Method for extracting lentinan by virtue of ultrasonic coupling subcritical water

A technology of lentinan and subcritical water, which is applied in the field of plant fungal polysaccharide extraction, can solve the problems of not being able to reflect the advantages of subcritical water and low mass transfer efficiency, and achieve the goal of improving ultrasonic enhancement, high extraction yield, and strong solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Ultrasonic coupling subcritical water extraction method: dried shiitake mushrooms to constant weight are crushed and passed through a 40-mesh sieve, and the material is measured according to the liquid-to-solid ratio of 30mL / g. The pressure is 5MPa, the temperature is 190°C, the ultrasonic frequency is 20kHz, and the power density is 3.15W / cm 2 , the extraction time was 40min, and the extraction yield of mushroom polysaccharide was 34.0%.

Embodiment 2~6

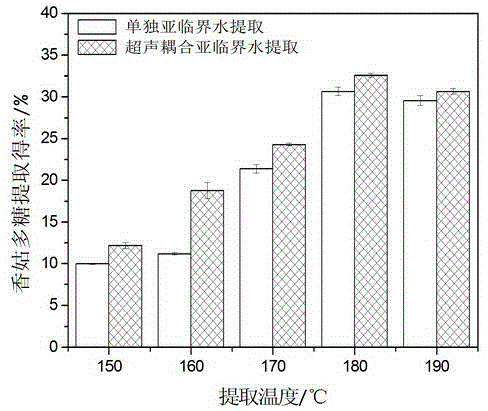

[0026] Ultrasonic coupling subcritical water extraction method: dried shiitake mushrooms to constant weight are crushed and passed through a 40-mesh sieve, and the material is measured according to the liquid-to-solid ratio of 30mL / g. The pressure is 5MPa, the temperature is 150, 160, 170, 180, 190°C, the ultrasonic frequency is 40kHz, and the power density is 3.95W / cm 2 , the extraction time was 40min, and a separate subcritical water extraction was used as a comparison, and the extraction yield of mushroom polysaccharide was as follows figure 1 shown.

Embodiment 7~11

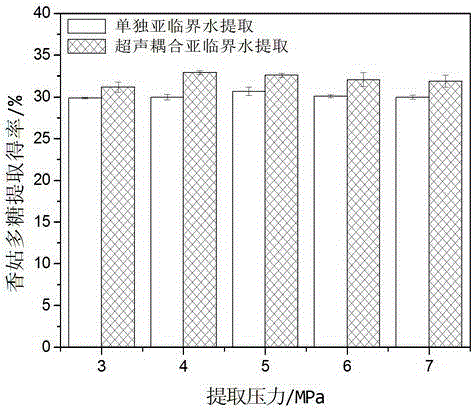

[0028] Ultrasonic coupling subcritical water extraction method: dried shiitake mushrooms to constant weight are crushed and passed through a 40-mesh sieve, and the material is measured according to the liquid-to-material ratio of 30mL / g, and then the material is put into the extraction kettle, vacuumed and degassed to a vacuum degree of 0.08MPa, and the extraction temperature The temperature is 180°C, the pressure of the extraction kettle is controlled at 3, 4, 5, 6, and 7MPa, the ultrasonic frequency is 20kHz, and the power density is 3.15W / cm 2 , the extraction time was 40min, and a separate subcritical water extraction was used as a comparison, and the extraction yield of mushroom polysaccharide was as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com