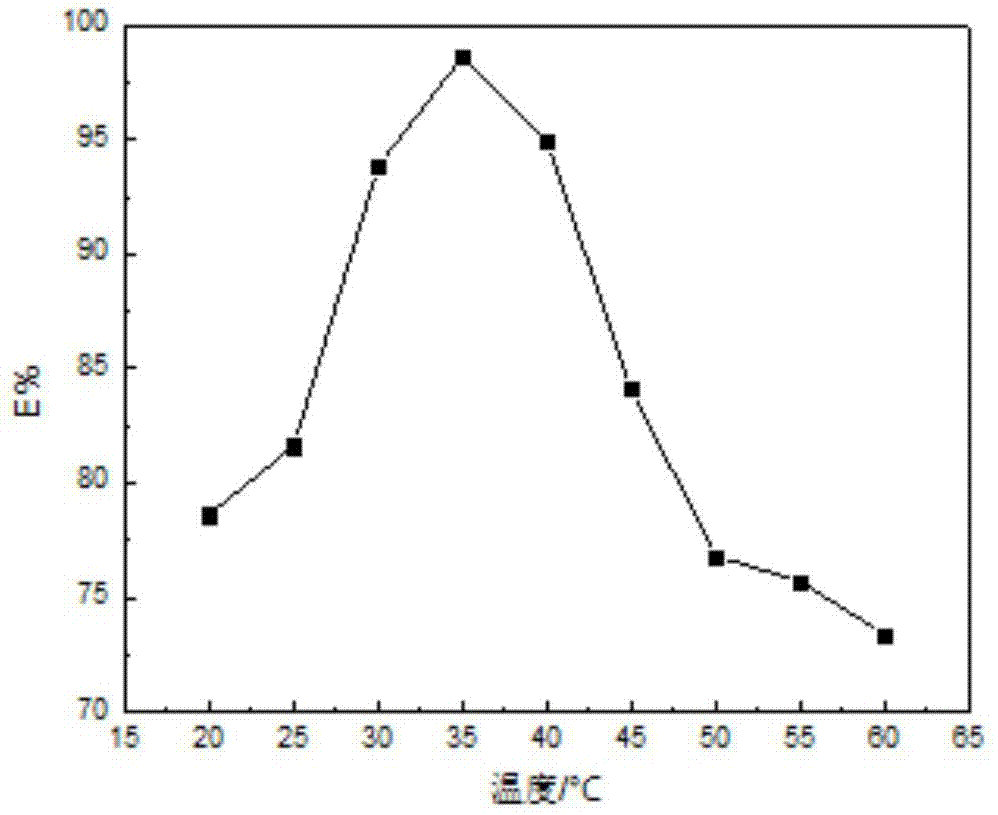

[0049] Take 3.5g of 1-butyl-4-methylpyridine tetrafluoroborate and place it in a centrifuge tube, add 2.6g of sodium dihydrogen phosphate and 3.9g of distilled water, mix well, then add 2g of the melamine solution to be tested, and heat at 35°C , shake at a constant temperature for 30 minutes at pH 4.2, separate the phases and let stand for extraction for 24 hours. After the phase separation is clear, measure the concentration of residual melamine in the water phase, and calculate the extraction rate of melamine from the content of melamine in the water phase before and after extraction to be 98.6%.

[0050] Implementation column 2

[0051] The preparation method of this example is the same as that of Example 1, except that the ionic liquid of the organic matter is different. In this example, the organic matter is ethanol, and the other conditions remain unchanged.

[0052] In order to detect the extraction effect of the present invention on melamine, an extraction experiment...

Embodiment 7

[0066] The preparation method of this example is the same as that of Example 1, except that the amount of ionic liquid is different. In this example, 2.0 g of 1-butyl-4-picoline tetrafluoroborate is used, and other conditions remain unchanged.

[0067] In order to detect the extraction effect of the present invention on melamine, an extraction experiment was carried out on melamine, and the extraction rate was 79.7%.

[0068] Implementation Column 8

[0069] The preparation method of this example is the same as that of Example 1, except that the amount of ionic liquid is different. In this example, 5.5 g of 1-butyl-4-picoline tetrafluoroborate is used, and other conditions remain unchanged.

[0070] In order to detect the extraction effect of the present invention on melamine, an extraction experiment was carried out on melamine, and the extraction rate was 81.9%.

[0071] Implementation column 9

[0072] The preparation method of this example is the same as that of Example ...

Embodiment 10

[0075] The preparation method of this example is the same as that of Example 1, except that the pH value is different. The pH in this example is 8.0, and the other conditions remain unchanged.

[0076] In order to detect the extraction effect of the present invention on melamine, an extraction experiment is carried out on melamine, and the extraction rate is 66.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com