Technology method and device for preparing ammonium diuranate

A technology for the preparation of ammonium diuranate, which is applied in chemical instruments and methods, uranium compounds, inorganic chemistry, etc., to achieve the effects of easy self-control operation, less equipment, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

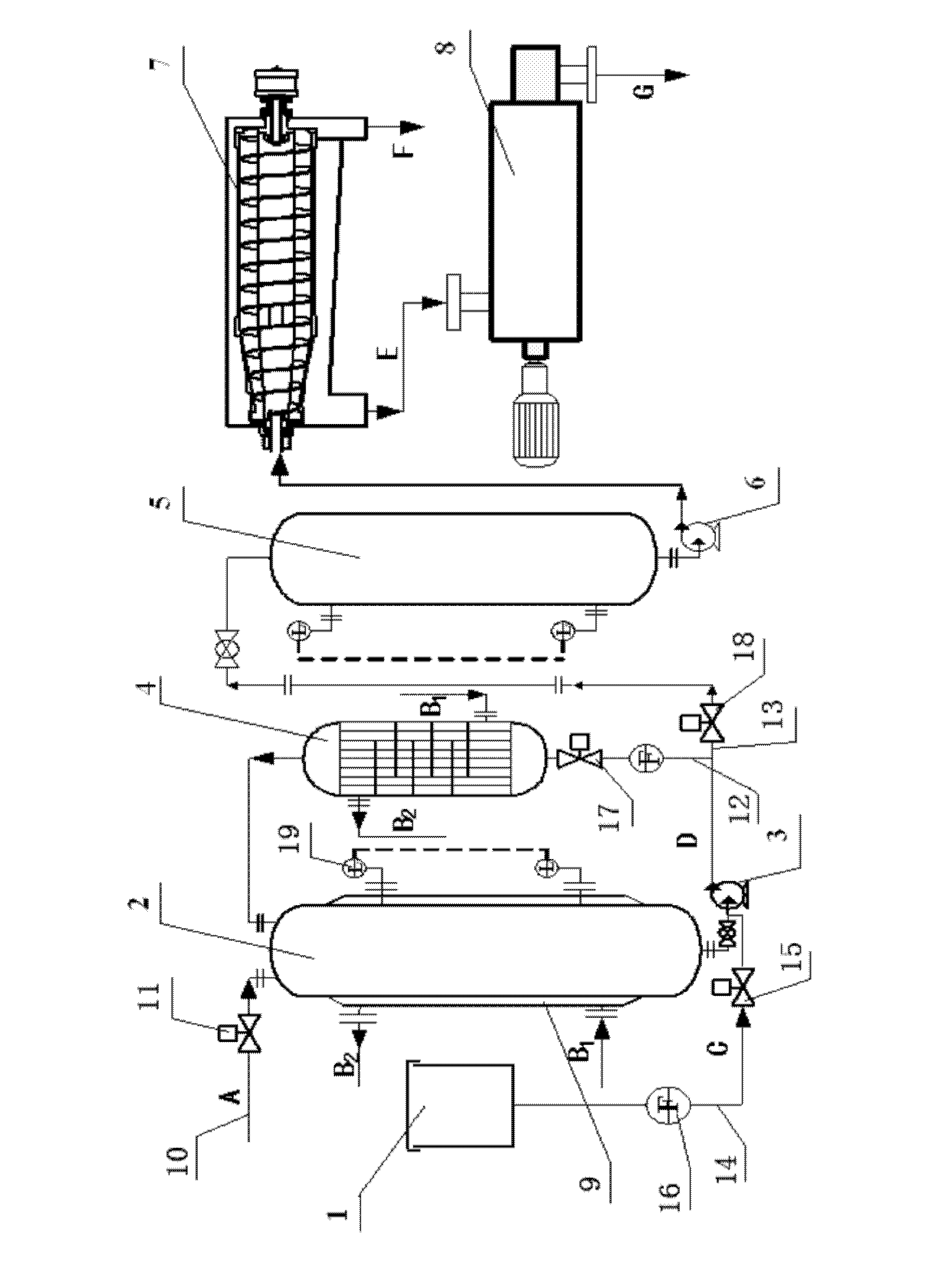

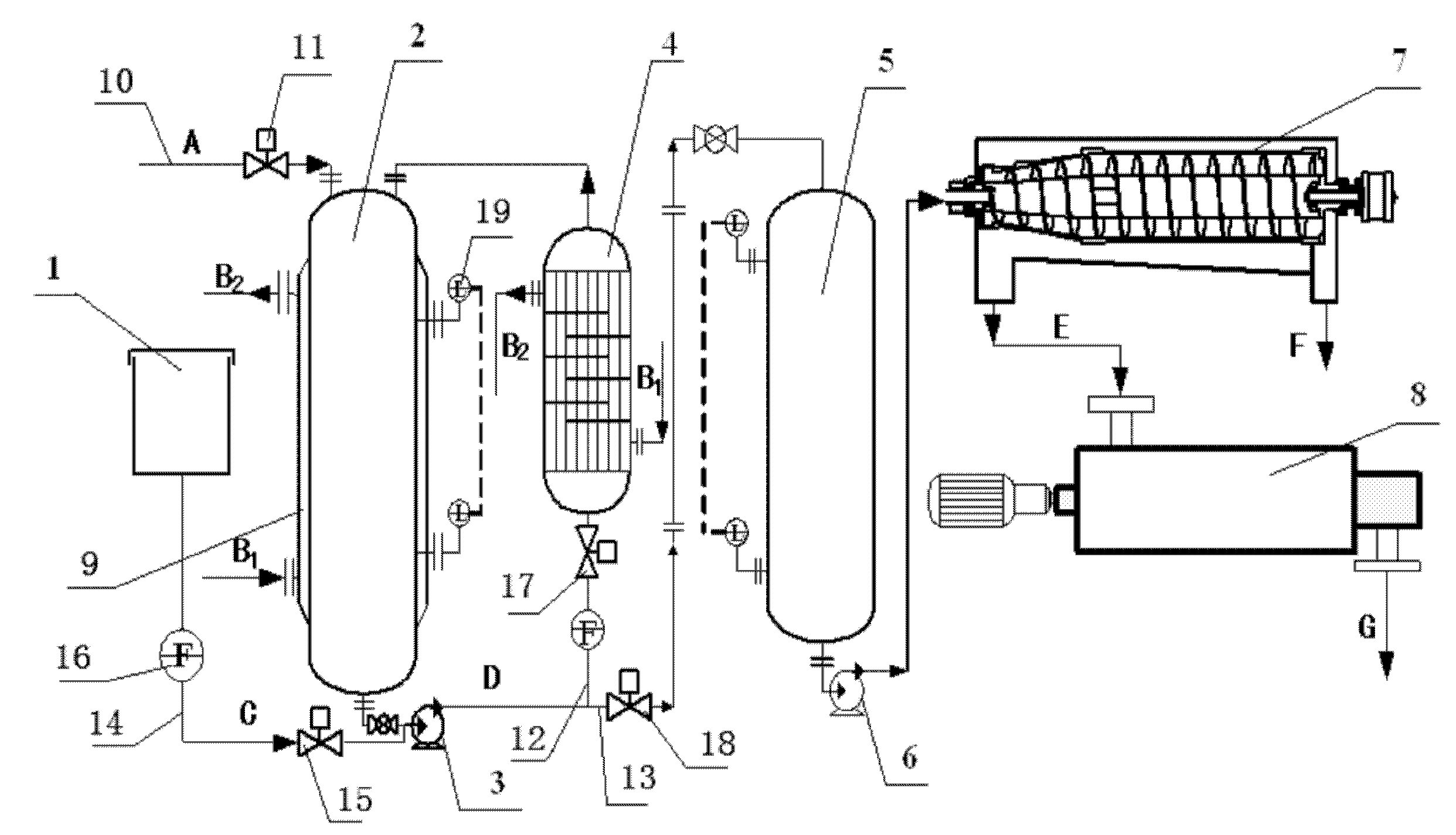

Method used

Image

Examples

Embodiment 1

[0025] The batch precipitation preparation process of ammonium diuranate (ADU) according to the present invention can realize industrial-scale production, which includes the following steps:

[0026] (1) Preparation of raw material liquid: will be filled with UF 6 The vessel is heated to 70℃ to make UF 6 It is gasified and transported to the hydrolysis column via pipeline. Deionized water is added to the top of the hydrolysis column with UF 6 Reverse gas contact, hydrolysis reaction, UO with a uranium concentration of 100g / L 2 F 2 Solution

[0027] (2) ADU precipitation process: add 60 liters of UO with a uranium concentration of 100 g / L obtained in step (1) above 2 F 2 Add 25% by mass ammonia water to the solution to control NH 3 The molar ratio to U ion is 1:30, the ammonia addition time is 6 minutes, the reaction temperature is 35°C, and the precipitation time is 7 minutes, to obtain ADU slurry;

[0028] (3) Aging treatment: The ADU slurry obtained in the above step (2) is stirred ...

Embodiment 2

[0034] The batch precipitation preparation process of ammonium diuranate (ADU) according to the present invention can realize industrial-scale production, which includes the following steps:

[0035] (1) Preparation of raw material liquid: will be filled with UF 6 The vessel is heated to above 70℃ to make UF 6 It is gasified and transported to the hydrolysis column via pipeline. Deionized water is added to the top of the hydrolysis column with UF 6 Reverse gas contact, hydrolysis reaction, UO with a uranium concentration of 70g / L 2 F 2 Solution

[0036] (2) ADU precipitation process: add 20 liters of UO with a uranium concentration of 70 g / L obtained in step (1) above 2 F 2 Add 20% by mass ammonia water to the solution to control NH 3 The molar ratio to U ion is 1:24, the ammonia addition time is 3 minutes, the reaction temperature is 20°C, and the precipitation time is 3 minutes to obtain ADU slurry;

[0037] (3) Aging treatment: the ADU slurry obtained in the above step (2) is stirr...

Embodiment 3

[0043] The batch precipitation preparation process of ammonium diuranate (ADU) according to the present invention can realize industrial-scale production, which includes the following steps:

[0044] (1) Preparation of raw material liquid: will be filled with UF 6 The container is heated to above 70℃ to make UF 6 It is gasified and transported to the hydrolysis column via pipeline. Deionized water is added to the top of the hydrolysis column with UF 6 Reverse gas contact, hydrolysis reaction, UO with a uranium concentration of 130g / L 2 F 2 Solution

[0045] (2) ADU precipitation process: add 100 liters of UO with a uranium concentration of 130 g / L obtained in step (1) above 2 F 2 Add 28% by mass ammonia to the solution to control NH 3 The molar ratio to U ion is 1:34, the ammonia addition time is 10 minutes, the reaction temperature is 50°C, and the precipitation time is 10 minutes, to obtain ADU slurry;

[0046] (3) Aging treatment: the ADU slurry obtained in the above step (2) is st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com