Large-thrust multiple acceleration type pneumatic ejector for carrier-based airplanes of airplane carrier

A carrier-based aircraft, accelerated technology, applied in the direction of launch / tow transmission, can solve the problems of unadjustable power, many operators, reduced air tightness, etc., to achieve adjustable power, high power conversion rate, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The ejection steps of the large-thrust multiplication speed-up type pneumatic carrier aircraft catapult of the present invention are as follows:

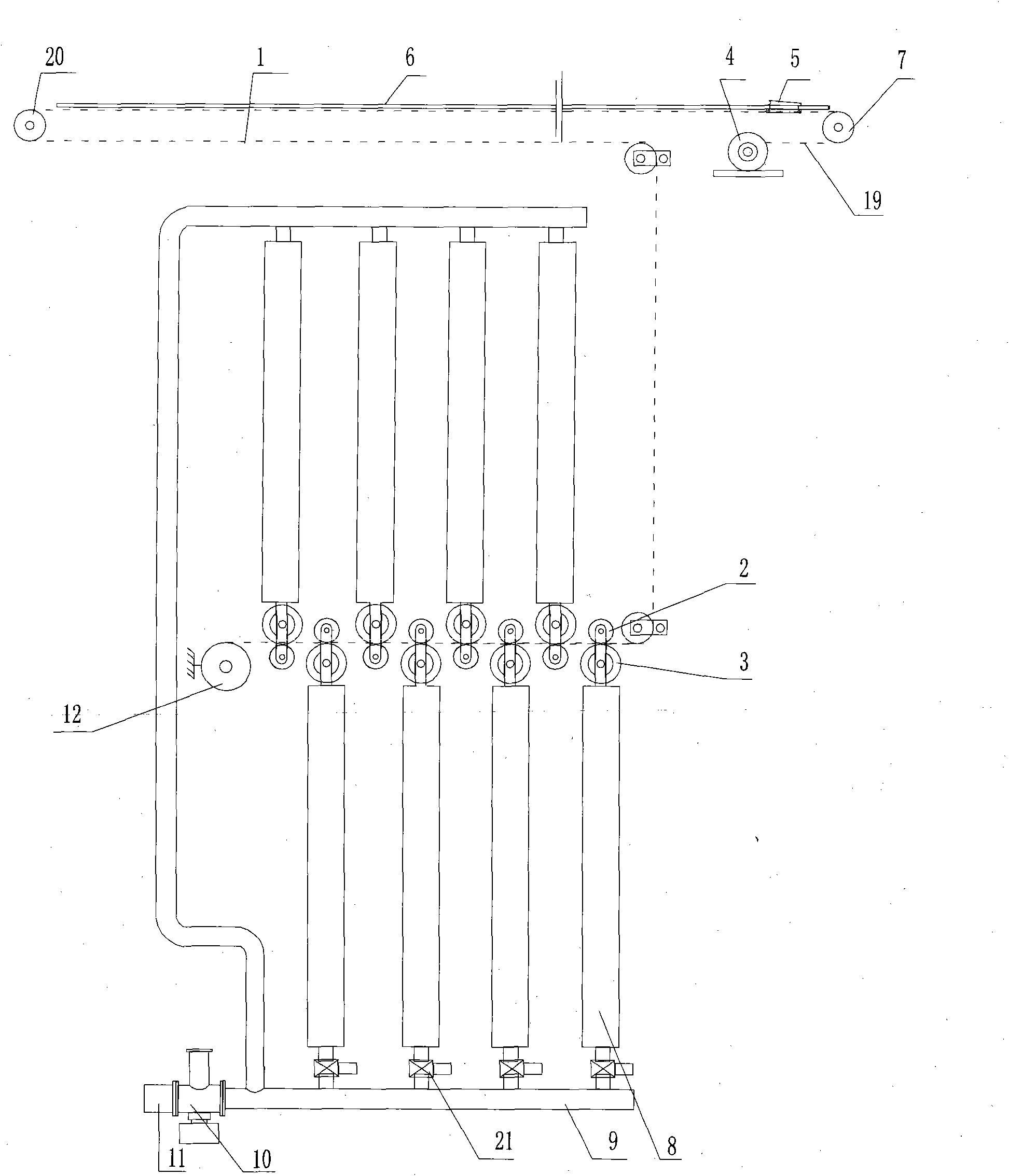

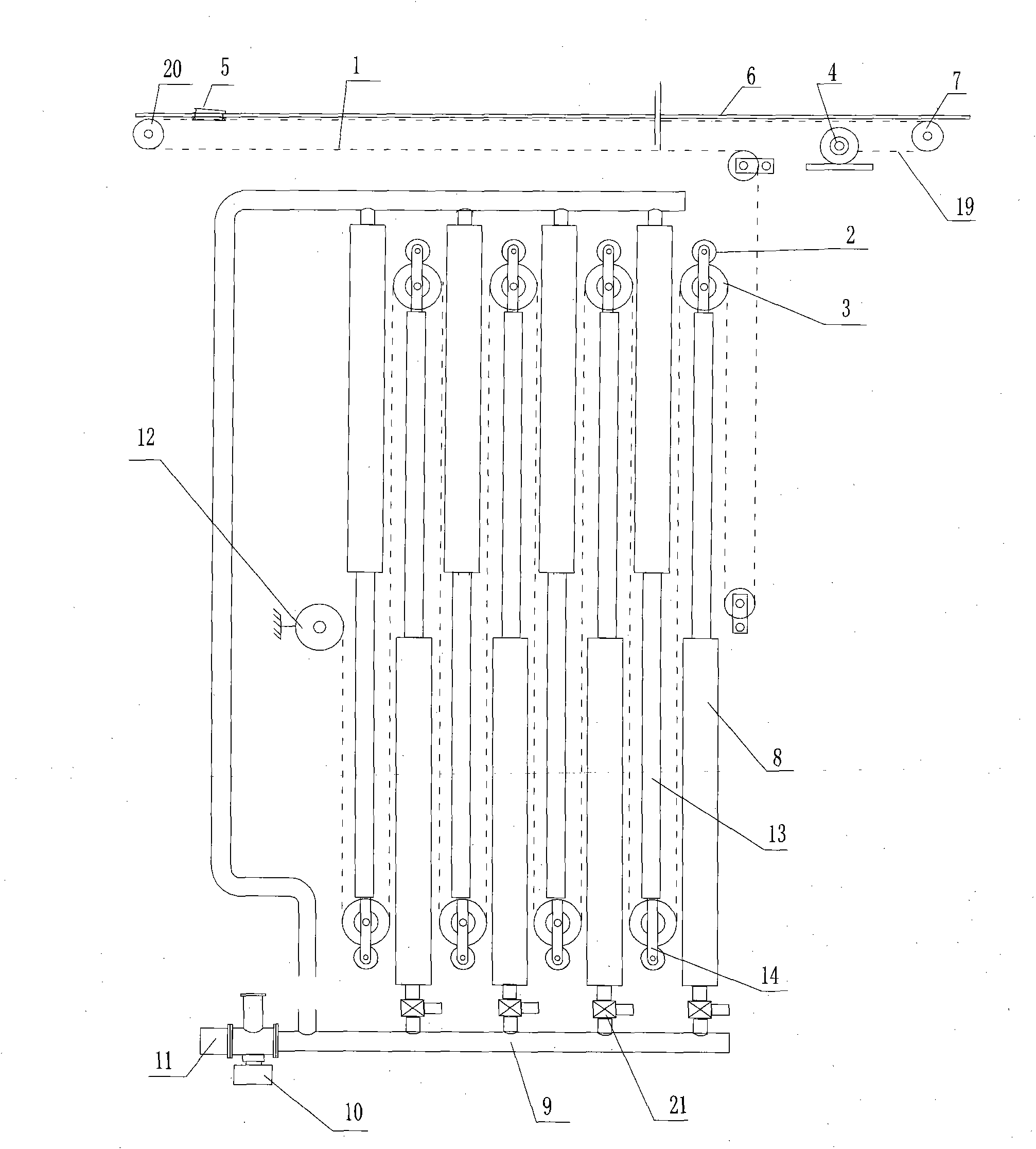

[0039] 1) The piston connecting rod is fully retracted into the cylinder body of the pneumatic cylinder, the wire rope is less bent, the homing winch is released, the shuttle is located at the take-off starting point of the take-off runway, and the shuttle is hooked to the ejected aircraft to take off and stand by;

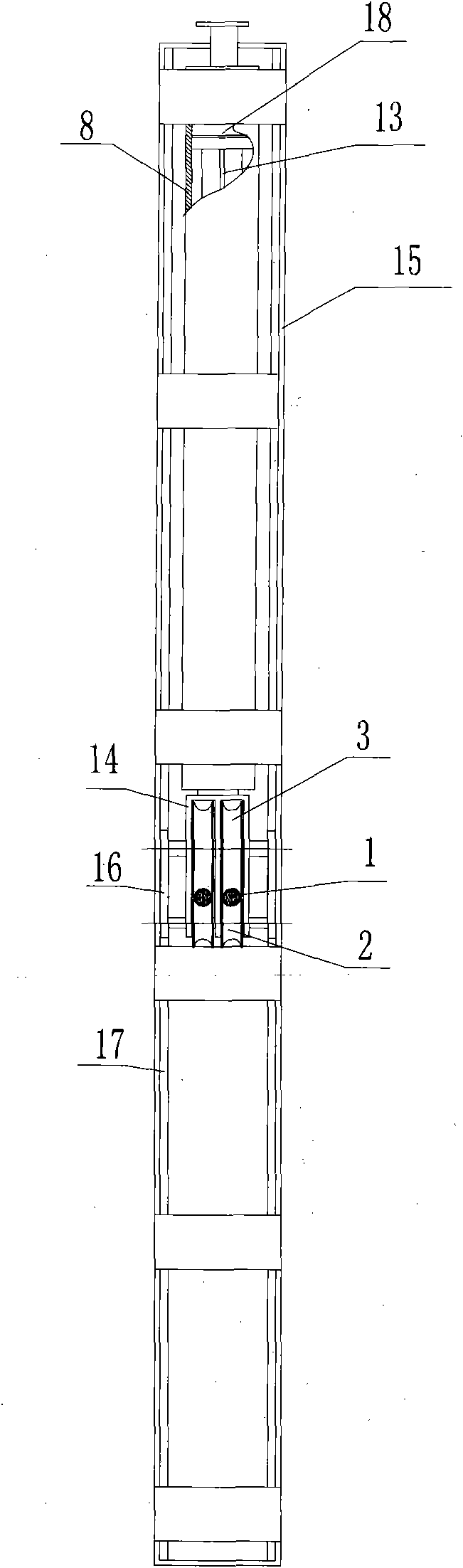

[0040] 2) When the take-off command is issued, the three-way valve is opened, and the high-pressure air source inflates the high-pressure air pipe through the three-way valve, and the high-pressure air pipe inflates each air cylinder respectively. The driving pulley at the end pushes the wire rope to bend, and the wire rope is arranged in an S shape between the pneumatic cylinders.

[0041] The S-shaped bending of the wire rope shortens the length of the wire rope on the take-off runway, so the traction shuttle q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com